Preparation and application of nanometer composite material based on porphyrin metal organic framework and ternary sulfide

A metal-organic framework, nanocomposite technology, applied in organic compound/hydride/coordination complex catalysts, chemical/physical processes, water pollutants, etc., can solve problems such as limiting the types of dye adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

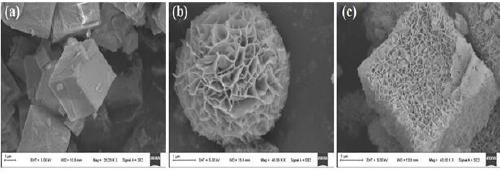

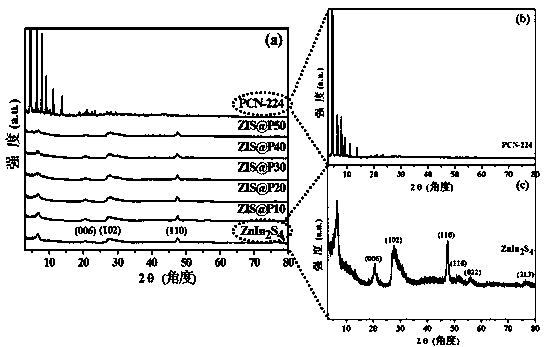

[0038] Embodiment 1, ZnIn 2 S 4 Preparation and performance research of @PCN-224(10%)

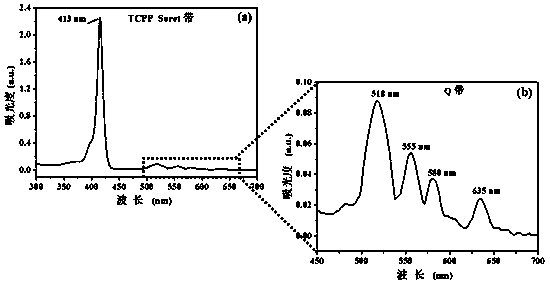

[0039] (1) Preparation of 5,10,15,20-tetrakis(4-carboxyphenyl)porphyrin (TCPP): Take 3.04 g (20.25 mmol) of 4-formylbenzoic acid and 1.4 g (20.25 mmol) of redistilled pyrrole , added to 60 mL of propionic acid, heated to reflux for 2 to 3 hours; then the reaction mixture was cooled to room temperature, and 75 mL of methanol was added, while cooling and stirring in an ice bath for 0.5 to 1 hour; centrifuged to obtain a precipitate, washed with methanol and heated distilled water Several times until the filtrate is clear. Finally, the obtained purple powder was dried in an oven at 60-80°C for 10-12 hours to obtain 0.79 g TCPP.

[0040] (2) Preparation of PCN-224: take 50mg TCPP, 78mg zirconium tetrachloride (ZrCl 4 ), 2700mg of benzoic acid (BA), ultrasonically dissolved in 10mL N,N-dimethylformamide, then heat-treated at 100-140°C for 45-50 hours, cooled to room temperature, centrifuged ...

Embodiment 2

[0045] Example 2, ZnIn 2 S 4 Preparation and performance research of @PCN-224 (20%)

[0046] (1) Preparation of TCPP: Same as Example 1;

[0047] (2) Preparation of PCN-224: Same as Example 1;

[0048] (3) Activation of PCN-224: Same as Example 1;

[0049] (4) ZnIn 2 S 4 Preparation of @PCN-224 nanocomposite: Take 0.106g PCN-224 powder and disperse it into a mixed solution of 15 mL N,N-dimethylformamide and 5mL glycerol; take 0.136g ZnCl 2 , 0.586g InCl 3 4H 2 O, 0.301g TAA, was added to the mixed solution, and stirred at room temperature for 1.5 hours; the obtained suspension was transferred to a polytetrafluoroethylene lining, and kept at 180°C for 10 hours, cooled to room temperature, and the obtained The solid product was washed several times with distilled water and ethanol, centrifuged to separate the precipitate, and dried at 60~80°C to obtain a solid powder that is ZnIn 2 S 4 @PCN-224 composite material, where the mass percentage of PCN-224 is 20%, marked as ...

Embodiment 3

[0052] Embodiment 3, ZnIn 2 S 4 Preparation and performance research of @PCN-224 (30%)

[0053] (1) Preparation of TCPP: Same as Example 1;

[0054] (2) Preparation of PCN-224: Same as Example 1;

[0055] (3) Activation of PCN-224: Same as Example 1;

[0056] (4) ZnIn 2 S 4 Preparation of @PCN-224 nanocomposite material: Take 0.181g PCN-224 powder and disperse it into a mixed solution of 15mL N,N-dimethylformamide and 5mL glycerol; take 0.136g ZnCl 2 , 0.586g InCl 3 4H 2 O, 0.301g TAA, was added to the mixed solution and stirred at room temperature for 1.5 hours; the obtained suspension was transferred to a polytetrafluoroethylene lining, and kept at 200°C for 8 hours, cooled to room temperature, and the resulting solid The product was washed several times with distilled water and ethanol, centrifuged to separate the precipitate, and dried at 60~80°C to obtain a solid powder that is ZnIn 2 S 4 @PCN-224 composite material, where the mass percentage of PCN-224 is 30%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com