Method for smashing coal gangue through rollers at high pressure and recovering coal

A technology of coal gangue and high-pressure roller, which is applied in the field of high-pressure roller crushing of coal gangue and recovery of coal, and coal gangue processing, which can solve problems such as environmental pollution and land occupation, and achieve improved sorting accuracy, reasonable recycling and utilization, and reduced The effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

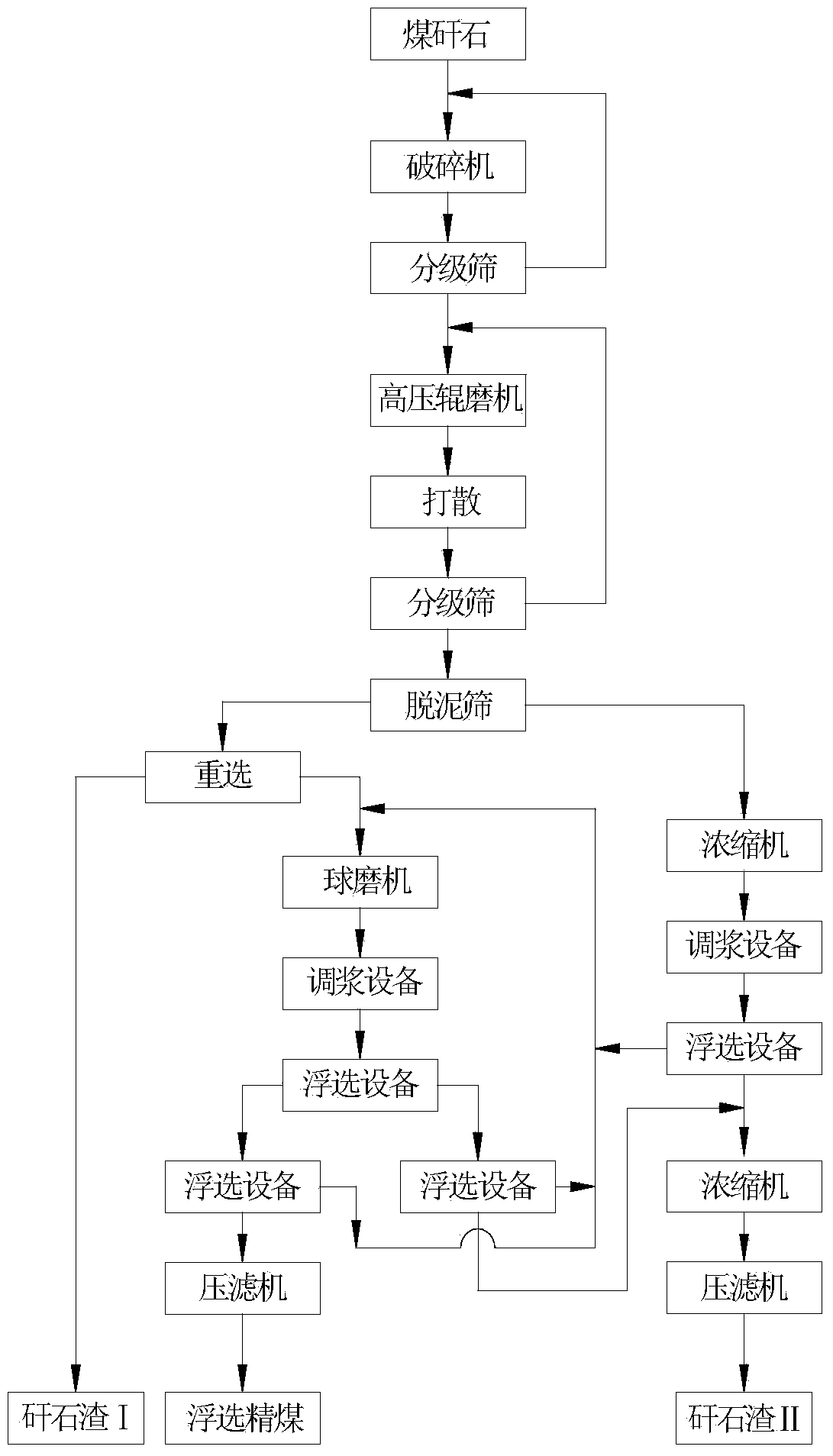

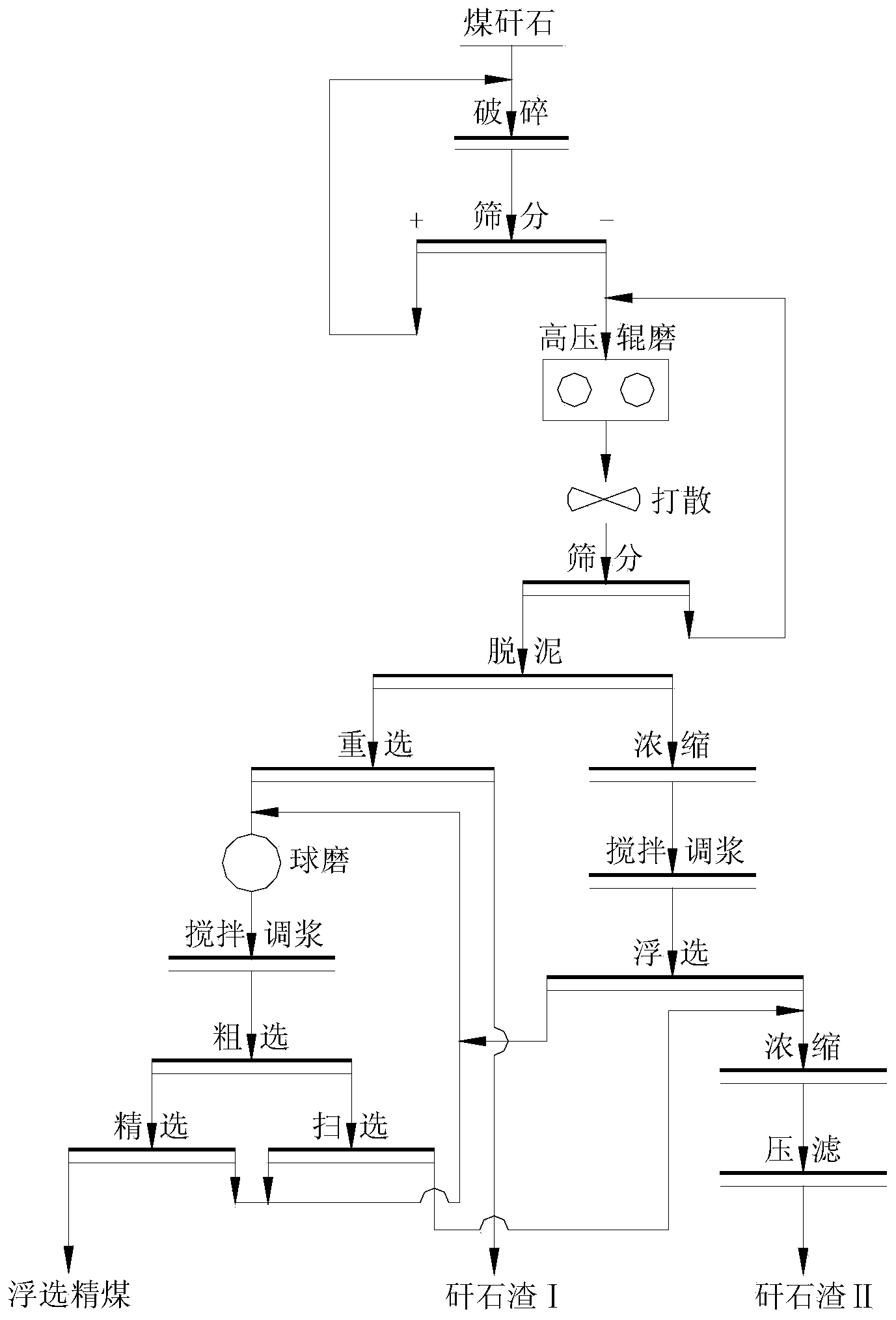

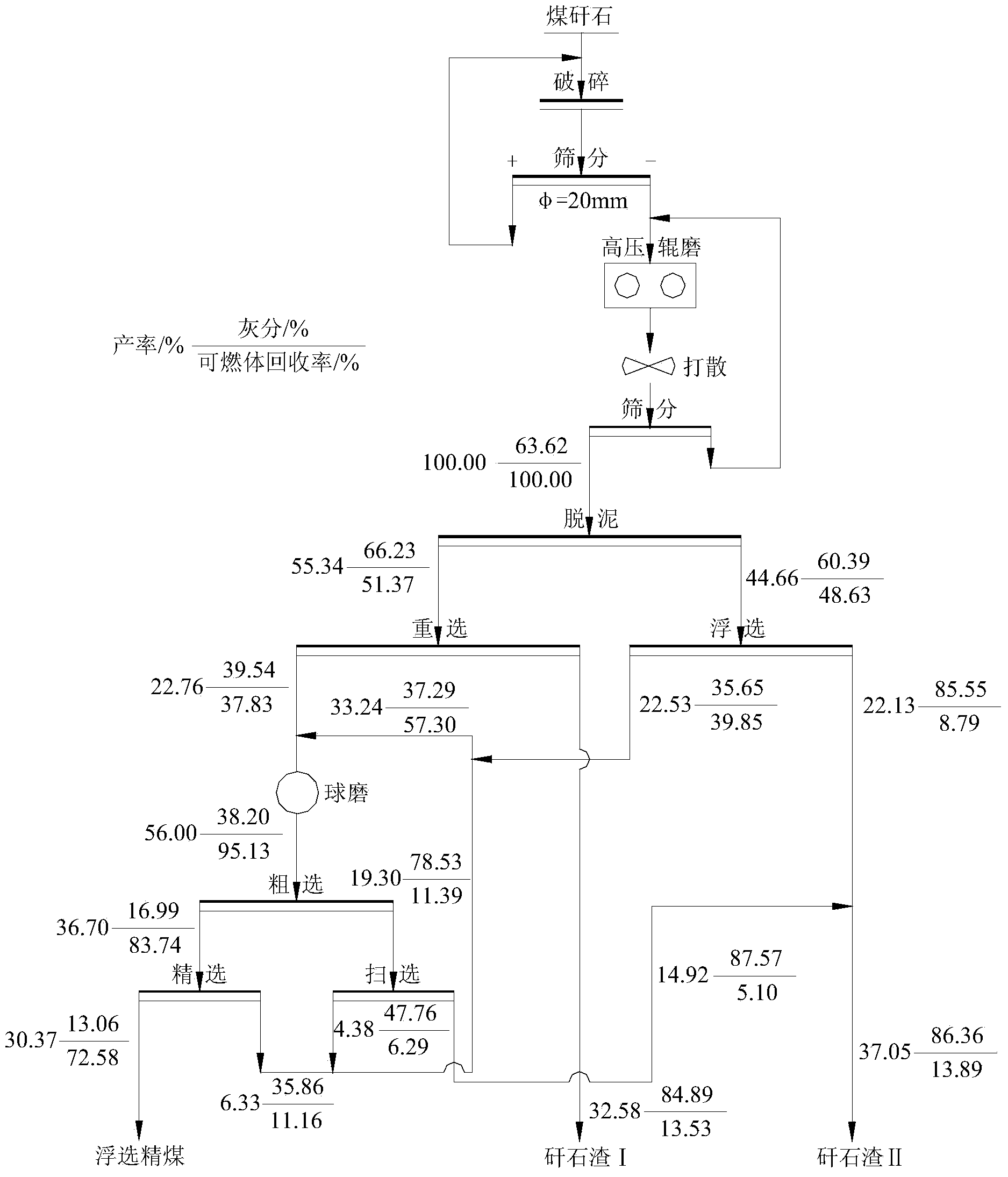

[0022] Coal gangue is the washing gangue of the coking coal washing plant, and the ash content is 63.62%. Use high-pressure roller mills to classify coal gangue after superfine crushing. The process steps are as follows:

[0023] (1) Use a jaw crusher to crush the coal gangue to a feed particle size suitable for high-pressure roller mill crushing below 20mm;

[0024] (2) Carry out high-pressure roller mill ultra-fine crushing to the crushed coal gangue. The pressure between the rollers during the high-pressure roller mill work is 5.5MPa, the roll speed is 1.6m / min, and the roll gap is 3mm. After the