Preparation method of porous carbon base multi-ingredient nanometer composite material

A nanocomposite material, porous carbon technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex process methods, lack of advantages, inability to provide pore structures, etc., to achieve the process process Simple, low cost and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

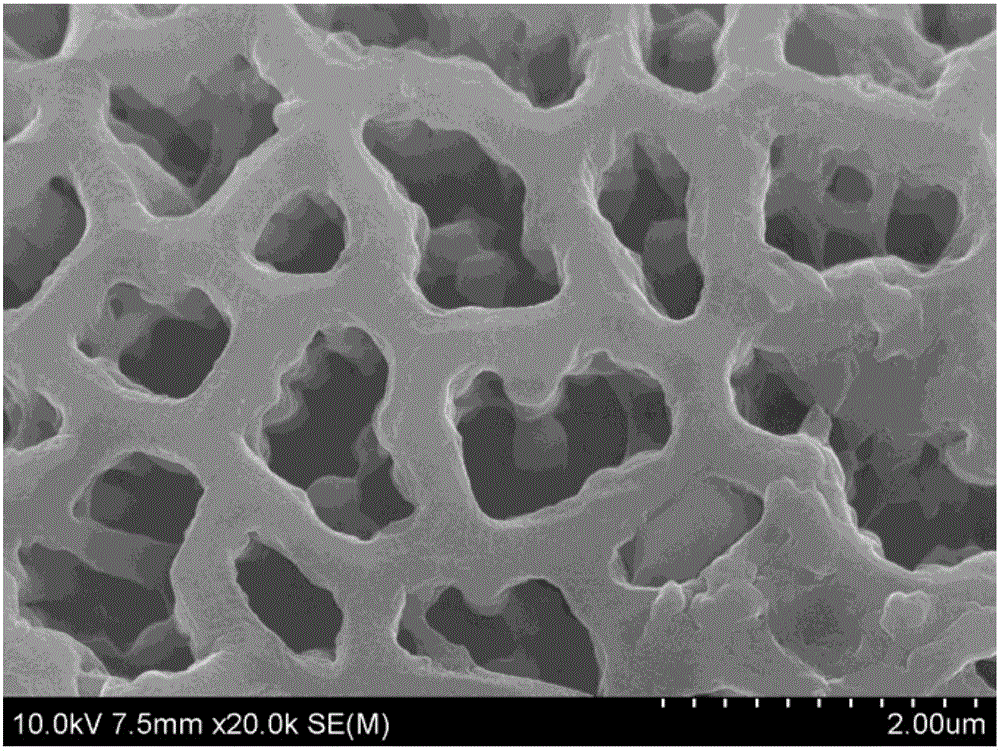

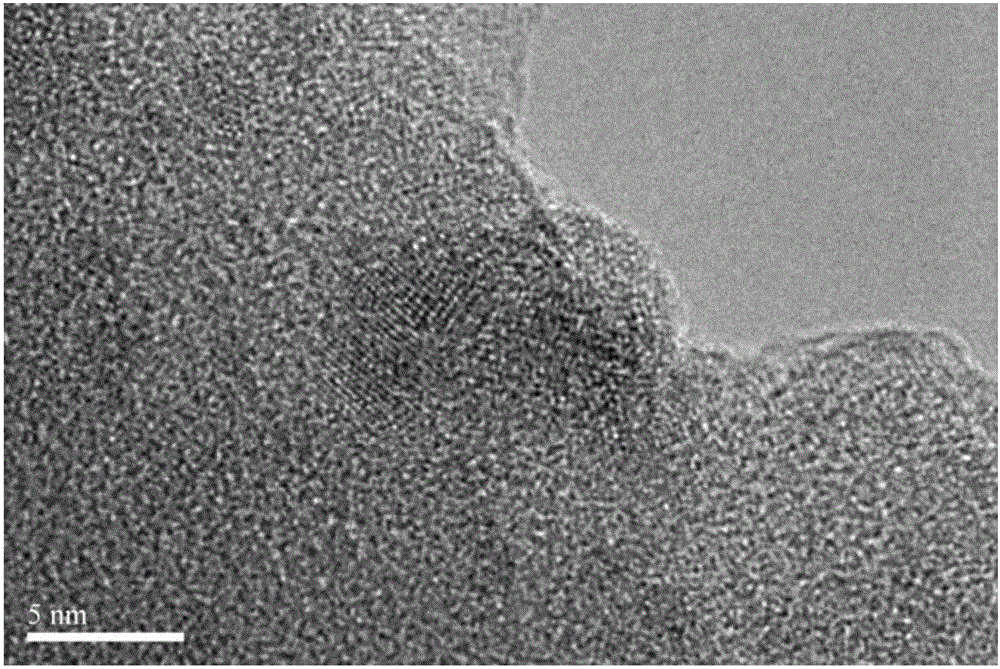

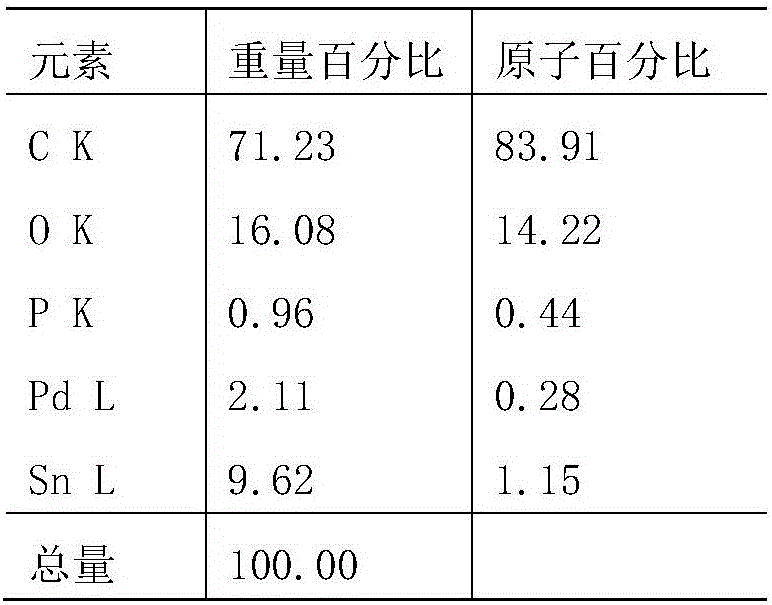

[0021] Dissolve 5g of rapeseed pollen purchased from Wang’s Honey Garden in about 100ml of absolute ethanol, wash it after ultrasonic oscillation at 40kHz for 5min, then wash it after ultrasonic oscillation at 40kHz for 25min, stir magnetically at 1000r / min at room temperature for 5min, and then suction filter , Wash, repeat this twice, and dry naturally. Take 0.05mmol PdCl 2 Dissolve the powder in 100ml of absolute ethanol to form a supersaturated solution, adjust its pH to 6, then filter with suction, and take the clear saturated solution in the upper layer as a primary impregnation solution. Immerse the pretreated pollen in the above primary dipping solution, stir it with 1000r / min magnetic force for 15h, then filter it with suction, wash it, dry it, and save it as the primary dipping product in the dark. Immerse the first impregnation product into 0.04mol / L SnCl 4 ·5H 2 O ethanol solution, magnetically stirred at 1000r / min for 8h, then suction filtered, washed, dried, p...

Embodiment 2

[0026] Dissolve 5g of rapeseed pollen purchased from Wang’s Honey Garden in about 100ml of absolute ethanol, wash it after ultrasonic oscillation at 40kHz for 5min, then wash it after ultrasonic oscillation at 40kHz for 25min, then magnetically stir at 1000r / min at room