PEO-based gel polymer electrolyte and preparation method thereof

A gel polymer and electrolyte technology, applied in the field of electrolytes, can solve the problems of low conductivity and achieve the effects of improving conductivity, increasing the number of migration, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

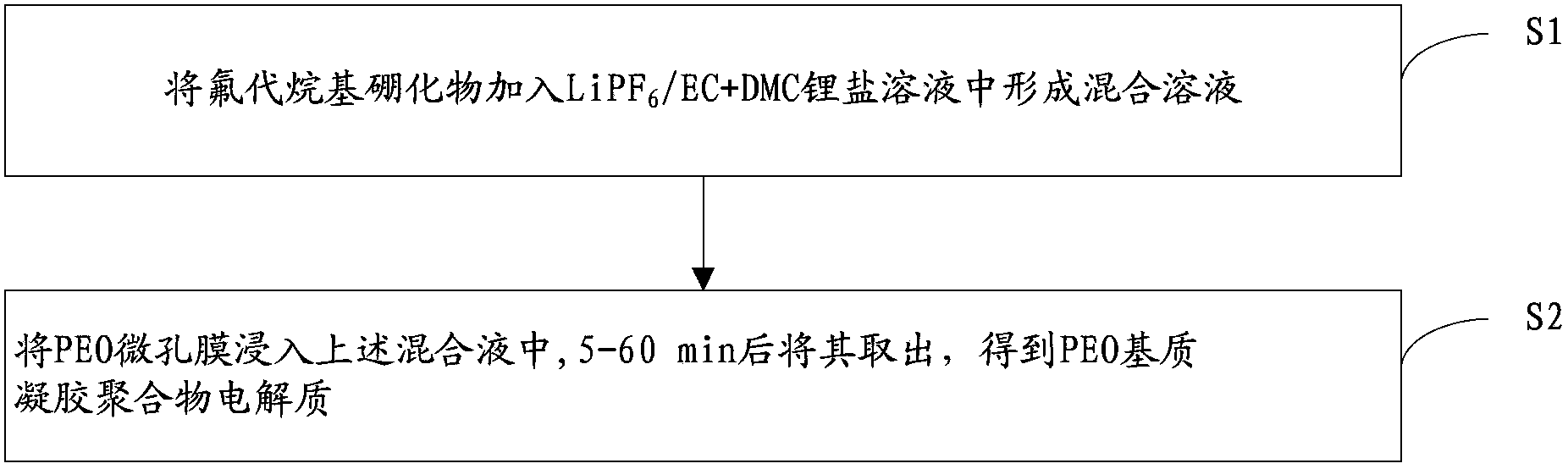

[0022] The preparation method of above-mentioned PEO matrix gel polymer electrolyte, such as figure 1 shown, including the following steps:

[0023] S1, adding fluoroalkylboride to LiPF 6 / EC+DMC lithium salt solution, ultrasonically dispersed to form a mixed solution; among them, LiPF 6 The molar ratio to fluoroalkylboride is 1:0.001~1:0.05;

[0024] S2. Immerse the dried PEO microporous membrane into the above mixed solution, take it out after 5-60 minutes, and obtain the PEO matrix gel polymer electrolyte.

[0025] The preparation method of the PEO matrix gel polymer electrolyte, in step S1, the LiPF 6 The molar ratio to fluoroalkylboride is 1:0.02~1:0.05.

[0026] The preparation method of the PEO matrix gel polymer electrolyte, in step S1, in step S1, the LiPF 6 The molar concentration of / EC+DMC lithium salt solution is 1mol / L; the volume ratio of EC to DMC is 1:2.

[0027] The preparation method of the PEO matrix gel polymer electrolyte, in step S1, in step S1, th...

Embodiment 1

[0032] In the glove box, the additive (C 6 h 3 F)O 2 B(C 6 h 3 f 2 ) ultrasonic (ultrasonic 30min) dispersed in 1mol / L LiPF 6 In the solution of / EC+DMC (the volume ratio of EC and DMC is 1:2; the volume numbers are 10 and 20ml respectively), a mixed solution is formed, wherein, LiPF 6 with (C 6 h 3 F)O 2 B(C 6 h 3 f 2 ) in a molar ratio of 1:0.05; then immerse the dried PEO microporous membrane in the above mixed solution, take it out after 60min, and obtain the added (C 6 h 3 F)O 2 B(C6H 3 f 2 ) PEO-based gel polymer electrolyte.

Embodiment 2

[0034] In the glove box, the additive (C 6 f 4 )O 2 B(C 6 f 5 ) ultrasonic (ultrasonic 25min) dispersed in 1mol / L LiPF 6 In the solution of / EC+DMC (the volume ratio of EC and DMC is 1:2; the volume numbers are 8 and 16ml respectively), a mixed solution is formed, wherein, LiPF 6 with (C 6 f 4 )O 2 B(C 6 f 5 ) in a molar ratio of 1:0.04; then immerse the dried PEO microporous membrane in the above mixed solution, take it out after 40min, and obtain the added (C 6 f 4 )O 2 B(C 6 f 5 ) of PEO matrix gel polymer electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com