Preparation method of metal monatomic site catalyst

A catalyst and atomic technology, applied in the field of catalyst material synthesis, to achieve uniform particle size distribution, low toxicity, and small product particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

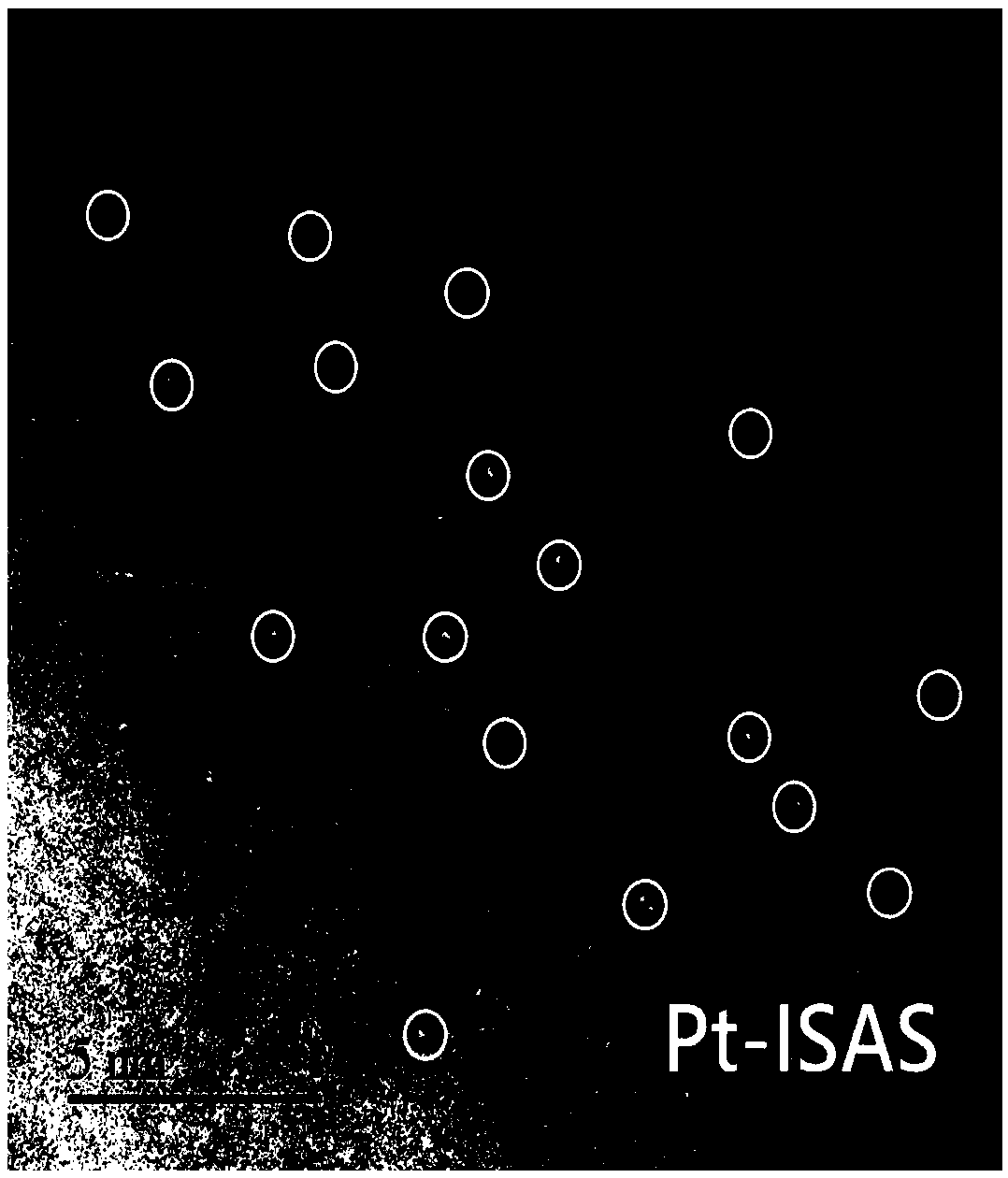

[0035] Dissolve 88 milligrams (mg) of platinum(II) acetylacetonate and 1.069 grams (g) of zinc nitrate hexahydrate in 15 milliliters (ml) of methanol, and add 1.161 grams (g) of 2-methylimidazole to 10 milliliters (ml) of methanol In the method, pour 2-methylimidazole methanol solution into the methanol solution of platinum (II) acetylacetonate and zinc nitrate hexahydrate, stir vigorously for 5 minutes, let stand for 20 hours, wash the precipitate obtained by the reaction with methanol 4 times, Dry in a vacuum oven, put the obtained powder into a magnetic boat after a little grinding, and place it in a tube furnace for heating. The heating atmosphere is nitrogen or argon. Before heating, the air in the tube furnace is replaced with an inert gas three times. The heating temperature was 900°C, the heating rate was 5°C per minute, and the heating time was 3 hours. After calcination, it was cooled to room temperature to obtain a black platinum single-atom site catalyst. Such as ...

