Graphene/transition metal oxide composite cathode material and preparation method thereof

A transition metal and negative electrode material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problem of poor high-rate performance of graphene/transition metal oxides, high rate, unsatisfactory long-term cycle performance, and inability to effectively provide Problems such as electron transfer channels, to achieve high long-term cycle stability, avoid volume changes and agglomeration problems, and achieve good long-term cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 16g iron nitrate (Fe(NO 3 ) 3 ·6H 2 (2) and 2g of graphene nanosheets, mixed with 40ml of absolute ethanol, ultrasonically mixed evenly, and then magnetically stirred in a water bath at 80°C until the absolute alcohol was completely volatilized. Put the dried mixture into a carbonization furnace, and raise the temperature from room temperature to 500 °C at a rate of 1.5 °C / min under a nitrogen atmosphere, keep it warm for 3 hours, and then cool it down to room temperature. That is, the graphene / iron oxide composite material is obtained. Wherein the content of iron oxide is 80wt%, the content of graphene nano sheet is 20wt%, and the size of graphene sheet is 0.5-10μm.

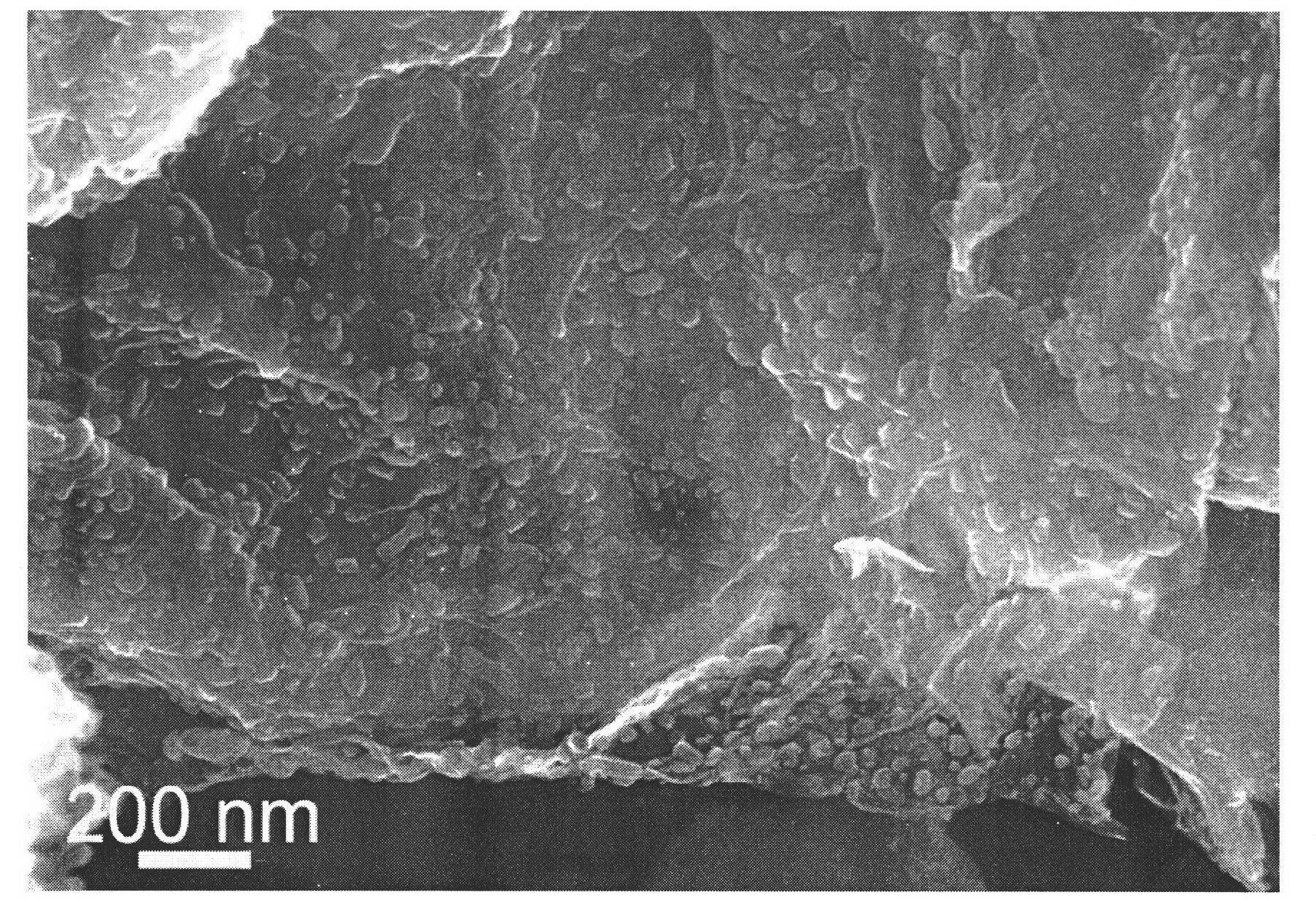

[0030] as attached figure 1 The iron oxide nanoparticles shown by the scanning electron microscope (SEM) are loaded on the graphene nanosheets, the iron oxide nanoparticles have a diameter ranging from 5 to 50 nm, and the graphene nanosheets have 1 to 10 layers;

[0031] as attached Figure 5 ...