temperature for 5min and then pump Filter and wash, repeat this twice, and dry naturally. Take 0.05mmol PdCl 2 Dissolve the powder in 100ml of absolute ethanol to form a supersaturated solution, adjust its pH to 8, then filter with suction, and take the clear saturated solution in the upper layer as a primary impregnation solution. Immerse the pretreated pollen in the above primary dipping solution, stir it with 1000r / min magnetic force for 15h, then filter it with suction, wash it, dry it, and save it as the primary dipping product in the dark. Immerse the first impregnation product into 0.04mol / L SnCl 4 ·5H 2 O ethanol solution, magnetically stirred at 1000r / min for 8h, then suction filtered, washed, dried...

Embodiment 3

[0028] Dissolve 5g of rapeseed pollen purchased from Wang’s Honey Garden in about 100ml of absolute ethanol, wash it after ultrasonic oscillation at 40kHz for 5min, then wash it after ultrasonic oscillation at 40kHz for 25min, then magnetically stir at 1000r / min at room temperature for 5min and then pump Filter and wash, repeat this twice, and dry naturally. Take 0.05mmol PdCl 2Dissolve the powder in 100ml of absolute ethanol to form a supersaturated solution, adjust its pH to 8, then filter with suction, and take the clear saturated solution in the upper layer as a primary impregnation solution. Immerse the pretreated pollen in the above primary dipping solution, stir it with 1000r / min magnetic force for 15h, then filter it with suction, wash it, dry it, and save it as the primary dipping product in the dark. Immerse the first impregnation product into 0.04mol / L SnCl 4 ·5H 2 O ethanol solution, magnetically stirred at 1000r / min for 8h, then suction filtered, washed, dried,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com