Preparation method of modified magnetic composite nano particles and application thereof in pesticide detection

A magnetic composite nanometer and composite nanoparticle technology, applied in the fields of food safety testing and nanomaterial technology, can solve the problems such as the inability of the nanocomposite substrate to meet the detection limit requirements, and achieve the improvement of SERS detection sensitivity and specificity, consistent particle morphology, The effect of shortening the detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

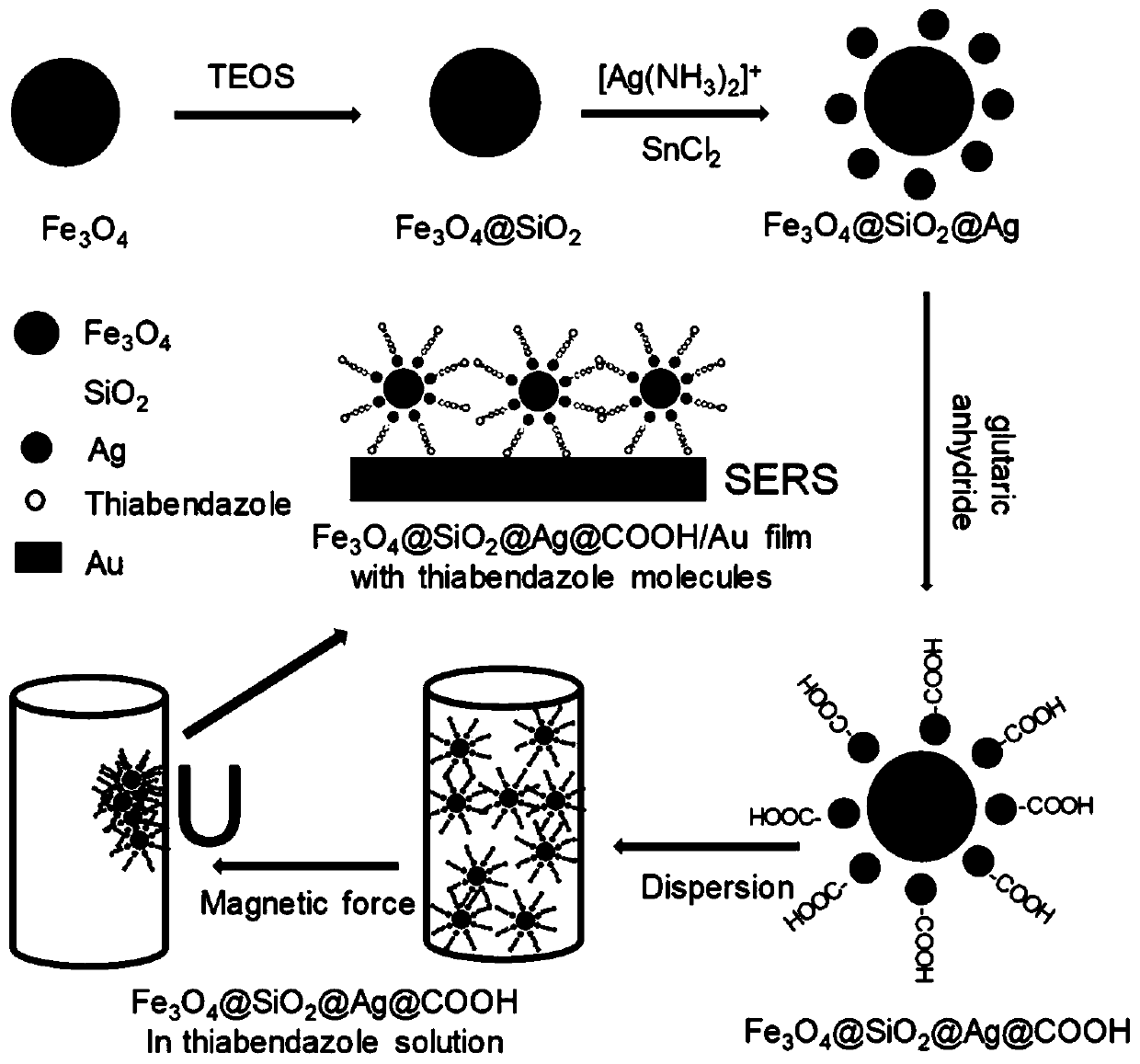

[0038] Example 1 Magnetic Fe 3 o 4 Preparation of NPs

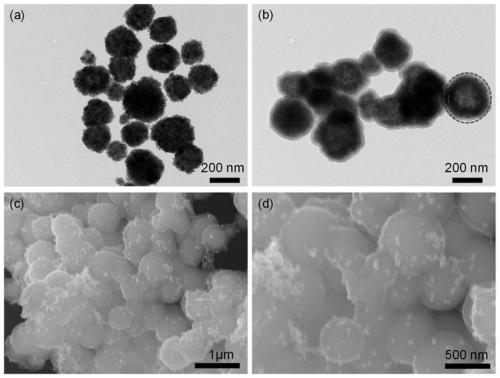

[0039] Synthesized by solvothermal synthesis, 8.1 g of FeCl 3 ·6H 2 O was added to 70ml of ethylene glycol, mixed and stirred at 60°C for 10min, and then 7.2g of NaAc·3H was added to the above solution 2 O and 2.0 g of sodium citrate, stirred vigorously at 60°C for 30min, transferred to a polytetrafluoroethylene-lined stainless steel reaction kettle, sealed and placed in an electric blast drying oven at 200°C for 10h; after natural cooling, magnetic collection , washed three times with ethanol, and the precipitate was dried for later use; see figure 2 (a), These rough-surfaced spherical Fe3O4 nanoparticles have uniformly distributed sizes with an average diameter of about 300 nm.

Embodiment 2

[0040] Example 2 Fe 3 o 4 @SiO 2 Preparation of NPs

[0041] Fe 3 o 4 Nanoparticles (0.1g) were added containing 10ml water, 180ml ethanol and 8ml NH 3 ·H 2 O mixture solution, after 30 minutes of ultrasonic treatment, so that it is well dispersed in the solution. Then, slowly add 0.8ml TEOS to the above solution and stir; after