Nano composite material of graphene/nylon/elastomer and preparation method thereof

A nanocomposite material and graphene technology, which is applied in the field of polymers, can solve the problems of ignoring the comprehensive performance of nylon materials and not being suitable for commercial production, and achieve the effects of improved strength and toughness, low cost, and fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

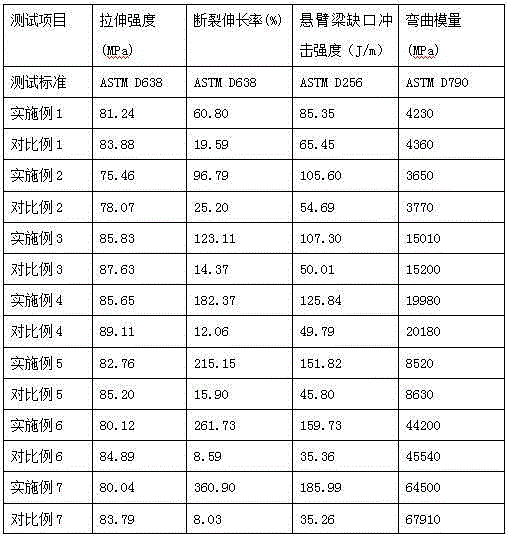

Examples

Embodiment 1

[0048] (1) Put 1000 parts of caprolactam into the flask to heat and melt, then add 0.1 part of single-layer graphene, and use strong ultrasound for 5 minutes to obtain a mixed melt;

[0049] (2) Add 1 part of alkaline earth metal and 0.1 part of 2,4 toluene diisocyanate into the mixed melt, and shake to obtain a blend;

[0050] (3) Put the blend liquid into the feeding tank of the extruder, start the machine, adjust the flow rate of the feeding tank, react and extrude at a uniform speed, and then granulate after cooling in a cold water bath to obtain the masterbatch of graphene / nylon composite material;

[0051] (4) Melt, blend and extrude the masterbatch obtained above with 1 part of polyurethane elastomer, and add 0.5 parts of cyclic anhydride compatibilizer and 5 parts of plasticizer at the same time, and the extruded material is passed through cold water After the bath is cooled, it is sent to a cutting machine for cutting and pelletizing to obtain a graphene / nylon / elastom...

Embodiment 2

[0053] (1) Put 1000 parts of caprolactam into the flask to heat and melt, then add 1 part of double-layer graphene, and use strong ultrasound for 10 minutes to obtain a mixed melt;

[0054] (2) Add 10 parts of sodium hydroxide and 1 part of N-acetylcaprolactam into the mixed melt, and shake to obtain a blend;

[0055] (3) Put the blend liquid into the feeding tank of the extruder, start the machine, adjust the flow rate of the feeding tank, react and extrude at a uniform speed, and granulate after cooling in a cold water bath to obtain the masterbatch of graphene / nylon composite material;

[0056] (4) Melt, blend and extrude the masterbatch obtained above with 10 parts of polyolefin elastomer, and add 1 part of carboxylic acid type compatibilizer and 10 parts of antioxidant at the same time, and the extruded material is passed through cold water After the bath is cooled, it is sent to a cutting machine for cutting and pelletizing to obtain a graphene / nylon / elastomer nanocompos...

Embodiment 3

[0058] (1) Put 1000 parts of caprolactam into the flask to heat and melt, then add 100 parts of few-layer graphene, and use strong ultrasound for 20 minutes to obtain a mixed melt;

[0059] (2) Add 30 parts of sodium caprolactam and 10 parts of N-benzoyl caprolactam into the mixed melt, and shake to obtain a blend;

[0060] (3) Put the blend liquid into the feeding tank of the extruder, start the machine, adjust the flow rate of the feeding tank, react and extrude at a uniform speed, and granulate after cooling in a cold water bath to obtain the masterbatch of graphene / nylon composite material;

[0061] (4) Melt, blend and extrude the masterbatch obtained above with 100 parts of polyamide elastomer, and add 5 parts of epoxy compatibilizer and 20 parts of light stabilizer at the same time, and the extruded material is passed through cold water After the bath is cooled, it is sent to a cutting machine for cutting and pelletizing to obtain a graphene / nylon / elastomer nanocomposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com