A method for mass-preparing platinum-based dealloyed electrocatalysts for fuel cell cathodes

A fuel cell cathode and alloy catalyst technology, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as increased production costs and complicated operations, and achieve the effects of reducing platinum loss, increasing specific activity, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

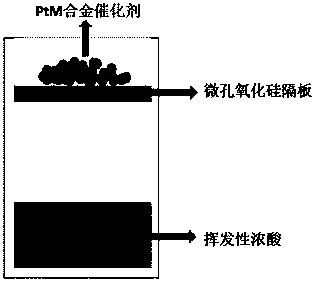

[0017] (1) Get 1g Pt1Ni1 / C commercial catalyst (purchased from Premetek company) and place as figure 1 The microporous silica plate of the device shown has a pore diameter of 0.05-0.1 μm and a plate thickness of 0.3 cm. 3 Inside the hydrothermal reactor, microporous silica plate and concentrated HNO 3 The liquid surface distance is 10 cm, and the lid is tightly closed; the hydrothermal reaction kettle is put into an oven, the set temperature is kept at 80°C, and the reaction time is 3 hours;

[0018] (2) After the reaction is completed, remove the reactor from the oven and cool to room temperature, pour out the concentrated HNO at the bottom of the reactor 3 , and add 20mL of deionized water, so that the distance between the liquid surface of deionized water and the microporous silicon oxide plate is 10 cm, close the lid tightly, put it into the oven, set the temperature at 110°C, and last for 2 hours; follow the above operation to use Ionized water thoroughly cleaned the pr...

Embodiment 2

[0022] (1) Weigh 80mg of XC-72R carbon black into a four-necked bottle, add 40ml of ethylene glycol (EG) and sonicate for 1 hour; mix well and add 50mg of CuSO 4 ·5H 2 O, 38 mg H 2 PtCl 6 ·6H 2 Dilute with 0 and 20ml EG, stir magnetically for 1 hour to fully dissolve the solid; adjust the pH of the above solution to 10.0 with 1mol / L KOH / EG solution, and stabilize it for 30 minutes; then transfer the above mixed solution to a microwave reactor, and pass N 2 10min to remove the air in the solution, set the microwave power to 600W, heat at 190°C for 10min; after cooling to room temperature, centrifuge and wash until free of Cl - In the presence of other heteroions, freeze-dry for 12 hours, the resulting solid is the Pt1Cu1 / C alloy catalyst;

[0023] (2) get the Pt1Cu1 / C catalyst synthesized in 1g step (1) and place it in such as figure 1 The microporous silica plate of the device shown has a pore diameter of 0.05-0.1 μm and a plate thickness of 0.3 cm, and then the device i...

Embodiment 3

[0027] (1) Weigh 80mg of XC-72R carbon black into a four-necked bottle, add 40ml of ethylene glycol (EG) and sonicate for 1 hour; mix well and add 50mg of CoCl respectively 2 ·6H 2 O, 38 mg H 2 PtCl 6 ·6H 2 Dilute with 0 and 20ml EG, stir magnetically for 1 hour to fully dissolve the solid; adjust the pH of the above solution to 10.0 with 1mol / L KOH / EG solution, and stabilize it for 30 minutes; then transfer the above mixed solution to a microwave reactor, and pass N 2 10min to remove the air in the solution, set the microwave power to 600W, heat at 190°C for 10min; after cooling to room temperature, centrifuge and wash until free of Cl - In the presence of other hetero ions, freeze-dry for 12 hours, and the resulting solid is the Pt1Co1 / C alloy catalyst.

[0028] (2) Get the Pt1Co1 / C catalyst synthesized in 1g step (1) and place it as figure 1The microporous silica plate of the device shown has a pore diameter of 0.05-0.1 μm and a plate thickness of 0.3 cm. 3 Inside th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com