Preparing method for nitrogen-doped porous carbon material, catalyst comprising material and application of material

A technology of nitrogen-doped porous carbon and supported catalysts, which is applied in the direction of catalyst carriers, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of high cost and cumbersome synthesis steps of nitrogen-containing ionic liquids, and achieve uniform distribution , enhanced catalytic activity and service life, and controllable doping content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the metal-loaded catalyst of the present invention is not particularly limited, conventional deposition methods and reduction methods in the prior art can be used, for example, the prepared nitrogen-doped porous carbon material is mixed with a salt solution of a noble metal as a catalyst carrier, and the method, deposition-precipitation method, sol-gel method, and photodeposition method to load the metal on the surface of the carrier, and then use hydrogen reduction, sodium borohydride reduction, hydrazine hydrate reduction, sodium formate reduction, formaldehyde reduction, sodium citrate Any one of the reduction, ascorbic acid reduction, ethylene glycol reduction, ethanol reduction and methanol reduction methods can be used to reduce the metal atoms, and finally a nitrogen-doped porous carbon-supported noble metal catalyst can be obtained.

[0037] The specific surface area of the final nitrogen-doped porous carbon material obtained according...

preparation Embodiment 1

[0045] Preparation Example 1: Preparation of nitrogen-doped porous carbon material

[0046] Dissolve 0.5g of dicyandiamide, 9g of glucose and 0.75g of sodium tetraborate in 20mL of deionized water, transfer it to the reaction kettle after mixing evenly, keep it at 180°C for 24 hours, after cooling, filter, wash, and dry to obtain Reddish-brown solid. Afterwards, the obtained reddish-brown solid was calcined in a tube furnace in an argon gas atmosphere, and kept at 550° C. for 24 hours. After the tube furnace dropped to room temperature, the sample was taken out and ground to obtain a nitrogen-doped porous carbon material.