reacting for 2 hours, collect again by magnetic force and wash with ethanol and deionized water. Finally, dry at 60°C for later use; see figure 2 (b), the average diameter increased to 330nm, and the spherical structure remained unchanged, proving that SiO 2 shell in Fe 3 o 4 The coating on NPs is uniform. with Fe 3 o 4 NPs compared to SiO 2 The surface is smooth and the transparency is higher, which is also SiO 2 Features of the enclosure. Therefore, the core-shell structure can be observed, and the changes in their surface morphology and particle size are obvious, indicating that the synthesis of different products at each step is s...

Embodiment 3

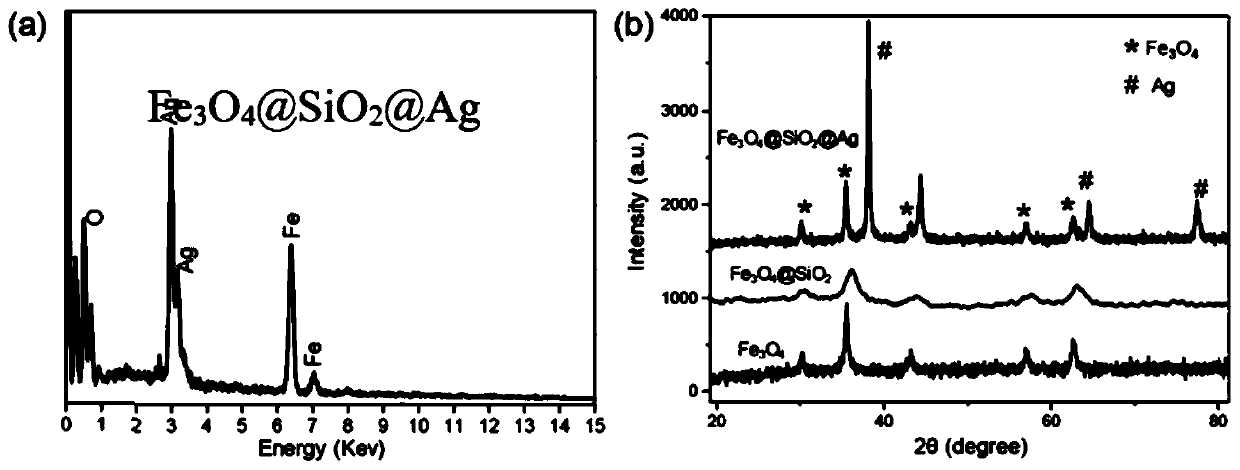

[0042] Example 3 Fe 3 o4 @SiO 2 Preparation of @Ag NPs

[0043] 0.1g of Fe 3 o 4 @SiO 2 Nanoparticles were dispersed in 15ml of ethanol by ultrasonication for 5min, and then 5ml of HCl with a volume concentration of 5% and 10ml of SnCl with a concentration of 10g / L were added to the above solution 2 , 20min sonication. Then, the obtained composite nanoparticles were separated from the solution by magnetic force, and then quickly rinsed three times with deionized water; then 10 ml of PVP aqueous solution with a concentration of 2 g / L was added to fresh [Ag(NH 3 ) 2 ] + solution, where fresh [Ag(NH 3 ) 2 ] + The solution consists of 5ml of AgNO with a concentration of 12g / L 3 The solution was added with 25ml of NH 3 ·H 2 O is prepared; the composite nanoparticles obtained by step (2) are redispersed in the above-mentioned mixed solution; adding 12ml concentration is 12g / L glucose and 3ml concentration is the sodium tartrate reducing solution of 5g / L, stirring at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com