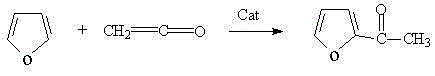

A kind of method for preparing 2-acetylfuran from ketene

A technology of acetylfuran and ketene, applied in the production field of chemical intermediate 2-acetylfuran, can solve the problems of low reactor production efficiency, low raw material utilization rate and high production cost, and achieves low corrosion, low raw material cost, three wastes The effect of low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 136g of furan, 1.0g of phosphoric acid, and 260g of chloroform into a four-necked flask equipped with an electric stirrer, a ketene gas pipe, a thermometer and an exhaust pipe, start stirring, and feed 85g of ketene within 3 hours at 15°C . After the solvent was recovered under normal pressure, rectification was carried out under reduced pressure. At -0.099Mpa, the 78-81°C fraction was collected to obtain 210.2g of 2-acetylfuran with a purity of 99% (the yield was 95.5% based on furan).

[0024] After solvent recovery is directly applied mechanically 6 times, the impact of recovery solvent mechanical application on product yield and purity is shown in the following table:

[0025] Apply times Yield(%) purity(%) 1 95.0 99.3 2 95.3 99.1 3 95.2 99.2 4 95.0 99.4 5 95.2 99.2 6 95.1 99.1

Embodiment 2

[0027] Add 68g of furan, 0.5g of phosphoric acid, and 150g of dichloromethane into a four-necked flask equipped with an electric stirrer, a ketene gas tube, a thermometer, and an exhaust pipe, start stirring, and feed ethylene at 20°C within 3 hours. Ketones 42.0g. After the solvent was recovered under normal pressure, rectification was carried out under reduced pressure. At -0.099Mpa, the 78-81°C fraction was collected to obtain 104.8g of 2-acetylfuran with a purity of 99.1% (the yield was 95.2% based on furan). .

Embodiment 3

[0029] Add 136g of furan, 1.0g of phosphoric acid, and 280g of dichloromethane into a four-necked flask equipped with an electric stirrer, a ketene gas tube, a thermometer, and an exhaust pipe, start stirring, and feed ethylene at 20°C within 3 hours. Ketones 86g. After the solvent was recovered under normal pressure, rectification was carried out under reduced pressure. At -0.099Mpa, the 78-81°C fraction was collected to obtain 209g of 2-acetylfuran with a purity of 99.3% (the yield was 95.0% based on furan).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com