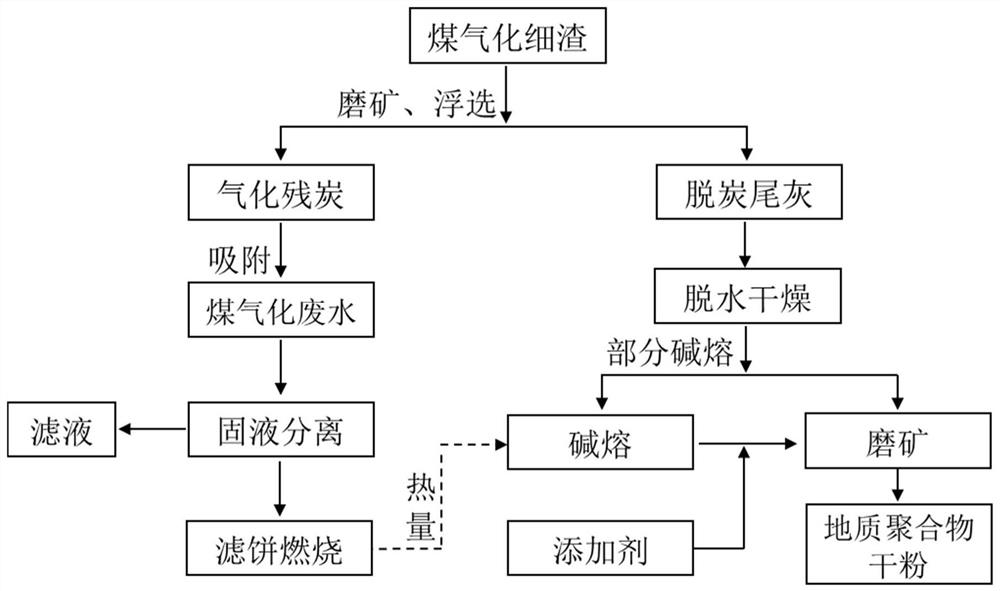

All-component comprehensive utilization method of coal gasification fine slag

A coal gasification and full-component technology, which is applied in chemical instruments and methods, solid waste removal, water treatment parameter control, etc., can solve the problems of high treatment cost and cumbersome process, and achieve simple process, reduced consumption, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The coal-to-oil gasification fine slag produced by Ningxia Coal Industry Group Co., Ltd. is used as the raw material for all components in this embodiment 1. The coal gasification fine slag composition is SiO 2 : 53.43%, Al 2 o 3 : 18.72%, Fe 2 o 3 : 10.65%, CaO: 7.97%, MgO: 2.95%, loss on ignition: 21.83%.

[0029] Proceed as follows:

[0030] S1. After the above samples are ground to a particle size of less than 74 μm by a ball mill, flotation is carried out using a hydrocarbon compound agent as a collector and 2-octanol as a foaming agent. Collect the flotation concentrate, i.e. gasification residual carbon, and collect the flotation tailings, i.e. decarbonization tail ash for later use. Among them, the flotation yield is 42.98%, the loss on ignition is 46.28%, and the flotation tailings yield is 57.02%. The loss on ignition was 3.4%.

[0031] S2. The collected gasification residual carbon is used as an adsorbent, put into the coal gasification wastewater and f...

Embodiment 2

[0037] The gasification fine slag produced by the coal gasification of Yankuang and Lunan is the raw material used in the whole component in this embodiment 2, and the composition of the coal gasification fine slag is SiO 2 : 51.04%, Al 2 o 3 : 11.83%, Fe 2 o 3 : 13.49%, CaO: 12.54%, MgO: 1.28%, loss on ignition: 22.93%.

[0038] Proceed as follows:

[0039] S1. After the above samples are ground to a particle size of less than 74 μm by a ball mill, flotation is carried out using a hydrocarbon compound agent as a collector and 2-octanol as a foaming agent. Collect the flotation concentrate, i.e. gasification residual carbon, and collect the flotation tailings, i.e. decarbonization tail ash for later use, among which the flotation yield is 38.91%, the loss on ignition is 46.10%, the flotation tailings yield is 61.09%, and the incineration The loss is 3.2%.

[0040] S2. The collected gasification residual carbon is used as an adsorbent, put into the coal gasification wastewa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com