Green synthesis method of epoxy modified starch-based emulsion

A technology of epoxy modification and green synthesis, applied in the field of materials, to achieve the effect of improved performance, good monodispersity and clean surface

- Summary

- Abstract

- Description

- Claims

- Application Information

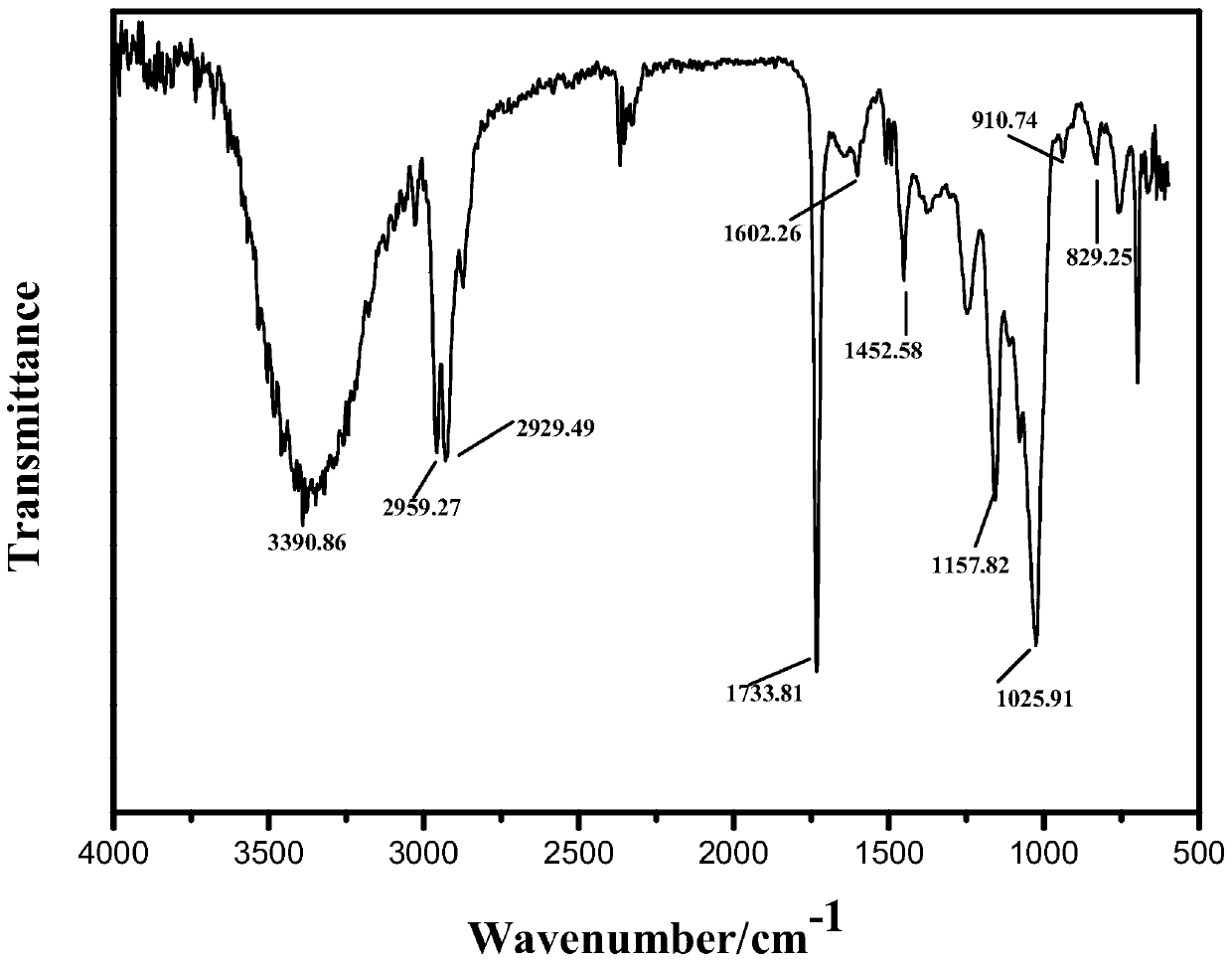

AI Technical Summary

Problems solved by technology

Method used

Image

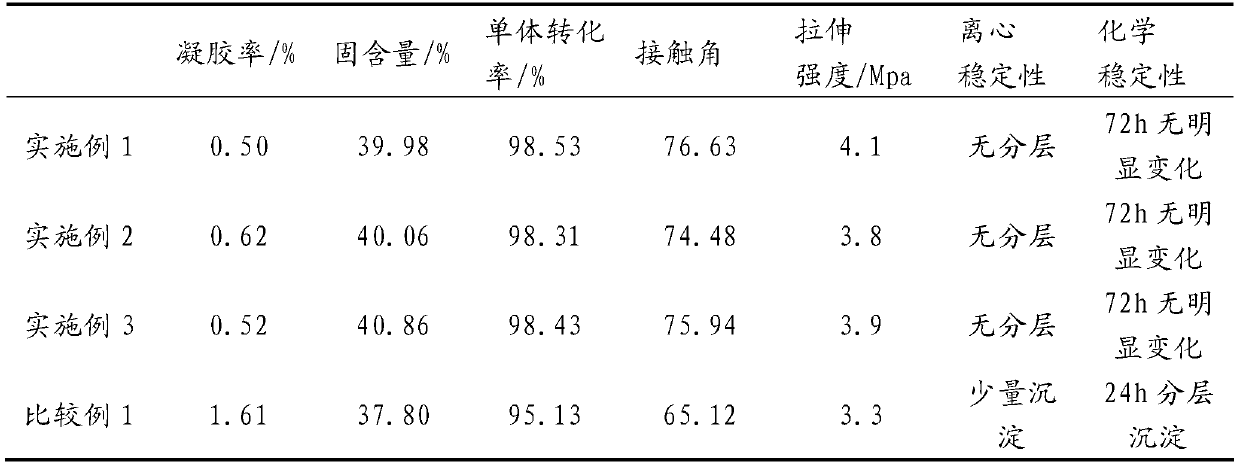

Examples

Embodiment 1

[0028] A green synthesis method of epoxy-modified starch-based emulsion, the content of each component in the formula is calculated by mass, and the unit is gram:

[0029] Starch: 30g

[0030] Hydrogen peroxide: 11.25g

[0031] Butyl acrylate: 22.5g

[0032] Styrene: 18g

[0033] Epoxy resin E-44: 4.5g

[0034] Water 100g

[0035] Synthesis:

[0036] 1) Take the components according to the above-mentioned weight parts and set aside;

[0037] 2) First mix the starch and water uniformly and then add it to a four-necked flask, add 4.5g of catalyst hydrogen peroxide, heat to 45-90°C, and control the reaction time within 1-1.5h to obtain a gelatinized liquid with dispersion stability;

[0038] 3) Add butyl acrylate and 3.375g initiator hydrogen peroxide dropwise to the gelatinization solution at the same time, control the temperature at 80°C, dropwise time 60-80min, dropwise finish the heat preservation reaction 0.5-1.0h, prepare the nuclear layer polymerization Substance emulsion

[0039] 4) Add...

Embodiment 2

[0042] A green synthesis method of epoxy-modified starch-based emulsion, the content of each component in the formula is calculated by mass, and the unit is gram:

[0043] Oxidized starch: 30g

[0044] Hydrogen peroxide: 6g

[0045] Butyl acrylate: 10g

[0046] Methyl methacrylate: 20g

