Prepn of conductive composite nanometer titanium nitride-alumina material

A nano-titanium nitride and composite material technology, applied in the direction of oxide conductors, non-metallic conductors, etc., can solve the problems of local component deviation, additive phase agglomeration, and less composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

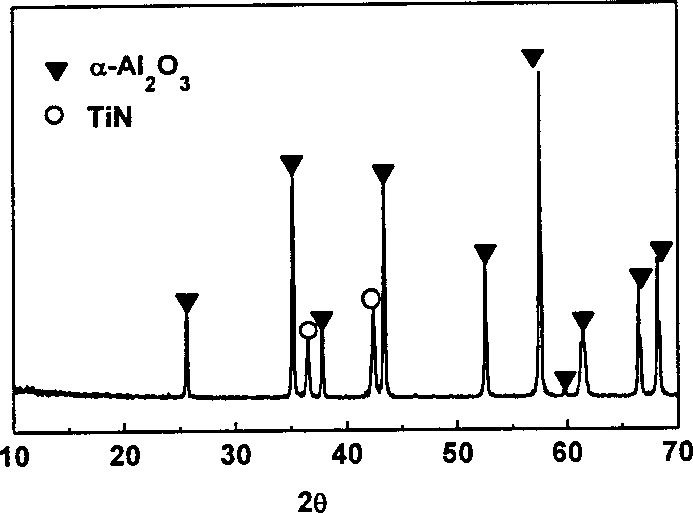

[0030] Example 1 25 vol% TiN-75 vol% Al 2 o 3 Preparation of composite materials

[0031] Get butyl titanate 92g, aluminum nitrate (Al(NO 3 ) 3 .9H 2 O) 266g was dissolved in 1200ml absolute ethanol solution, and the absolute ethanol solution of butyl titanate and aluminum nitrate was added dropwise to 6M dilute ammonia solution under vigorous stirring, hydrolyzed and precipitated at 30°C for 15 hours , filter the hydrolyzed and precipitated product, wash with distilled water to remove impurities, and wash twice with absolute ethanol, dry the filter cake at 120°C for 8h, grind, pass through a 200-mesh sieve, and then calcined at 450°C for 2h. Put the obtained nano-titania-alumina composite powder into a quartz crucible, put it into a tubular atmosphere furnace, feed ammonia gas, the flow rate of ammonia gas is 2 liters / minute, and the temperature is raised to 950 ° C, and the heating rate is 15 ° C / minute. It was kept at this temperature for 4 hours, and then naturally...

Embodiment 2

[0033] Example 2 20 vol% TiN-80 vol% Al 2 o 3 Preparation of composite materials

[0034] Get butyl titanate 46g, aluminum chloride (AlCl 3 .6H 2O) 164g was dissolved in 1000ml of absolute ethanol solution, and the absolute ethanol solution of butyl titanate and aluminum chloride was added dropwise to 4M dilute ammonia solution under vigorous stirring, hydrolyzed and precipitated at 45°C for 8 hours, filter the hydrolyzed and precipitated product, wash with distilled water to remove impurities, and wash twice with absolute ethanol, dry the filter cake at 120°C for 8h, grind, pass through a 200-mesh sieve, and then calcined at 450°C for 2h. Put the obtained nano-titania-alumina composite powder into a quartz crucible, put it into a tubular atmosphere furnace, feed ammonia gas, the flow rate of ammonia gas is 1 liter / min, and the temperature is raised to 900 ° C, and the heating rate is 10 ° C / minute. It was kept at this temperature for 5 hours, and then naturally cooled ...

Embodiment 3

[0036] Example 3 10 vol% TiN-90 vol% Al 2 o 3 Preparation of composite materials

[0037] Take 30g of isopropyl titanate and 68g of aluminum isopropoxide dissolved in 500ml of absolute ethanol solution, add the absolute ethanol solution drop by drop to distilled water under vigorous stirring, filter the hydrolyzate, wash with distilled water for two Once to remove impurities, and then washed twice with absolute ethanol, the filter cake was dried at 120°C for 10h, ground, passed through a 200-mesh sieve, and then calcined at 450°C for 4h. Put the obtained nano-titania-alumina composite powder into a quartz crucible, put it into a tubular atmosphere furnace, feed ammonia gas, the flow rate of ammonia gas is 3 liters / min, and the temperature is raised to 850 °C, and the heating rate is 10 °C / min. minute. It was kept at this temperature for 5 hours, and then naturally cooled to room temperature under flowing ammonia gas. A nanometer titanium nitride-alumina composite powder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com