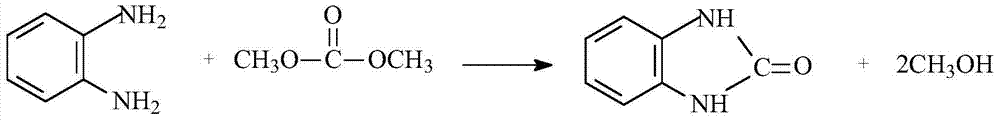

A kind of method for preparing benzimidazolone

A technology of benzimidazolone and o-phenylenediamine, applied in the field of chemical intermediate preparation, can solve the problems of serious equipment, dangerous phosgene, high odor, etc., and achieve the effects of easy reaction, easy absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In a 1000ml three-necked flask equipped with electric stirring, reflux condenser and thermometer, add 94.6g dimethyl carbonate, 108g o-phenylenediamine, 324g chlorobenzene and 0.108g phase transfer catalyst TEBA, heat up to solids are all dissolved, start stirring Continue to raise the temperature to 130°C, and keep the reaction system at 130°C for 4 hours. After completion of the reaction, cool down to room temperature, filter, wash with chlorobenzene, and dry to obtain 132 g of off-white product with a yield of 98.5% and a purity of 99.5%.

[0032] See the table below for the impact of mother liquor application on product yield and purity:

[0033] Apply times

[0034] As can be seen from the above table, the application of mother liquor has little impact on the purity and yield of the product. The solvent can be directly applied multiple times.

Embodiment 2

[0036] In a 1000ml three-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 94.6g dimethyl carbonate, 108g o-phenylenediamine, 1080g toluene and 0.108g phase transfer catalyst TEBA, heat up until all the solids are dissolved, start stirring and continue The temperature was raised to 110°C, and the reaction system was kept at 110°C for 8 hours. After completion of the reaction, cool down to room temperature, filter, wash with toluene, and dry to obtain 142 g of off-white product with a yield of 98.7% and a purity of 99.0%.

Embodiment 3

[0038] In a 1000ml three-necked flask equipped with electric stirring, reflux condenser and thermometer, add 94.6g dimethyl carbonate, 108g o-phenylenediamine, 324gDMSO and 0.324g phase transfer catalyst TEBA, heat up until the solids are completely dissolved, start stirring and continue to heat up To 150°C, the reaction system was kept at 150°C for 4 hours. After completion of the reaction, cool down to room temperature, filter, wash with DMSO, and dry to obtain 132 g of off-white product with a yield of 98.6% and a purity of 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com