Lithium ion positive electrode material cladded by nanometer alumina membrane and preparation method thereof

A nano-alumina, cathode material technology, applied in the field of materials, can solve the problems of reduced material charge and discharge efficiency, reduced material crystallization performance, and poor cathode material performance, and achieves stable diffusion rate, uniform coating, and improved cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

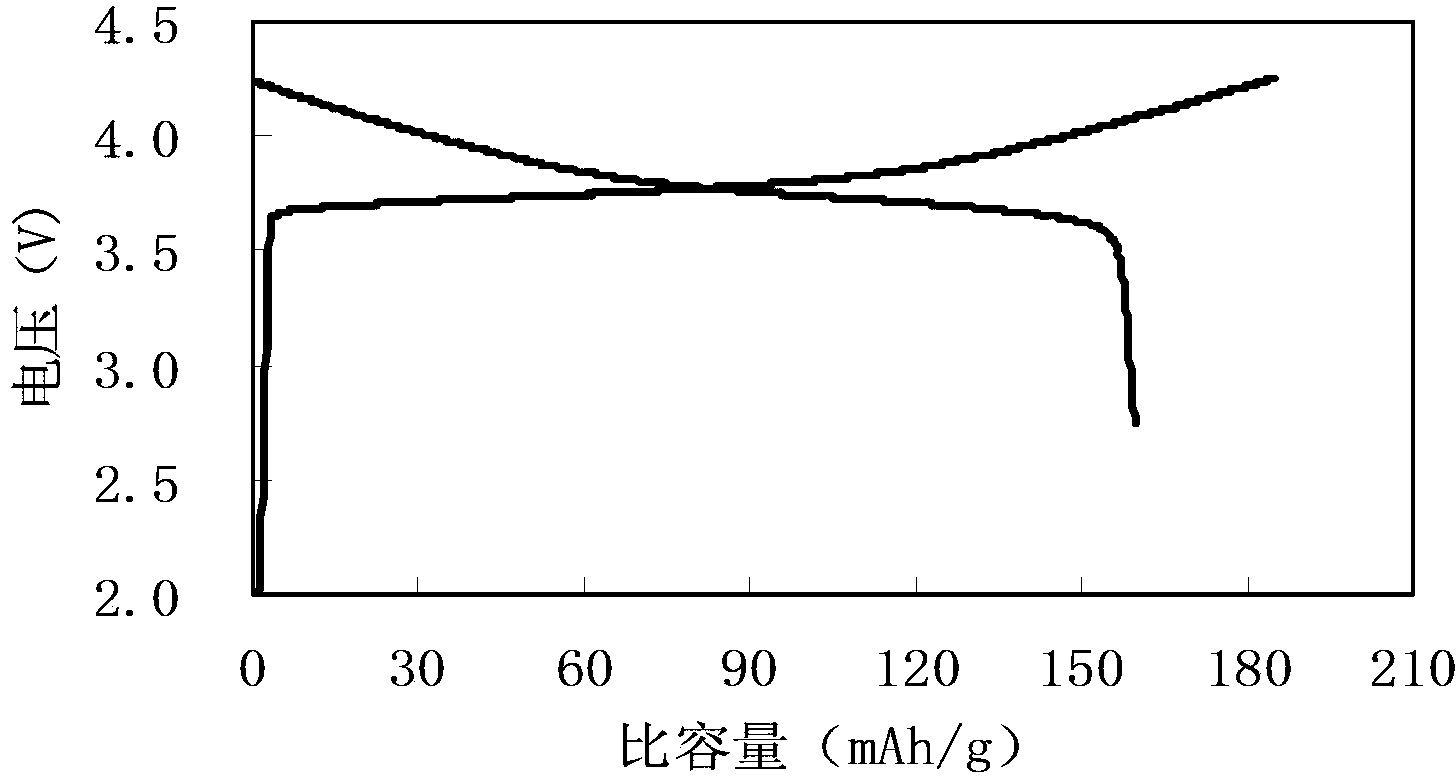

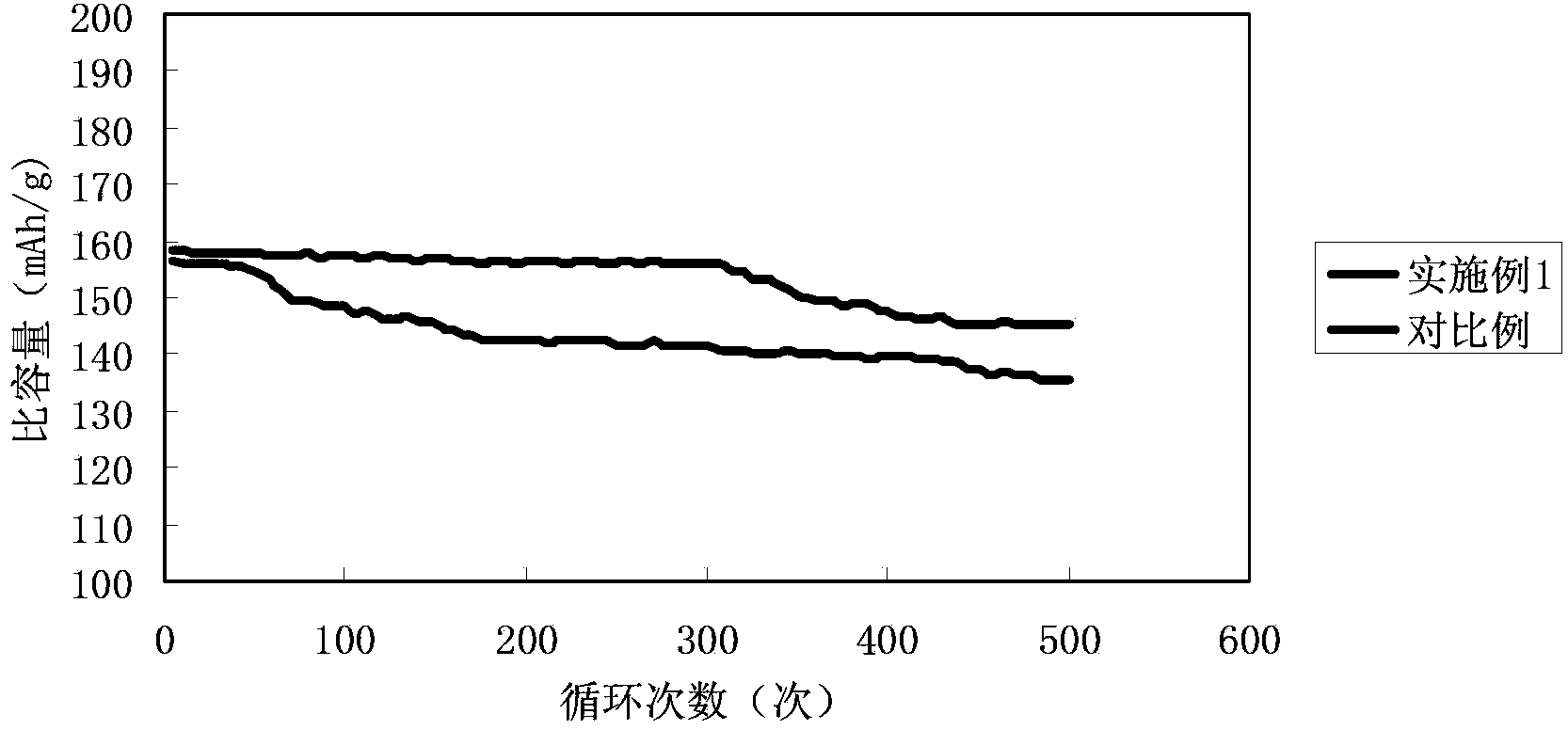

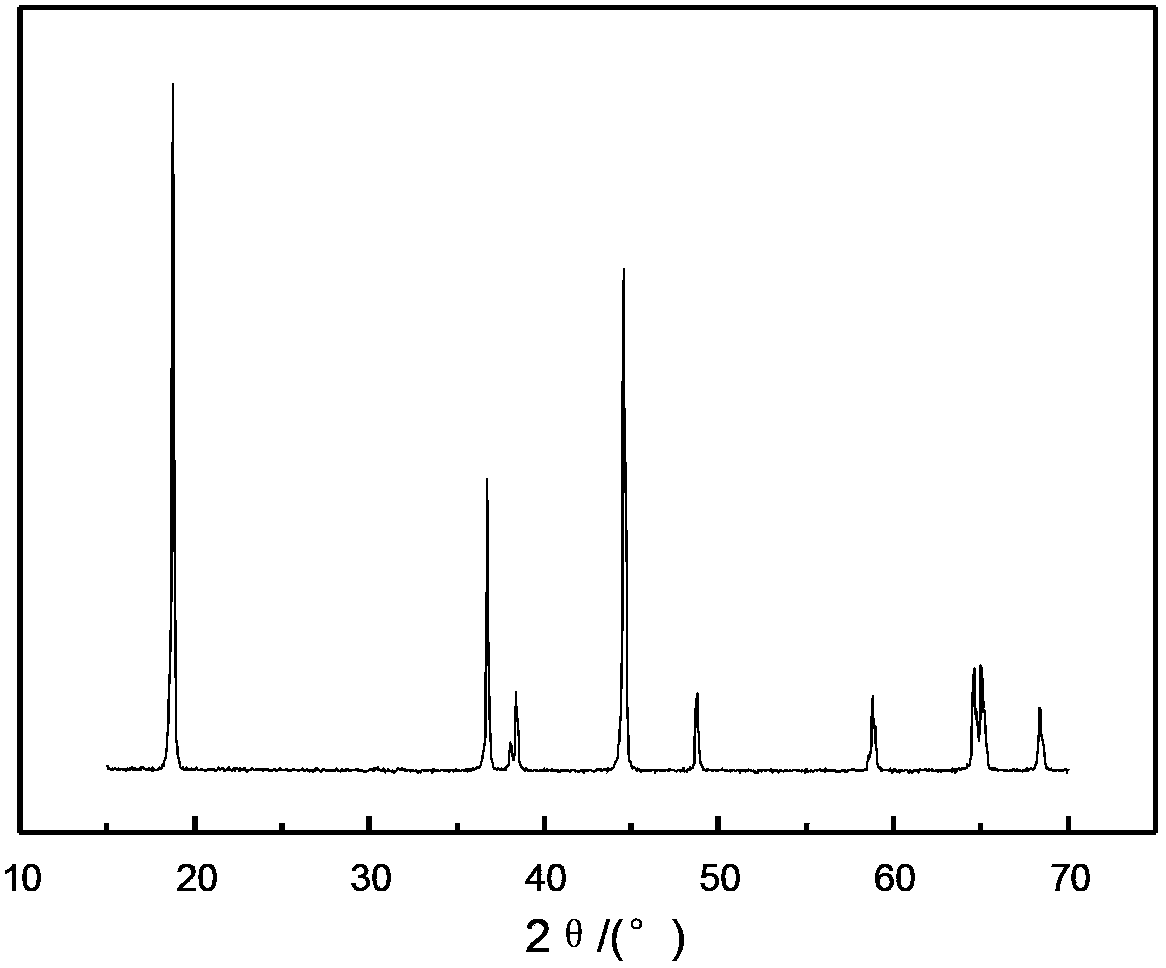

Embodiment 1

[0023] 50g of LiNi with an average particle size of 10um 0.5 co 0.2 mn 0.3 o 2 Mix the positive electrode material with the deionized aqueous solution with a concentration of 0.3M sodium bicarbonate evenly, then slowly add the aluminum chloride solution with a concentration of 0.08M into the mixed solution of the positive electrode material, control the temperature at 50°C, and keep stirring, while adding Adjust the pH value of the solution to 8.5 with an appropriate amount of ammonia water, stir for 30 minutes, then stand still for 60 minutes, then filter, wash, and dry the solution at 80°C for 6 