Method of lithium vanadium phosphate-coated ternary material of lithium ion battery

A ternary material, lithium vanadium phosphate technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of poor rate performance and cycle performance of ternary materials, so as to improve large rate performance, improve rate performance and cycle performance , good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

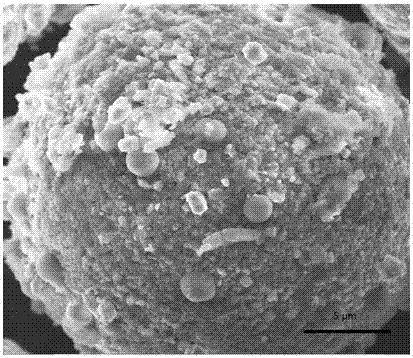

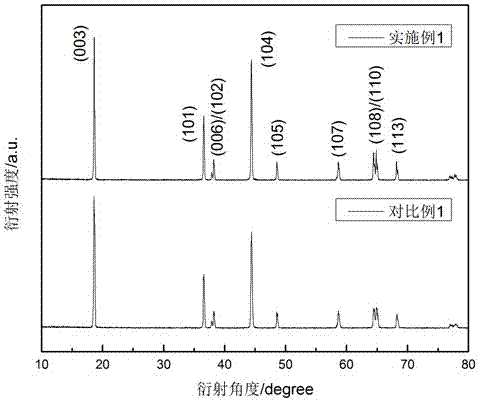

Embodiment 1

[0035] (1) Accurately weigh 10g Ni 0.8 co 0.15 al 0.05 (OH) 2 The ternary material precursor and 4.84g of lithium hydroxide monohydrate (the molar ratio of the metal element in the ternary material precursor to the lithium element in the lithium source is =1:1.05), grind for 1 hour and mix evenly, put it into a tubular resistance furnace In an oxygen atmosphere, at a heating rate of 5°C / min, pre-sintering at 450°C for 6h, calcining at 750°C for 12h, and grinding for 1h after cooling, the particle size after grinding is 8-12 microns, to obtain LiNi 0.8 co 0.15 al 0.05 o 2 Ternary materials, put them in the oven for later use;

[0036] (2) Accurately weigh 0.0272g lithium carbonate, 0.0574g ammonium metavanadate, 0.0846g ammonium dihydrogen phosphate, 0.0927g dihydrate oxalic acid (carbon source), control the lithium element in the lithium source, the vanadium element in the vanadium source, The molar ratio of the phosphorus element in the phosphorus source to the carbon ...

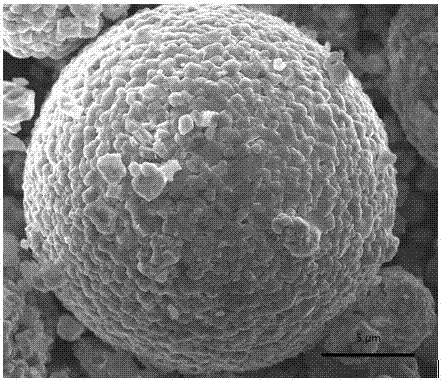

Embodiment 2

[0041] (1) Accurately weigh 10g Ni 0.6 co 0.2 mn 0.2 (OH) 2 The ternary material precursor and 4.69g lithium carbonate (the molar ratio of the metal element in the ternary material precursor to the lithium element in the lithium source is =1:1.05), gently grind for 1h and mix well, put it into a tube resistance furnace , in an oxygen atmosphere at a heating rate of 5°C / min, pre-sintered at 550°C for 6h, sintered at 800°C for 15h, ground after cooling, the particle size after grinding is 8-12 microns, and the grinding time is 1h; LiNi 0.6 co 0.2 mn 0.2 o 2 Ternary materials, put them in the oven for later use;

[0042] (2) Accurately weigh 0.0375g of lithium acetate dihydrate, 0.0287g of ammonium metavanadate, 0.0423g of ammonium dihydrogen phosphate, 0.0589g of citric acid, and 0.0066g of glucose (both citric acid and glucose are carbon sources). The molar ratio of lithium element, vanadium element in vanadium source, phosphorus element in phosphorus source, and carbon ...

Embodiment 3

[0046] (1) Accurately weigh 10g Ni 0.8 co 0.15 Al 0.05 (OH) 2 The ternary material precursor and 4.84g of lithium hydroxide monohydrate (the molar ratio of the metal element in the ternary material precursor to the lithium element in the lithium source is =1:1.05), grind for 1 hour and mix evenly, put it into a tubular resistance furnace In an oxygen atmosphere, at a heating rate of 5°C / min, pre-sintering at 500°C for 6 hours, sintering at 750°C for 15 hours, and grinding after cooling. The particle size after grinding is 8-12 microns, and the grinding time is 1h. get LiNi 0.8 co 0.15 Al 0.05 o 2 Ternary materials, put them in the oven for later use;

[0047] (2) Accurately weigh 0.7507g lithium acetate dihydrate, 0.4462g vanadium pentoxide, 0.8460g ammonium dihydrogen phosphate, 0.8658g oxalic acid dihydrate, 0.1414g citric acid (both oxalic acid and citric acid are carbon sources), and control lithium The molar ratio of lithium in the source, vanadium in the vanadium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com