Modified lithium titanate material and preparation method thereof

A kind of lithium titanate, lithium titanate technology, applied in the field of preparation of battery electrode materials, can solve the problems of reducing the tap density of materials, reducing the volume energy density, etc., to reduce the reaction temperature, shorten the preparation period and shorten the reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] By means of ultrasonic dispersion, 5.068g of lithium carbonate, 0.033g of manganese dioxide and 0.1864g of lanthanum trioxide were uniformly dispersed in the dispersant of 200mL of water and absolute ethanol, wherein the ratio of water and ethanol was 4:1 (volume ratio); measure 28.8 mL of butyl titanate and add dropwise at a rate of 3 mL / min into the aqueous ethanol solution dispersed with lithium carbonate, manganese dioxide and lanthanum trioxide; The solid powder was obtained after dehydration; the mixed powder was put into a muffle furnace for calcination at 700°C for 5 hours, cooled to room temperature with the furnace, and processed by high-energy ball milling at 400r / min for 5 hours to obtain the final product.

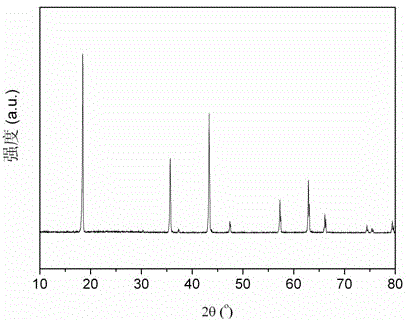

[0020] figure 1 is the XRD pattern of the obtained sample. It can be seen that the position and relative intensity of each diffraction peak in the XRD pattern of the synthesized product are similar to those of Li 4 Ti 5 o 12 The standard cards match...

Embodiment 2

[0022] Uniformly disperse 4.639g of lithium acetate, 0.0218g of hafnium dioxide and 0.0336g of neodymium trioxide into a dispersant of 200mL of water and absolute ethanol by ultrasonic dispersion, wherein the ratio of water and ethanol is 3:1 (volume ratio ); measure 14.7mL of butyl titanate and add dropwise at a rate of 3mL / min into the ethanol aqueous solution dispersed with lithium acetate, hafnium dioxide and neodymium trioxide; Finally, a solid powder was obtained; the mixed powder was put into a muffle furnace for calcination at 750°C for 6 hours, cooled to room temperature with the furnace, and subjected to high-energy ball milling at 400r / min for 4 hours to obtain the final product.

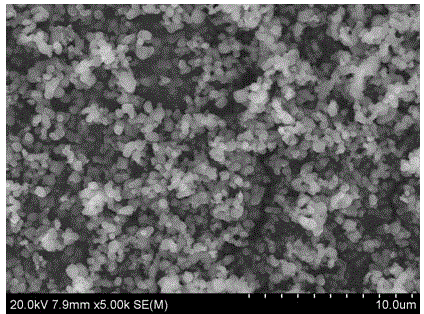

[0023] figure 2 The field emission scanning photo of the obtained sample shows that the particle distribution is relatively concentrated without obvious agglomeration, indicating that this method can prepare Li with a smaller particle size 4 Ti 5 o 12 .

Embodiment 3

[0025] Uniformly disperse 2.573g of lithium carbonate, 0.0169g of vanadium oxide and 0.0115g of manganese dioxide into 200mL of water and absolute ethanol dispersant by ultrasonic dispersion, wherein the ratio of water and ethanol is 3:1 (volume ratio); Measure 14.2mL of butyl titanate and add dropwise at a rate of 3mL / min into the ethanol aqueous solution dispersed with lithium carbonate, vanadium oxide and manganese dioxide; after the dropwise addition, continue ultrasonic dispersion for 30min, and obtain a solid powder after drying, grinding and dehydration ; Put the mixed powder into a muffle furnace for calcination at 800°C for 7 hours, cool down to room temperature with the furnace, and process it through high-energy ball milling at 400r / min for 6h to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com