high-pressure roller mill is ultra-fine crushed The product should be sieved with a sieve with a sieve hole of 3mm. The material on the sieve is returned to the high-pressure roller mill to be combined with the new feed material and then crushed. The material under the sieve is deslimed. The products after sliming should be re-selected on a shaking table to obtain coarse clean coa...

Embodiment 2

[0029] Coal gangue is the washing gangue of the coking coal washing plant, and the ash content is 71.79%. Use high-pressure roller mills to classify coal gangue after superfine crushing. The process steps are as follows:

[0030] (1) Use a cone crusher to crush the coal gangue to a feed particle size suitable for high-pressure roller mill crushing below 20mm;

[0031] (2) Carry out high-pressure roller mill ultra-fine crushing to the crushed coal gangue. The pressure between the rollers during the high-pressure roller mill work is 6.0MPa, the roll speed is 1.0m / min, and the roll gap is 3mm. After the high-pressure roller mill is ultra-fine crushed The product should be sieved with a sieve with a sieve hole of 3mm. The material on the sieve is returned to the high-pressure roller mill to be combined with the new feed material and then crushed. The material under the sieve is deslimed. The products after the slime are re-selected by a spiral separator to obtain coarse clean coa...

Embodiment 3

[0036] Coal gangue is the washing gangue of the coking coal washing plant, and the ash content is 71.91%. Use high-pressure roller mills to classify coal gangue after superfine crushing. The process steps are as follows:

[0037](1) Use a jaw crusher to crush the coal gangue to a feed particle size suitable for high-pressure roller mill crushing below 50 mm;

[0038] (2) Carry out high-pressure roller mill ultra-fine crushing to the crushed coal gangue, the pressure between the rollers when the high-pressure roller mill is working is 4.0MPa, the roll speed is 3.0m / min, the roll gap is 6mm, and the high-pressure roller mill is ultra-fine. The product should be sieved with a sieve with a sieve hole of 6mm. The material on the sieve is returned to the high-pressure roller mill to be combined with the new feed material and then crushed. The material under the sieve is deslimed. The products after the slime are re-selected by a spiral separator to obtain coarse clean coal I and ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com