Triblock copolymer PEO-PPO-PEO/calcium phosphate nanometer composite material and preparation method thereof

A technology of PEO-PPO-PEO and nano-composite materials, which is applied in the directions of non-active medical preparations, inorganic non-active ingredients, pharmaceutical formulations, etc., and can solve the problem that the triblock copolymer PEO-PPO-PEO is not much and so on. , to achieve the effect of broad use, convenient operation and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

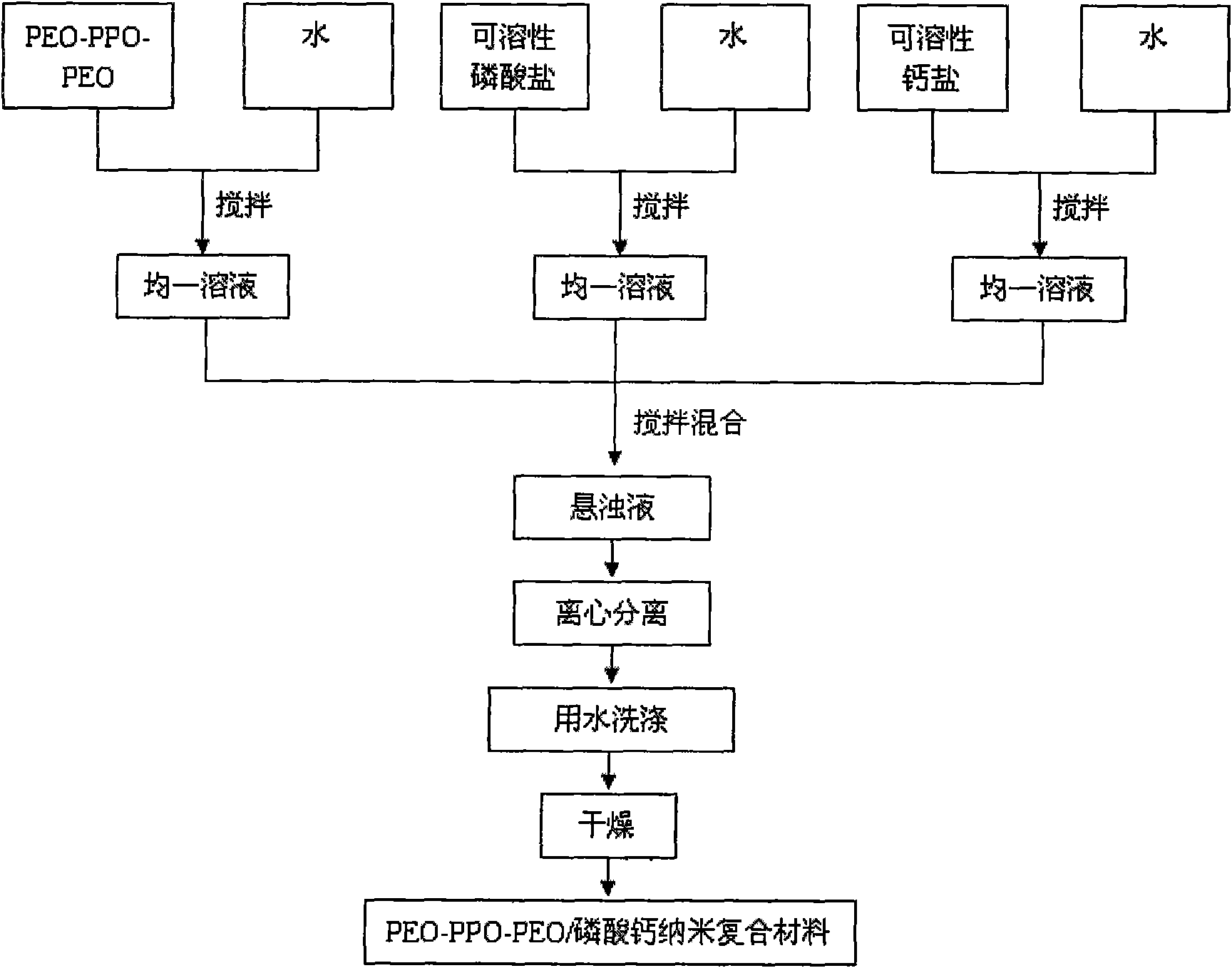

[0042] Embodiment 1: Preparation of triblock copolymer PEO-PPO-PEO / calcium phosphate nanocomposite material

[0043] Prepare P123 dispersion solution with a concentration of 2.5g / L and CaCl with a concentration of 0.5mol / L 2 aqueous solution and 0.5mol / L (NH 4 ) 3 PO 4 aqueous solution.

