Method for extracting collagen polypeptide from fish scale

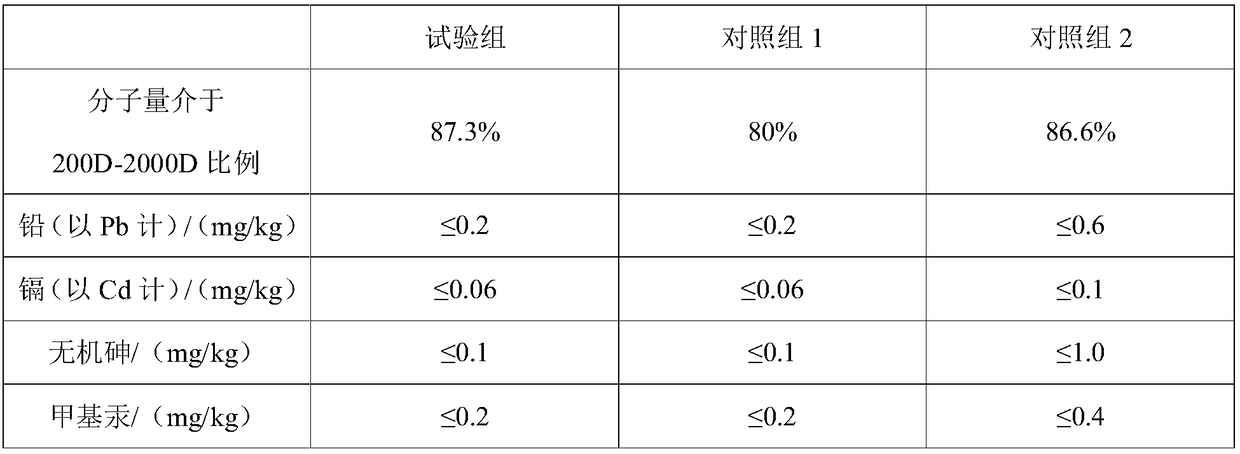

A collagen peptide, fish scale collagen technology, applied in chemical instruments and methods, animal/human proteins, specific peptides, etc., can solve the problems of incomplete hydrolysis, waste of nutrients, high content of heavy metals, and achieve high stability, The effect of promoting absorption and reducing the content of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for extracting collagen peptides from fish scales includes: pretreatment, extraction, hydrolysis, metal removal, and purification. The specific steps are as follows:

[0026] Pretreatment: Take fish scales, wash with clean water, dry at low temperature, smash, soak in 1% citric acid solution for 24 hours, stir intermittently, change the solution once every 12 hours, rinse with deionized water to neutrality after soaking, and filter; then Soak in 0.03% sodium hydroxide solution for 24 hours, stirring intermittently, and change the solution once every 12 hours. After soaking, rinse with deionized water to neutrality and filter; pretreatment can remove calcium and non-collagen substances in fish scales to facilitate Further extraction of collagen;

[0027] Extraction: Place the pretreated fish scales in a 0.05mol / L citric acid solution system, add 0.3% papain restriction enzyme digestion of the substrate weight, control the temperature at 5°C, the ultrasonic frequenc...

Embodiment 2

[0034] The method for extracting collagen peptides from fish scales includes: pretreatment, extraction, hydrolysis, metal removal, and purification. The specific steps are as follows:

[0035] Pretreatment: Take fish scales, wash with clean water, dry at low temperature, crush, soak in 1% citric acid solution for 32 hours, stir intermittently, change the solution every 16 hours, rinse with deionized water to neutrality after soaking, and filter; then Soak in 0.04% sodium hydroxide solution for 32 hours, stirring intermittently, and change the solution every 16 hours. After soaking, rinse with deionized water to neutrality and filter; pretreatment can remove calcium and non-collagen substances in fish scales to facilitate Further extraction of collagen;

[0036] Extraction: Place the pretreated fish scales in a 0.06mol / L citric acid solution system, add 0.4% papain restriction enzyme hydrolysis of the substrate weight, control the temperature at 6°C, the ultrasonic frequency at 35kH...

Embodiment 3

[0043] The method for extracting collagen peptides from fish scales includes: pretreatment, extraction, hydrolysis, metal removal, and purification. The specific steps are as follows:

[0044] Pretreatment: Take fish scales, wash with clean water, dry at low temperature, crush, soak in 2% citric acid solution for 36 hours, stir intermittently, change the solution once in 18 hours, rinse with deionized water to neutrality after soaking, and filter; then Soak in 0.05% sodium hydroxide solution for 36 hours, stir intermittently, and change the solution once 18 hours. After soaking, rinse with deionized water to neutrality and filter; pretreatment can remove calcium and non-collagen substances in fish scales to facilitate Further extraction of collagen;

[0045] Extraction: Place the pretreated fish scales in a 0.08mol / L citric acid solution system, add 0.5% papain restriction enzyme digestion of the substrate weight, control the temperature at 10°C, the ultrasonic frequency at 45kHz, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com