Embodiment 2

[0034] Weigh 0.8 copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) and 2g graphene nanosheets, mixed with 40ml acetone, ultrasonically mixed, then magnetically stirred in a water bath at 50°C until the acetone was completely volatilized. Put the dried mixture into a carbonization furnace, and raise the temperature from room temperature to 200 °C at a rate of 1.5 °C / min under a nitrogen atmosphere, keep it warm for 5 hours, and then cool it down to room temperature. That is, the graphene / copper oxide composite material is obtained. Wherein the content of copper oxide is 30wt%, the content of graphene nano sheet is 70wt%, and the size of graphene sheet is 1-15μm.

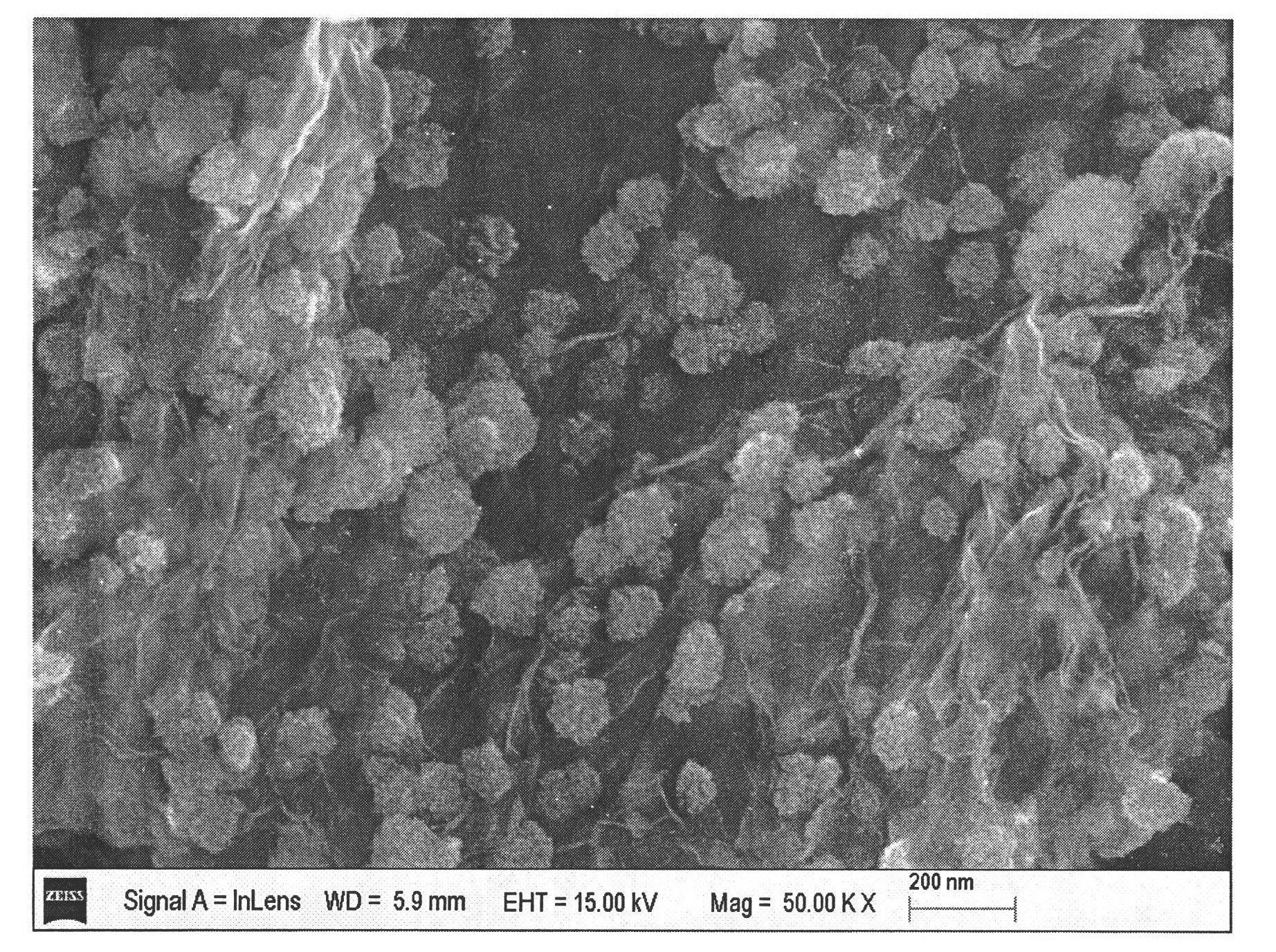

[0035]as attached figure 2 Scanning electron microscope (SEM) analysis shows that the copper oxide nanoparticles are loaded on the graphene nanosheets, and the diameter of the copper oxide nanoparticles ranges from 10 to 30 nm.

