Nanocomposite particles and preparation method thereof

A nanocomposite and nanoparticle technology, applied in the field of materials science, can solve the problems of poor water solubility of porphyrin molecules, low PDT effect, easy agglomeration, etc., and achieve good photothermal effect, good photothermal effect, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

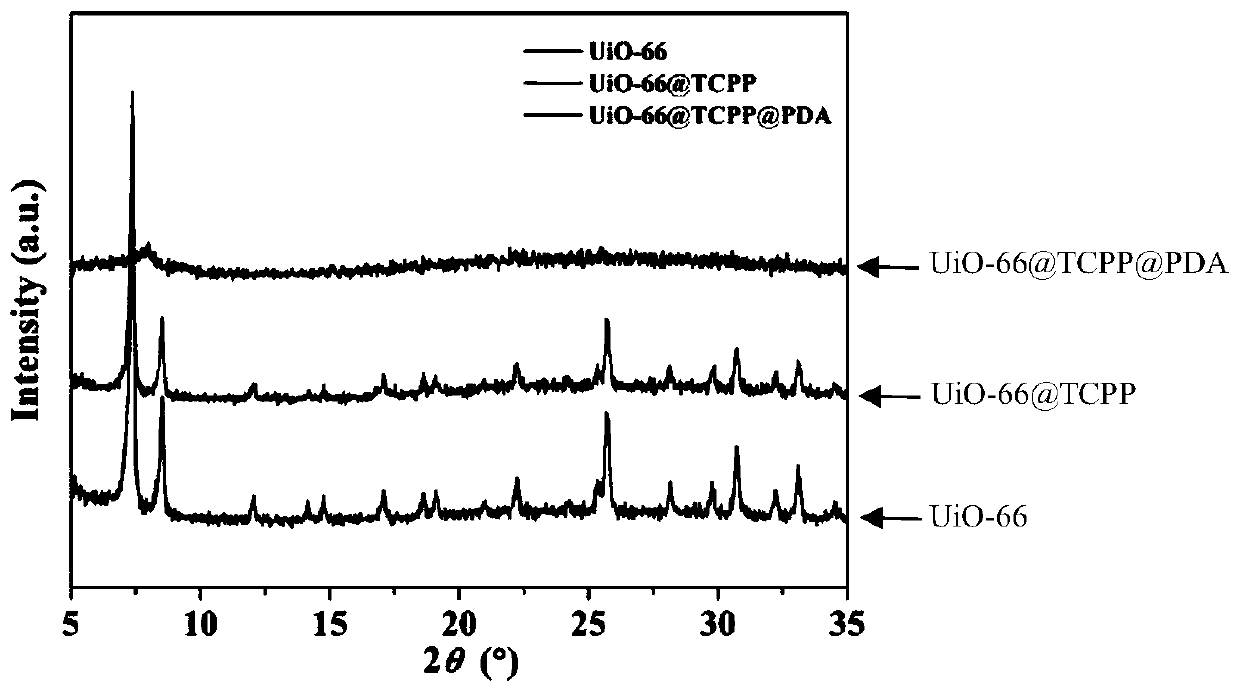

[0036] The preparation method of the nanocomposite particles provided by the invention is as follows:

[0037]Step one, ZrCl 4 Soluble in N,N-dimethylformamide to form ZrCl 4 solution, then in ZrCl 4 Terephthalic acid, benzoic acid, hydrochloric acid and meso-tetrakis(4-carboxyphenyl)porphine were sequentially added into the solution to obtain a green solution after dissolution;

[0038] Step 2, transfer the green solution to a hydrothermal kettle, react at 100-150°C for 12-48 hours, then cool at room temperature to obtain the first suspension;

[0039] Step 3, centrifuging the first suspension to obtain a purple precipitate, washing the purple precipitate with the first solvent, and vacuum-drying the cleaned purple precipitate to obtain the embedded medium-tetrakis (4-carboxyphenyl) porphyrin phenometallic organic framework nanoparticles;