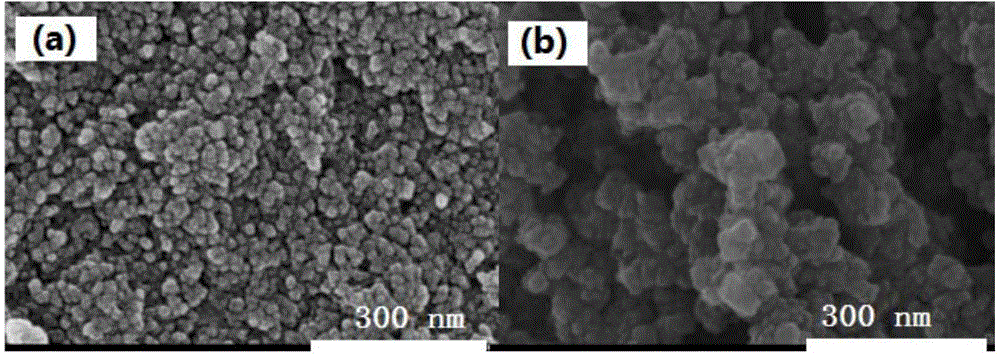

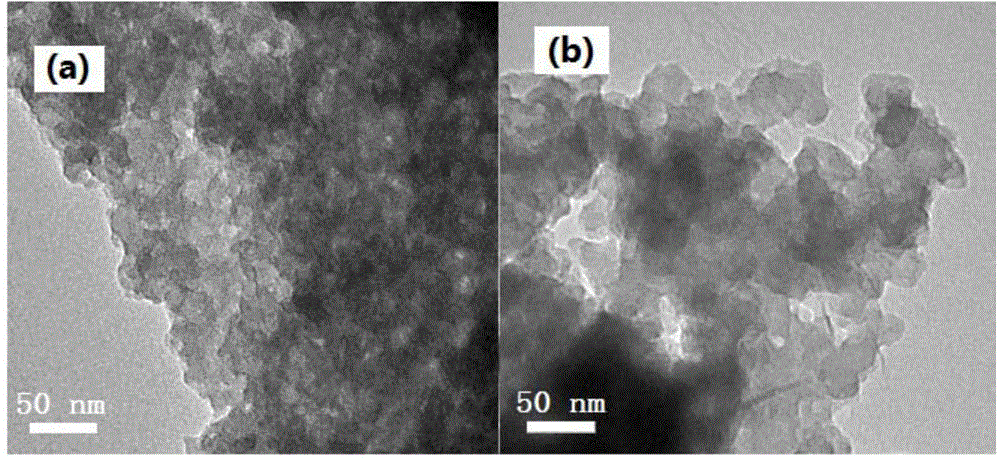

[0047] figure 1 (b) and figure 2 (b) are the SEM and TEM photos of the nitrogen-doped porous carbon material prepared according to this preparation example. It can be seen from the photos that when an appropriate amount of nitrogen-containing substance is added, a clear porous network structure can be seen.

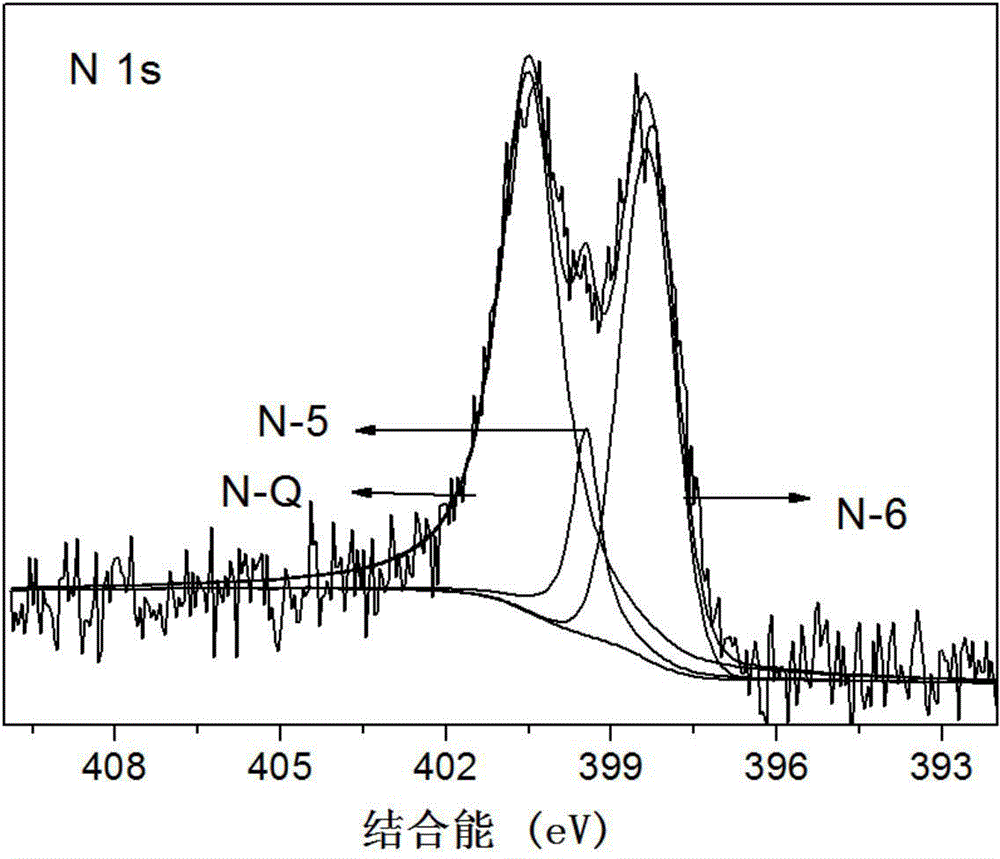

[0048] XPS elemental analysis results ( i...

preparation Embodiment 2

[0051] The amount of dicyandiamide was changed to 0.1 g, and the nitrogen-doped carbon material was prepared according to the same method as in Example 1. The elemental analysis results show that the nitrogen content of the material is 2.8at%, and the BET test results show that the specific surface area is about 580m 2 / g, the material is a micro-mesoporous structure, but compared with the material obtained in Preparation Example 1, the particles are smaller, and the result is obtained by Figure 5 shown in the TEM photographs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com