A preparing method of a nanometer Fe2O3/rGO composite material and applications of the composite material

A composite material, fe2o3 technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor conductivity, poor lithium-ion battery effect, poor volume expansion coefficient, etc. The effect of stable product quality, uniform appearance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a) Add 1.1g FeSO 4 ·7H 2 O is dissolved in the mixed liquid of 80ml water and 20ml glycerol to form mixed solution A;

[0036] b) Disperse 0.04 graphite oxide in 40ml of water and ultrasonically disperse for 2 hours to form solution B;

[0037] c) Add solution B to mixed solution A, and stir to form mixed solution C;

[0038] d) Put the mixed solution C into an autoclave, place the autoclave at a temperature of 180°C for 10 hours to obtain the product;

[0039] e) The product was washed several times with absolute ethanol and water, and dried in a vacuum oven at 70°C for several hours to obtain the nano-Fe 2 o 3 / rGO composites.

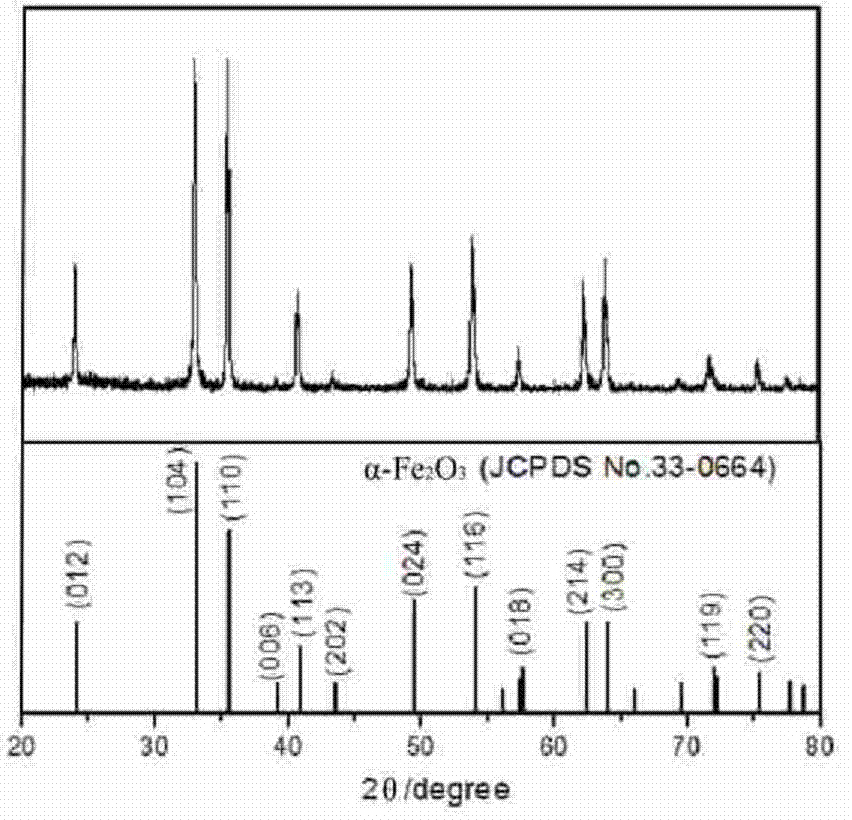

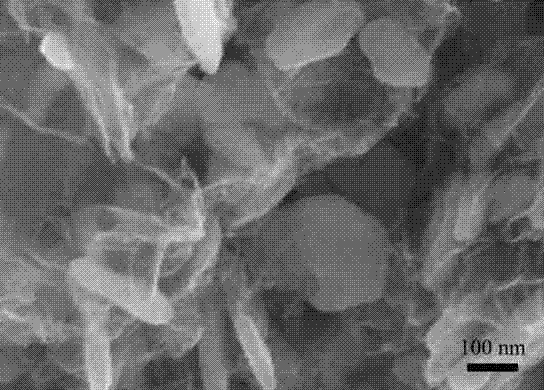

[0040] The product was identified as α-Fe by X-ray powder diffraction 2 o 3 , powder X-ray diffraction results as figure 1 shown; material morphology by scanning electron microscope, transmission electron microscope as figure 2 , shown in 3, it can be seen from the figure that the nanosheet α-Fe 2 o 3 uniformly embedded in graphene...

Embodiment 2

[0043] a) Add 1.1g FeSO 4 ·7H 2 O is dissolved in the mixed liquid of 70ml water and 20ml glycerol to form mixed solution A;

[0044] b) Disperse 0.04 graphite oxide in 40ml of water and ultrasonically disperse for 2 hours to form solution B;

[0045] c) Add solution B to mixed solution A, and stir to form mixed solution C;

[0046] d) Put the mixed solution C into an autoclave, place the autoclave at a temperature of 140° C. and react for 10 hours to obtain the product;

[0047] e) The product was washed several times with absolute ethanol and water, and dried in a vacuum oven at 70°C for several hours to obtain the nano-Fe 2 o 3 / rGO composites.

[0048] The resulting product was subjected to X-ray powder diffraction as figure 1 Similarly, the material morphology by scanning electron microscopy such as Figure 4 As shown, it can be seen from the figure that the nanosheet-like α-Fe 2 o 3 uniformly embedded in graphene.

Embodiment 3

[0050] a) Add 1.1g FeSO 4 ·7H 2 O is dissolved in the mixed liquid of 80ml water and 20ml glycerol to form mixed solution A;

[0051] b) Disperse 0.04 graphite oxide in 40ml water and ultrasonically disperse for 2.5h to form solution B;

[0052] c) Add solution B to mixed solution A, and stir to form mixed solution C;

[0053]d) Put the mixed solution C into an autoclave, place the autoclave at a temperature of 150° C. to react for 12 hours to obtain the product;

[0054] e) The product was washed several times with absolute ethanol and water, and dried in a vacuum oven at 60°C for several hours to obtain the nano-Fe 2 o 3 / rGO composites.

[0055] The resulting product is identified through X-ray powder diffraction and scanning electron microscopy (with the nano-Fe prepared in Example 1 2 o 3 / rGO composite material) it can be seen that it is nano-Fe 2 o 3 / rGO composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com