[0036] The electrochemical performance test results show that the reversible capacity of the com...

Embodiment 3

[0038] Weigh 20 cobalt nitrate (Co(NO 3 ) 2 ·3H 2 O) and 1g of graphene nanosheets, mixed with 40ml N-methylpyrrolidone, ultrasonically mixed, and then magnetically stirred in a water bath at 60°C until the N-methylpyrrolidone was completely volatilized. Put the dried mixture into a carbonization furnace, and raise the temperature from room temperature to 600 °C at a rate of 1.5 °C / min under a nitrogen atmosphere, keep it warm for 0.5 hours, and then cool to room temperature. That is, the graphene / cobalt oxide composite material is obtained. Wherein the content of cobalt oxide is 95wt%, the content of graphene nano sheet is 5wt%, and the size of graphene sheet is 2-20μrn.

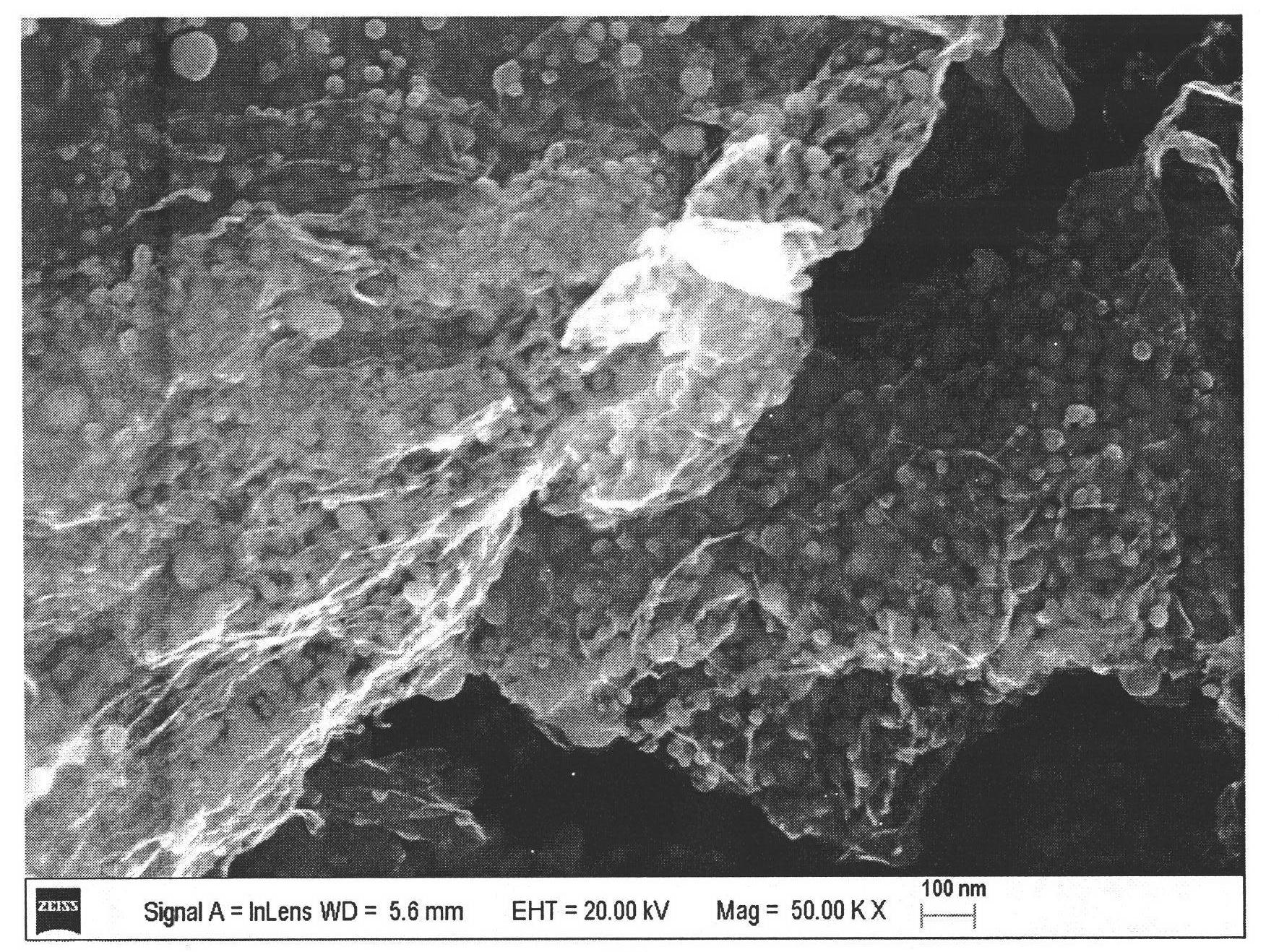

[0039] as attached image 3 The cobalt oxide nanoparticles shown by the scanning electron microscope (SEM) are loaded on the graphene nanosheets, the diameter of the cobalt oxide nanoparticles ranges from 15 to 80 nm, and the graphene nanosheets have 1 to 10 layers;

[0040] The electrochemical perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com