hours. After drying, it can be calcined at 400°C for 6 hours under oxygen atmosphere. A positive electrode material coated with a nano-alumina film is obtained, and the thickness of the nano-film is 10 nm. Use this material as the positive electrode material to make a button battery. The lithium sheet is the negative electrode. The charge and discharge cut-off voltage is 2.75v-4.2...

Embodiment 2

[0025] 50g of LiNi with an average particle size of 10um 0.5 co 0.2 mn 0.3 o 2 Mix the positive electrode material with a deionized aqueous solution with a concentration of 1M sodium bicarbonate evenly, then slowly add a 0.15M aluminum sulfate solution into the mixed solution of the positive electrode material, keep the temperature at 52°C, and keep stirring, while adding an appropriate amount of Adjust the pH value of the solution with ammonia water to 9, stir for 30 minutes, then stand still for 60 minutes, then filter, wash, and dry the solution at 80°C for 6 hours, and then calcinate at 400°C for 6 hours under an oxygen atmosphere to obtain nano A positive electrode material coated with aluminum oxide film, the thickness of the nano film is 14nm. Use this material as the positive electrode material to make a button battery. The lithium sheet is the negative electrode. The charge and discharge cut-off voltage is 2.75v-4.25v. Under the condition of 2c discharge current, t...

Embodiment 3

[0027] 50g of LiNi with an average particle size of 10um 0.5 co 0.2 mn 0.3 o 2 Mix the positive electrode material with the deionized aqueous solution with a concentration of 1.5M sodium bicarbonate evenly, then slowly add the aluminum chloride solution with a concentration of 0.2M into the mixed solution of the positive electrode material, keep the temperature at 50°C, and keep stirring while adding Adjust the pH of the solution to 9.5 with an appropriate amount of ammonia water, stir for 30 minutes, then stand still for 60 minutes, then filter, wash, and dry the solution at 80°C for 6 hours, and then calcine at 500°C for 6 hours under an oxygen atmosphere. A positive electrode material coated with a nano-alumina film is obtained, and the thickness of the nano-film is 20 nm. Use this material as the positive electrode material to make a button battery. Lithium sheet is the negative electrode. Under current conditions, the capacity of 500 cycles is maintained at 144.2mAh / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com