Composite nanoparticle with calcium fluoride coated with aluminum oxide and preparation method thereof

A technology for compounding nanoparticles and coating calcium fluoride, which is applied in the field of coating and modifying the surface of nano-materials, can solve the problems of limited application of nano-calcium fluoride, and achieves good coating effect, low cost and uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

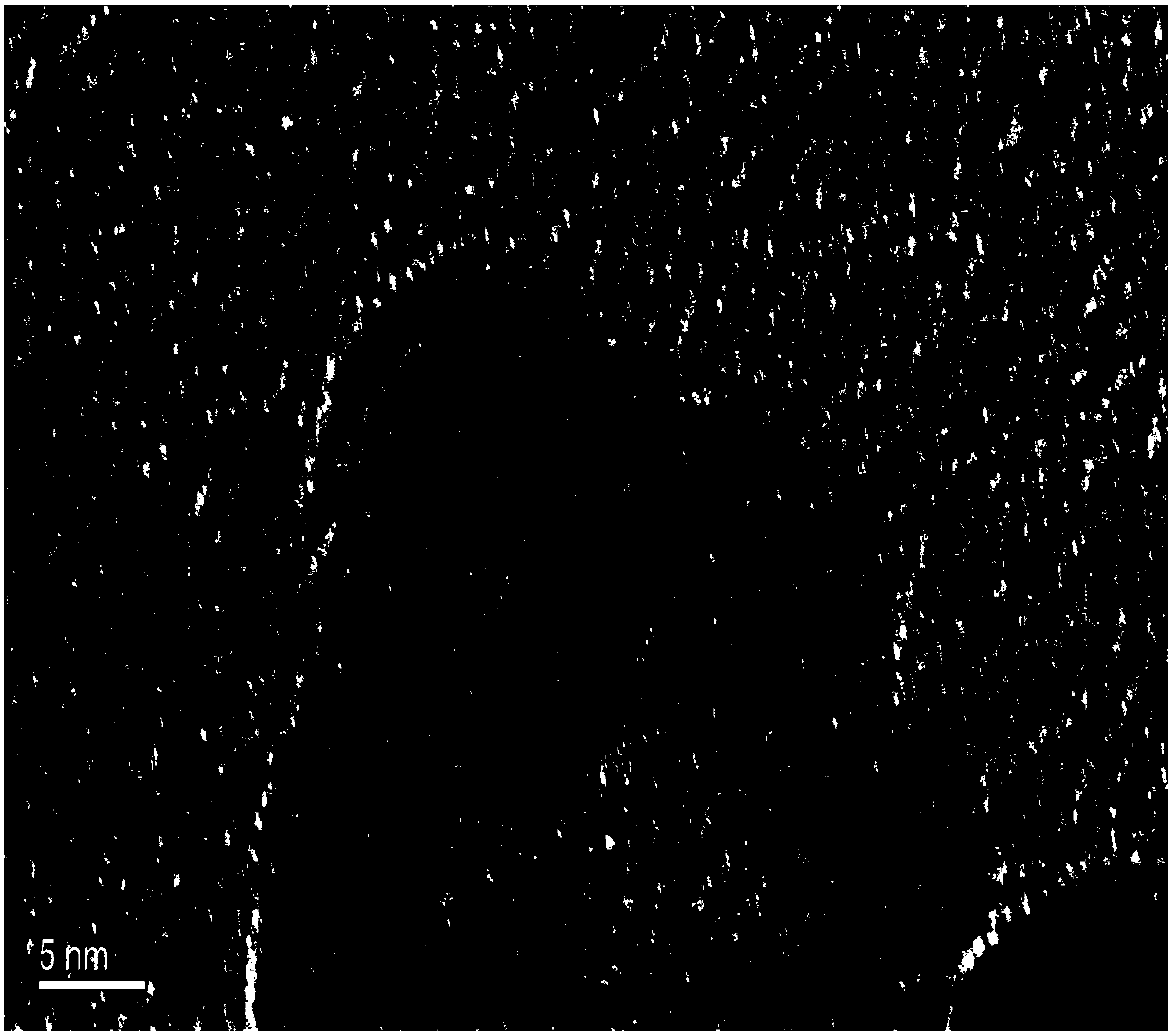

Image

Examples

Embodiment 1

[0041]Weigh 100ml of ammonia water and ethanol solution in a volume ratio of 1:4, put the two in a beaker and mix them evenly to obtain solution A. According to the volume ratio of 1:4, weigh a total of 150ml of xylene solution and ethanol solution, and place them in two beakers for later use. Take an appropriate amount of polyvinylpyrrolidone (PVP) and add it to the ethanol solution, ultrasonically disperse and mechanically stir for 20 minutes, so that the concentration of PVP contained in the solution is 5g / L, and an ethanol solution containing polyvinylpyrrolidone is obtained. Take the xylene solution, add it into the ethanol solution under stirring condition, make it mix evenly, and divide it into two parts according to the volume ratio of 2:1, and obtain two solutions of B and C. Weigh 0.01 mol of calcium fluoride material, add it into solution B under ultrasonic and stirring conditions, and continue ultrasonic stirring for 30 minutes. Dissolve 0.03 mol of aluminum nitra...

Embodiment 2

[0045] Weigh 100ml of ammonia water and ethanol solution in a volume ratio of 1:4, put the two in a beaker and mix them evenly to obtain solution A. Take by weighing ethanol solution 150ml, take appropriate amount of polyvinylpyrrolidone (PVP) and join ethanol solution, ultrasonic dispersion and mechanical stirring 20min, the concentration of PVP contained in the preparation solution is 5g / L, must contain the ethanol solution of polyvinylpyrrolidone, and by volume The ratio of 2:1 is divided into two parts, and two solutions of B and C are obtained. Weigh 0.01 mol of calcium fluoride material, add it into solution B under ultrasonic and stirring conditions, and continue ultrasonic stirring for 30 minutes. Dissolve 0.03 mol of aluminum nitrate solid material in 10 ml of distilled water, add it into solution C under stirring condition, and continue ultrasonic stirring for 5-10 minutes. Mix solution B and solution C under ultrasonic and stirring conditions to obtain solution D, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com