[0047] Epoxy resin E-51: 6g

[0048] Ammonium persulfate: 1g

[0049] Water 90g

[0050] Synthesis:

[0051] 1) Take each component according to the above-mentioned weight parts, and set aside;

[0052] 2) First mix the oxidized starch and water uniformly and then add it to a four-necked flask, heat it to 45-90°C under the action of hydrogen peroxide, and control the reaction time within 1-1.5h to obtain a gelatinized liquid with dispersion and stability;

[0053] 3) Dilute and disperse epoxy resin E-51 and butyl acrylate to obtain a uniformly dispersed mixed liquid. Add the mixed liquid dropwise to the gelatinized liquid, control the temperature at 80°C, and add the time for 60-80 minutes, and add at the sam...

Embodiment 3

[0056] A green synthesis method of epoxy-modified starch-based emulsion, the content of each component in the formula is calculated by mass, and the unit is gram:

[0057] Modified starch 30g

[0058] Hydrogen peroxide: 6g

[0059] Butyl acrylate: 10g

[0060] Styrene: 10g

[0061] Epoxy resin E-51: 10g

[0062] Ammonium persulfate: 0.41g

[0063] Sodium bisulfite: 0.19g

[0064] 80g of water

[0065] Synthesis:

[0066] 1) Take the components according to the above-mentioned weight parts and set aside;

[0067] 2) First mix the oxidized starch and water uniformly and then add it to a four-necked flask, heat it to 45-90°C under the action of hydrogen peroxide, and control the reaction time within 1-1.5h to obtain a gelatinized liquid with dispersion stability;

[0068] 3) Dilute and disperse epoxy resin E-51 and butyl acrylate to obtain a uniformly dispersed mixed liquid. Add the dispersed uniformly mixed liquid dropwise to the gelatinized liquid, control the temperature at 80°C, and the dropp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com