A kind of flame-retardant modified polyvinyl acetate emulsion and preparation method thereof

A technology of polyvinyl acetate and vinyl acetate, which is applied in the field of halogen-free flame-retardant copolymerized modified polyvinyl acetate emulsion and its preparation, can solve the problems such as the decline of mechanical properties, achieve the improvement of mechanical properties and thermal properties, and improve Stability and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

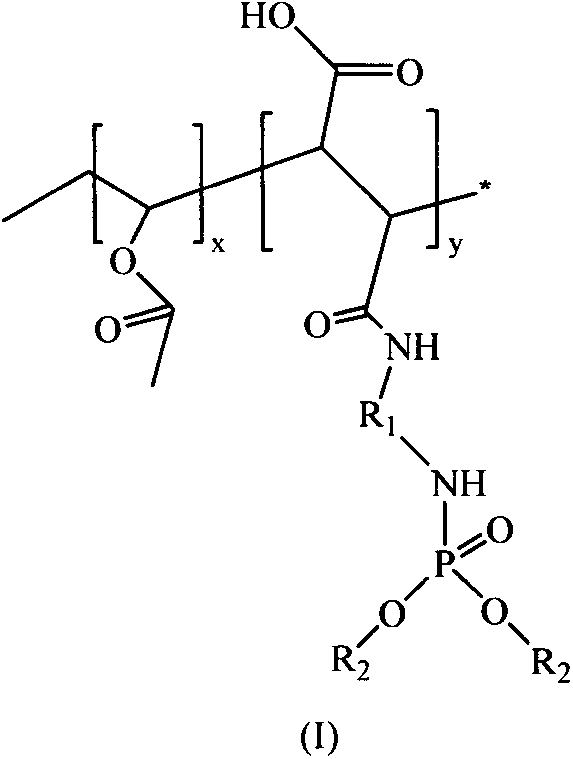

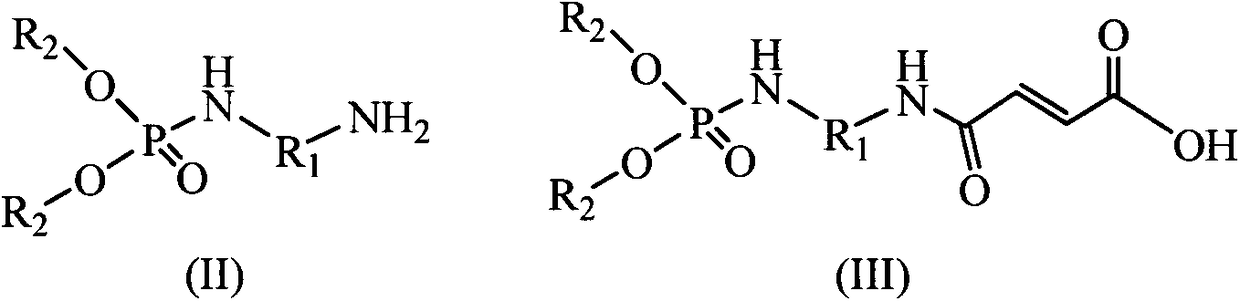

Method used

Image

Examples

Embodiment 1

[0032](1) Add 25.26g of dimethyl-2-amino-ethylphosphoramidate, 14.74g of maleic anhydride, 100g of vinyl acetate and 0.1g of terephthalate into a 250mL three-necked flask equipped with a reflux condenser and a thermometer. Phenol, stirred slowly to 72°C, and reacted for 3 hours to prepare a mixed solution containing intumescent flame retardant and vinyl acetate, which was set aside;

[0033] (2) 0.6g initiator potassium persulfate is dissolved in 50mL distilled water, stand-by;

[0034] (3) Add 450mL of distilled water, 0.5g of sodium lauryl sulfate, 1.0g of nonylphenol polyoxyethylene ether and 0.1g of sodium bicarbonate into a four-neck flask, and after it dissolves completely, add 42g of the above-mentioned expansion-type retardant After the mixture of fuel and vinyl acetate is pre-emulsified for 0.5 hours, the temperature is raised to 72°C;

[0035] (4) Add dropwise 33% of the initiator total amount in the mixture of step (3) gained, and finish dropwise in 20 minutes, whe...

Embodiment 2

[0038] (1) Add 13.03g dimethyl-2-amino-hexylphosphoramidate, 6.97g maleic anhydride, 100g vinyl acetate and 0.02g p-benzoquinone in a 250mL there-necked flask equipped with a reflux condenser and a thermometer, Stir and slowly raise the temperature to 40°C, react for 10 hours, and prepare a mixed solution containing intumescent flame retardant and vinyl acetate, which is ready for use;

[0039] (2) 0.2g initiator potassium persulfate is dissolved in 60mL distilled water, stand-by;

[0040] (3) Add 340mL of distilled water, 0.83g of sodium lauryl sulfate, 1.67g of nonylphenol polyoxyethylene ether and 0.2g of sodium bicarbonate into a four-neck flask, and after it is completely dissolved, add 48g of the above-mentioned expansion-type retardant After the mixture of fuel and vinyl acetate is pre-emulsified for 1 hour, the temperature is raised to 73°C;

[0041] (4) Add dropwise 40% of the initiator total amount in the mixture of step (3) gained, and finish dropwise in 15 minutes...

Embodiment 3

[0044] (1) Add 3.36g diethyl-2-amino-butyl phosphoramidate, 1.64g maleic anhydride, 100g vinyl acetate and 0.05g 2-tert-butyl in a 250mL three-necked flask equipped with a reflux condenser and a thermometer base hydroquinone, stirred slowly to 60°C, and reacted for 6 hours to prepare a mixed solution containing intumescent flame retardant and vinyl acetate, which was set aside;

[0045] (2) 0.45g initiator potassium persulfate is dissolved in 40mL distilled water, stand-by;

[0046] (3) Add 160mL of distilled water, 0.67g of sodium lauryl sulfate, 1.33g of nonylphenol polyoxyethylene ether and 0.15g of sodium bicarbonate into a four-neck flask, and add 31.5g of the above-mentioned expansion-type After the mixture of flame retardant and vinyl acetate is pre-emulsified for 0.8 hours, the temperature is raised to 76°C;

[0047] (4) Add dropwise 30% of the initiator total amount in the mixture of step (3) gained, and finish dropwise in 25 minutes, when hardly having monomer conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com