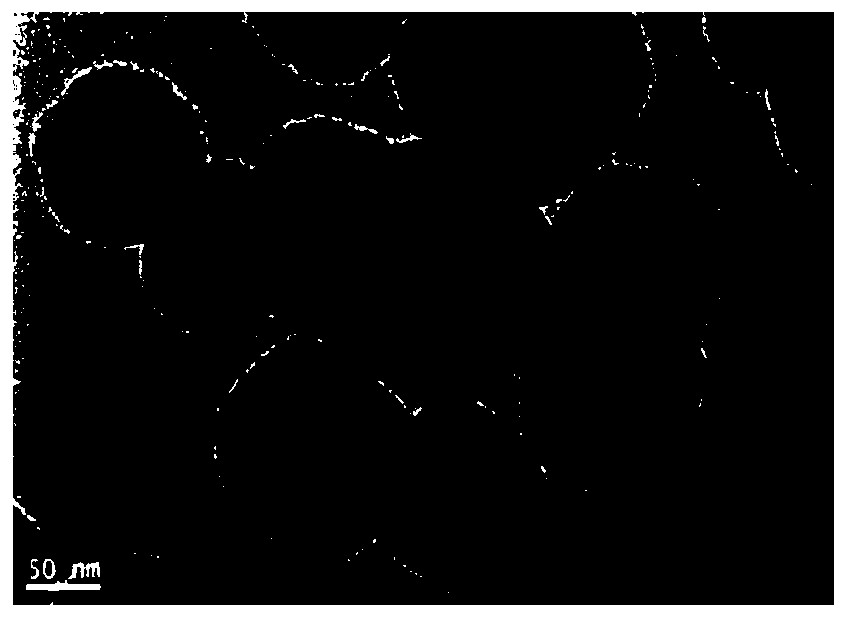

[0040] Step 4, adding metal-organic framework nanoparticles to a buffer solution with pH>7, then adding a predetermined amount of dop...

Embodiment 1

[0043] Embodiment 1 is the preparation experiment of the nanocomposite particle of the present invention, comprises the following steps:

[0044] Step 1, 0.3mmol ZrCl 4 Dissolve in 6ml N,N-dimethylformamide to form ZrCl 4 solution, then in ZrCl 4 Add 0.3mmol terephthalic acid, 5mmol benzoic acid, 1.5mmol hydrochloric acid and 0.015mmol meso-tetrakis(4-carboxyphenyl)porphine (TCPP) to the solution in sequence, and sonicate for 10min until completely dissolved, and a green solution is obtained after dissolution.

[0045] Step 2: transfer the green solution to a hydrothermal kettle (polytetrafluoroethylene lined, stainless steel kettle body), perform solvothermal reaction at 120° C. for 24 hours, and then cool to room temperature to obtain the first suspension.

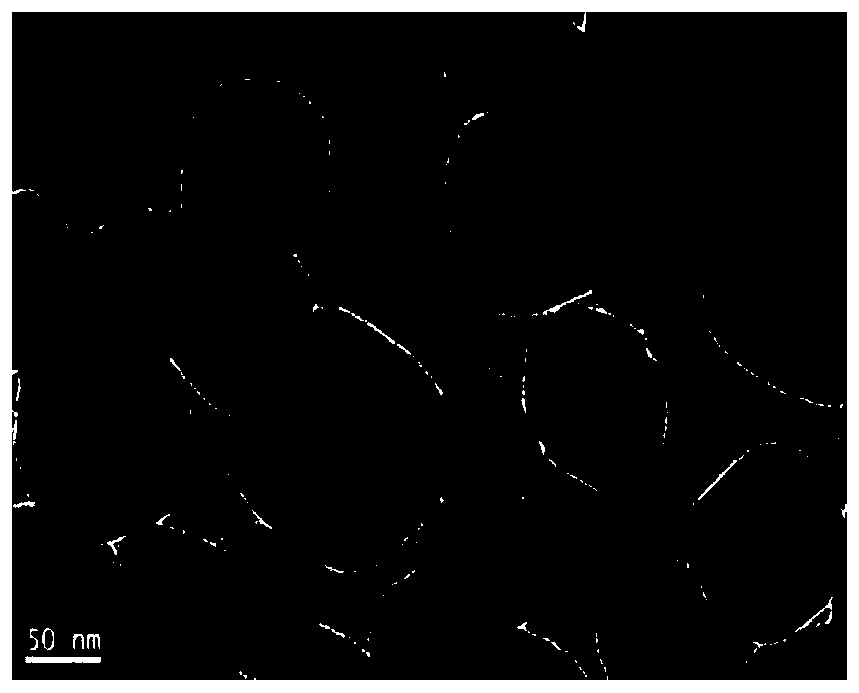

[0046] Step 3: Centrifuge the first suspension at 10,000 rpm to obtain a purple precipitate, wash the purple precipitate with N,N-dimethylformamide, ethanol, and deionized water three times, and then place the purple p...

Embodiment 2

[0068]Embodiment 2 is the preparation experiment of the nanocomposite particle of the present invention, comprises the following steps:

[0069] Step 1, 0.3mmol ZrCl 4 Dissolve in 6ml N,N-dimethylformamide to form ZrCl 4 solution, then in ZrCl 4 Add 0.3mmol terephthalic acid, 9mmol benzoic acid, 1.5mmol hydrochloric acid and 0.015mmol meso-tetrakis(4-carboxyphenyl)porphine (TCPP) successively to the solution, and ultrasonically for 10min until it is completely dissolved, and a green solution is obtained after dissolution.

[0070] Step 2: transfer the green solution to a hydrothermal kettle (polytetrafluoroethylene lined, stainless steel kettle body), perform solvothermal reaction at 130° C. for 12 hours, and then cool to room temperature to obtain the first suspension.

[0071] Step 3, centrifuge the first suspension at 8000rpm to obtain a purple precipitate, wash the purple precipitate with ethanol three times, and then place the purple precipitate in a vacuum drying oven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com