Method for preparing benzimidazolone

A technology of benzimidazolone and o-phenylenediamine, which is applied in the field of chemical intermediate preparation, can solve the problems of high risk of pressurization process, large human injury, complicated waste liquid in the process, etc., and achieves easy absorption and utilization and material cost saving. , the effect of reducing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

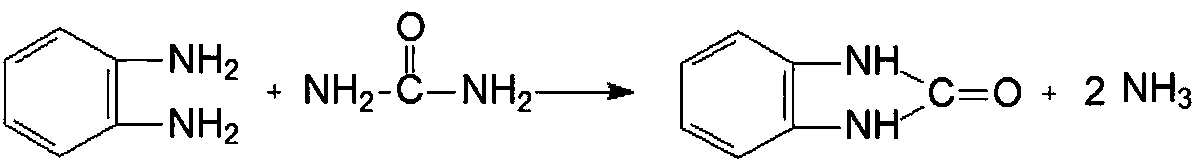

Image

Examples

Embodiment 1

[0025] In a 1000ml three-necked flask equipped with electric stirring, reflux condenser and thermometer, add 100g of urea, 100g of o-phenylenediamine, 200g of water and 10g of alkaline solvent, the pH value is 11, start the stirring and continue to heat up to 105°C, and keep the reaction temperature React for 4 hours. After the reaction, 100 g of water was distilled, cooled to room temperature, filtered, washed with water, and dried to obtain a white product with a yield of 99.6% and a purity of 99.5%. The mother liquor is recycled mechanically, and the product yield and the purity obtained after applying mechanically 4 times are as follows:

[0026] Apply times

[0027] As can be seen from the above table, the application of mother liquor has little impact on the purity and yield of the product. The solvent can be directly applied multiple times.

Embodiment 2

[0029] In a 1000ml three-neck flask equipped with electric stirring, reflux condenser and thermometer, add 130g of urea, 100g of o-phenylenediamine, 300g of water and 6g of alkaline solvent. React for 8 hours. After the reaction was completed, 210 g of water was distilled, cooled to room temperature, filtered, washed with water, and dried to obtain a white product with a yield of 99.3% and a purity of 99.4%.

Embodiment 3

[0031] In a 1000ml three-necked flask equipped with electric stirring, reflux condenser and thermometer, add 120g of urea, 100g of o-phenylenediamine, 100g of water and 7g of alkaline solvent, the pH value is 10, start the stirring and continue to heat up to 100°C, and keep the reaction temperature React for 10 hours. After the reaction was completed, 30 g of water was distilled, cooled to room temperature, filtered, washed with water, and dried to obtain a white product with a yield of 99.2% and a purity of 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com