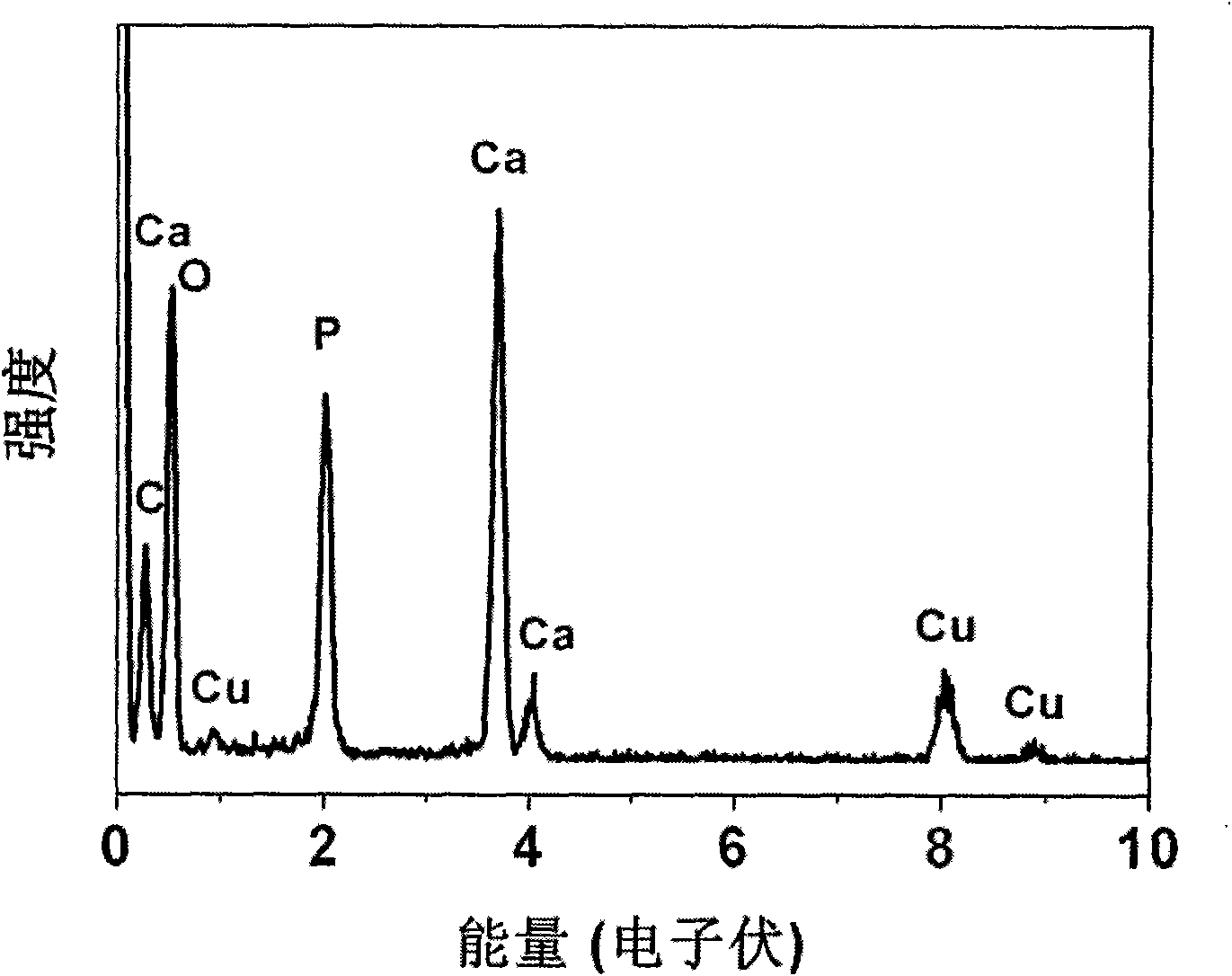

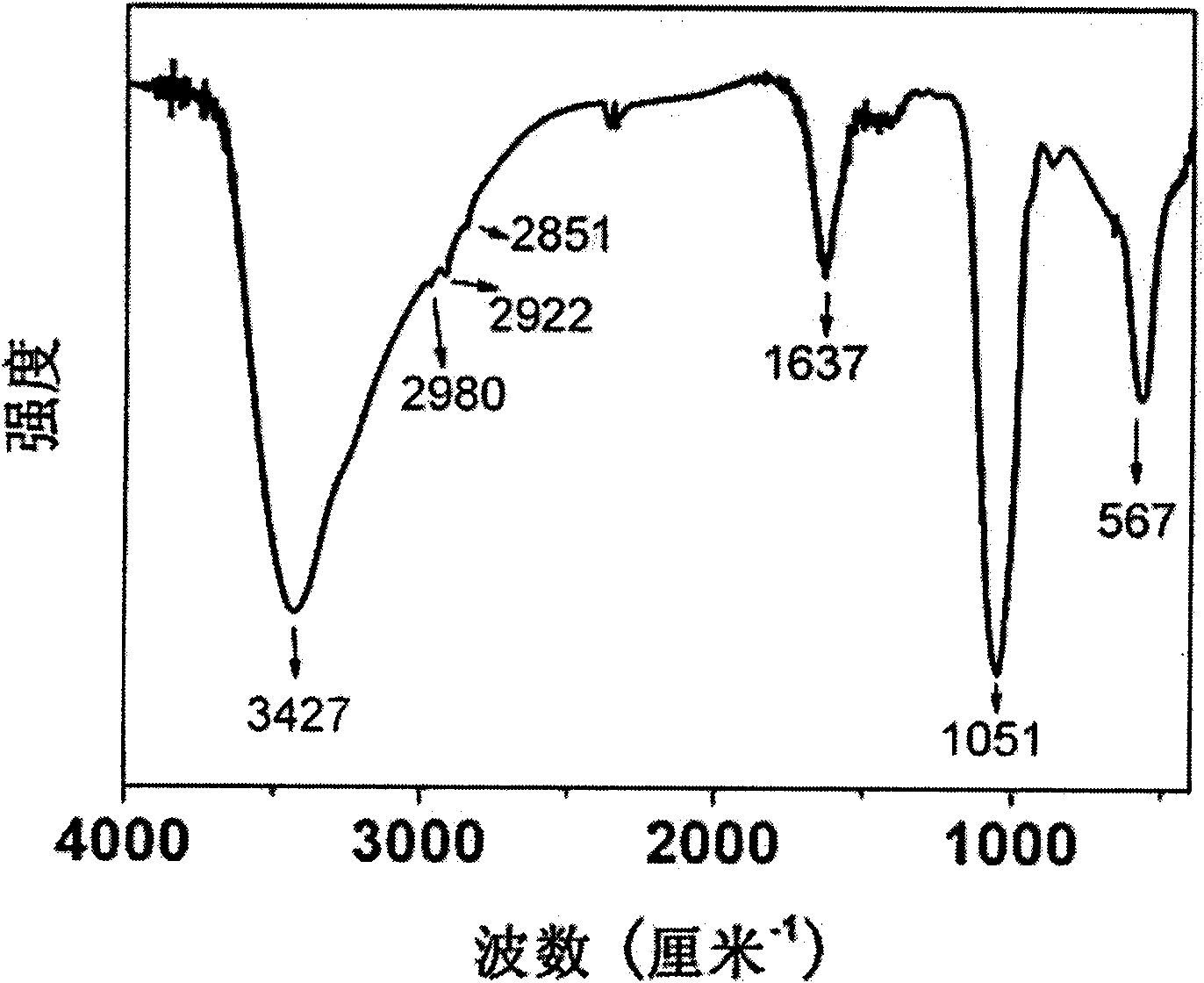

[0044] At room temperature, 0.100 g of P123 was added into 40 ml of water, stirred and dissolved at room temperature to obtain a uniformly dispersed solution. Add 1.5 ml of CaCl with a concentration of 0.5 mol / L to the solution 2 aqueous solution, and then add 0.9 ml of 0.5 mol / L (NH 4 ) 3 PO 4 aqueous solution to obtain a homogeneously dispersed suspension. After the reaction was complete, the product was separated by centrifugation, washed with water three times, and dried in air at 60° C. to obtain a P123-calcium phosphate nanocomposite material. Analysis shows that the morphology of the product is a porous structure, and the particle size is less than 100 nanometers. The prepara...

Embodiment 2

[0048] Example 2: Preparation of triblock copolymer PEO-PPO-PEO / calcium phosphate nanocomposite

[0049] At room temperature, 0.100 g of P123 was added into 40 ml of water, stirred and dissolved at room temperature to obtain a uniformly dispersed solution. Add 2.5 ml of Ca(NO 3 ) 2 aqueous solution, followed by the addition of 1.5 mL of Na at a concentration of 0.5 mol / L 3 PO 4 aqueous solution to obtain a homogeneously dispersed suspension. After the reaction is complete, the product is taken out, separated by centrifugation, washed with water three times, and dried in air at 60° C. to obtain a P123-calcium phosphate nanocomposite material. Analysis shows that the morphology of the product is a porous structure, and the particle size is less than 100 nanometers.

Embodiment 3

[0050] Example 3: Preparation of triblock copolymer PEO-PPO-PEO / calcium phosphate nanocomposite

[0051] At room temperature, 0.100 g of F127 was added into 20 ml of water, stirred and dissolved at room temperature to obtain a uniformly dispersed solution. Add 1.5 ml of 0.5 mol / L Ca(CH 3 COO) 2 aqueous solution, and then add 0.9 ml of 0.5 mol / L (NH 4 ) 2 HPO 4 aqueous solution to obtain a homogeneously dispersed suspension. After the reaction is complete, the product is taken out, separated by centrifugation, washed with water three times, and dried in air at 60° C. to obtain F127-calcium phosphate nanocomposite material. Analysis shows that the morphology of the product is a porous structure, and the particle size is less than 100 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com