Embodiment 2

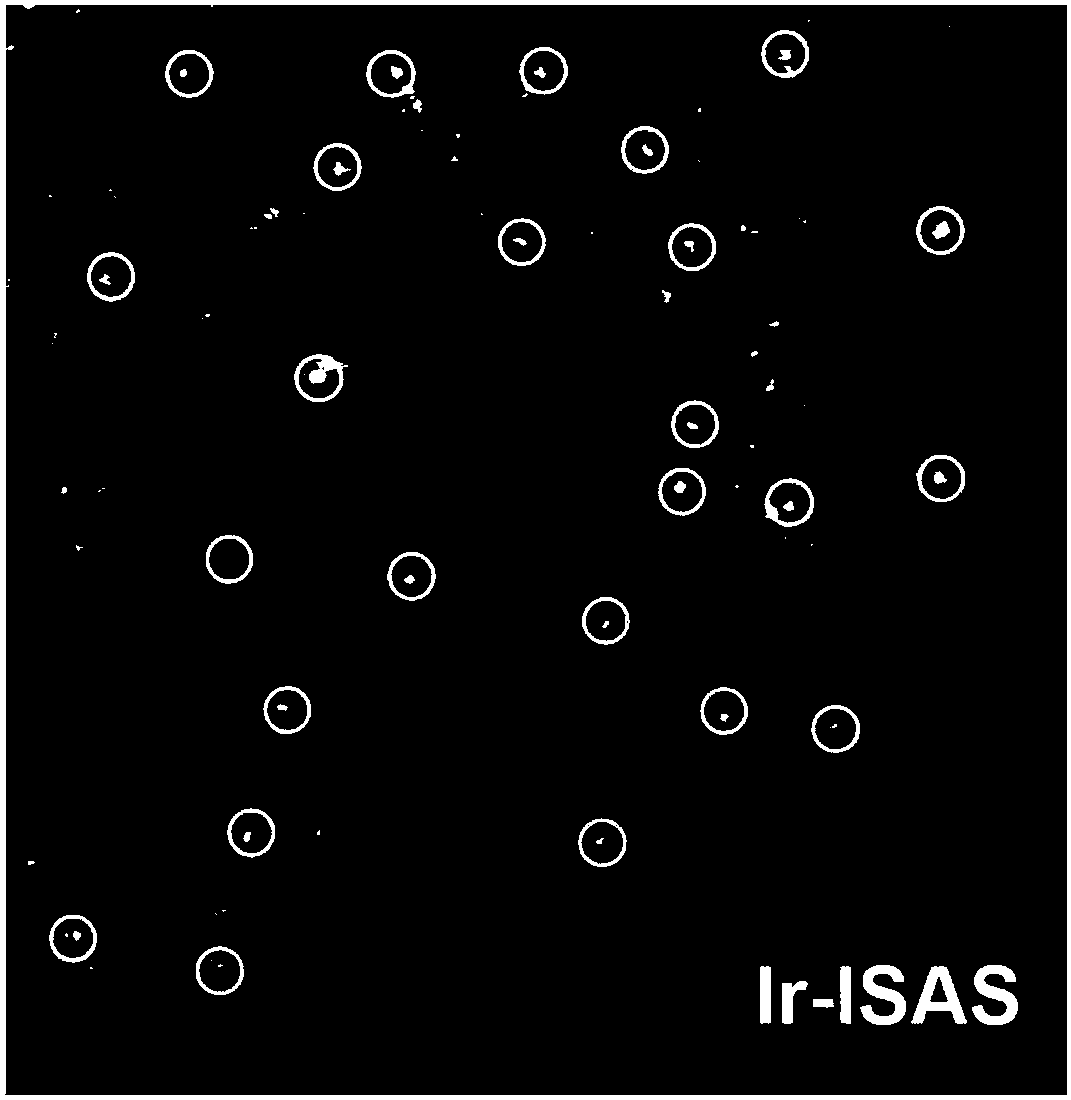

[0037] Dissolve 176mg iridium(III) acetylacetonate and 1.069g zinc nitrate hexahydrate in 15ml methanol, add 1.161g 2-methylimidazole in 10ml methanol, pour 2-methylimidazole methanol solution into iridium(III) acetylacetonate and methanol solution of zinc nitrate hexahydrate, vigorously stirred for 5 minutes, and stood still for 20 hours. The precipitate obtained from the reaction was washed 4 times with methanol, dried in a vacuum oven, and the obtained powder was slightly ground and placed in a magnetic boat. , placed in a tube furnace for heating, the heating atmosphere is nitrogen or argon, the air in the tube furnace is replaced with an inert gas three times before heating, the heating temperature is 900°C, the heating rate is 5°C per minute, and the heating time is 3 After calcination and cooling to room temperature, a black iridium single-atom site catalyst was obtained. Such as figure 2 As shown, the iridium atoms are in a monatomic dispersed state.

Embodiment 3

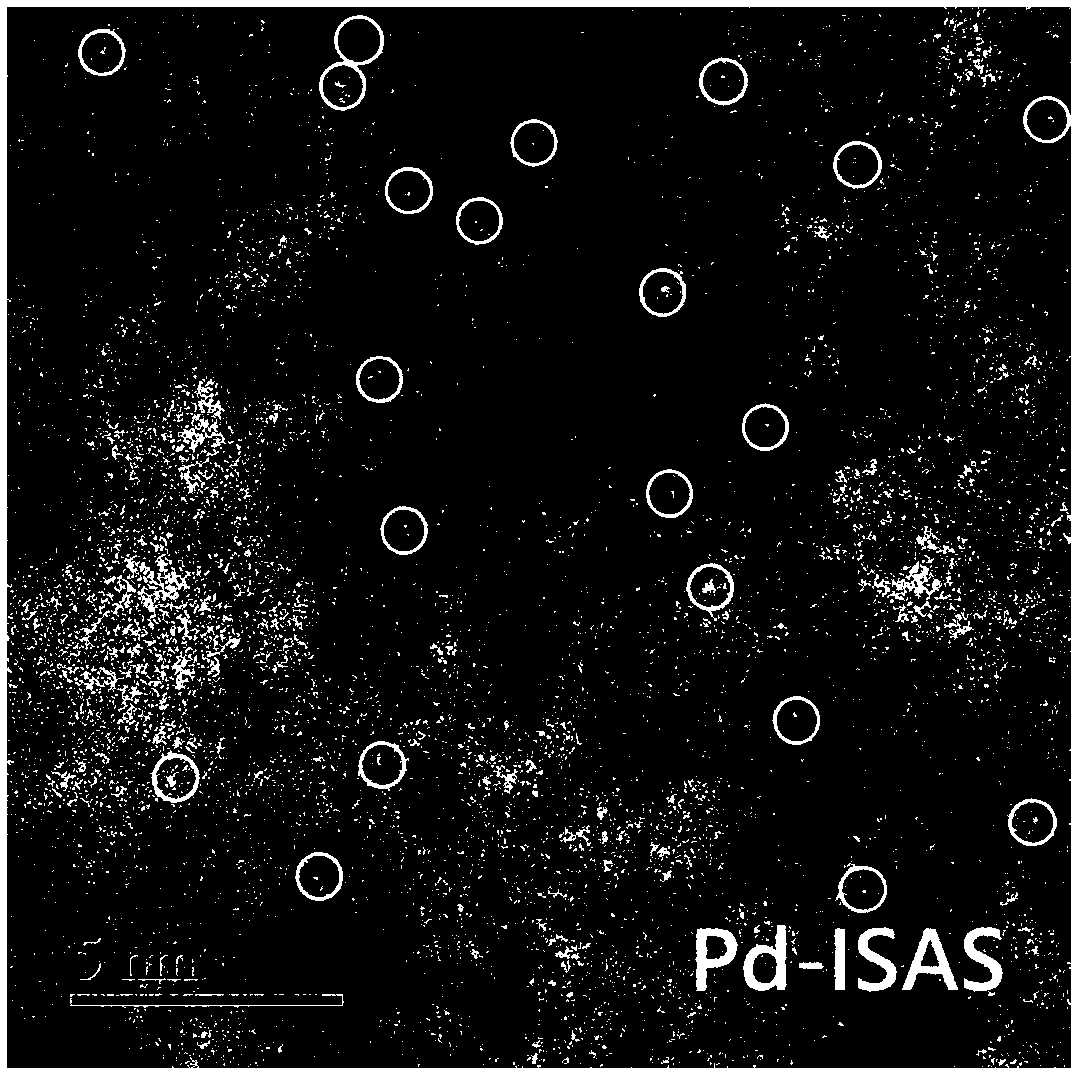

[0039]Dissolve 69mg of palladium(II) acetylacetonate and 1.069g of zinc nitrate hexahydrate in 30ml of methanol, add 1.161g of 2-methylimidazole in 10ml of methanol, pour the 2-methylimidazole methanol solution into palladium(II) acetylacetonate and methanol solution of zinc nitrate hexahydrate, vigorously stirred for 5 minutes, and stood still for 20 hours. The precipitate obtained from the reaction was washed 4 times with methanol, dried in a vacuum oven, and the obtained powder was slightly ground and placed in a magnetic boat. , placed in a tube furnace for heating, the heating atmosphere is nitrogen or argon, the air in the tube furnace is replaced with an inert gas three times before heating, the heating temperature is 800°C, the heating rate is 5°C per minute, and the heating time is 3 After calcination and cooling to room temperature, a black palladium single-atom site catalyst was obtained. Such as image 3 As shown, the palladium atoms are in single-atom dispersed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com