Extraction method for coconut oil

An extraction method, coconut oil technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of browning of coconut meat, high cost, residual organic solvents, etc., reduce the degree of water emulsification, increase the degree of destruction, and increase the degree of free degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

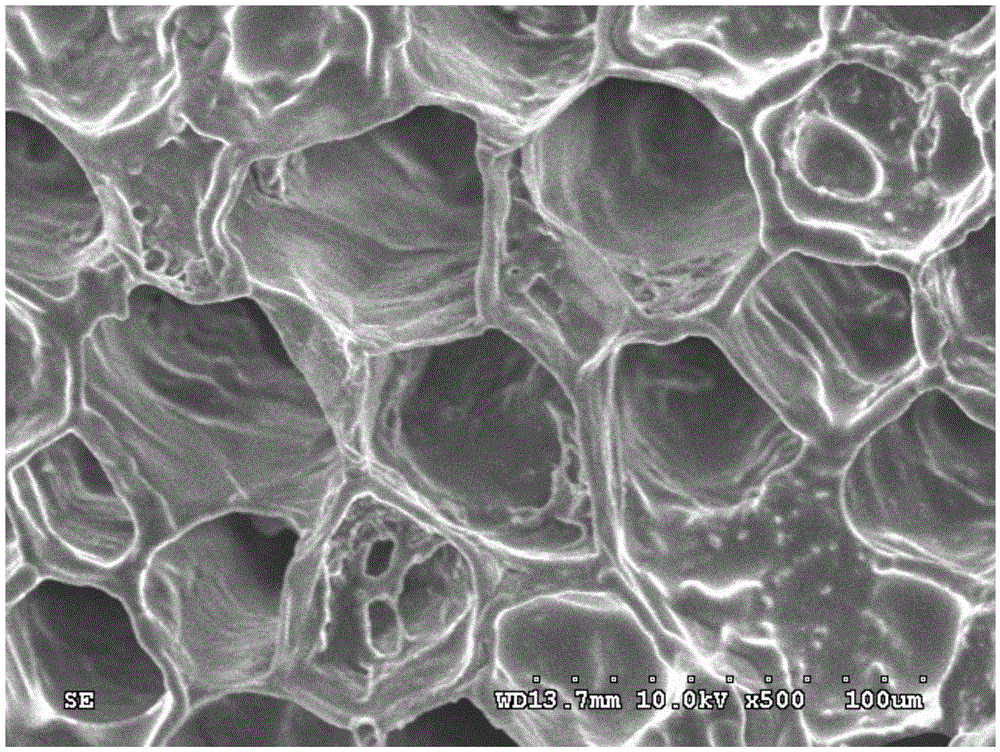

[0025] 1) drying and crushing: 100g coconut meat is cleaned and cut into 5cm long, 5cm wide, and 2cm thick strips, then put the cut coconut meat into a vacuum freezer for vacuum freeze-drying, the vacuum degree is 1Pa, and the temperature is -40 ℃ of drying 20h, the electron microscope figure of present embodiment coconut meat after vacuum freeze-drying is as follows figure 1 After drying, take it out and store it in a cool, dry place under airtight seal. The coconut meat processed by vacuum freeze-drying is crushed to a paste state, and then taken out for later use.

[0026] 2) enzymolysis: the coconut meat after pulverizing is added 500g water and mixes and makes mixture I, adds the composite enzyme of 0.5% of mixture I weight, and described composite enzyme is that cellulase and papain are mixed, and described cellulose The mass ratio of enzyme to papain is 1:0.5, and the enzyme is hydrolyzed in a water bath at 45°C for 12 hours. Inactivate the enzyme at 85°C for 30 minut...

Embodiment 2

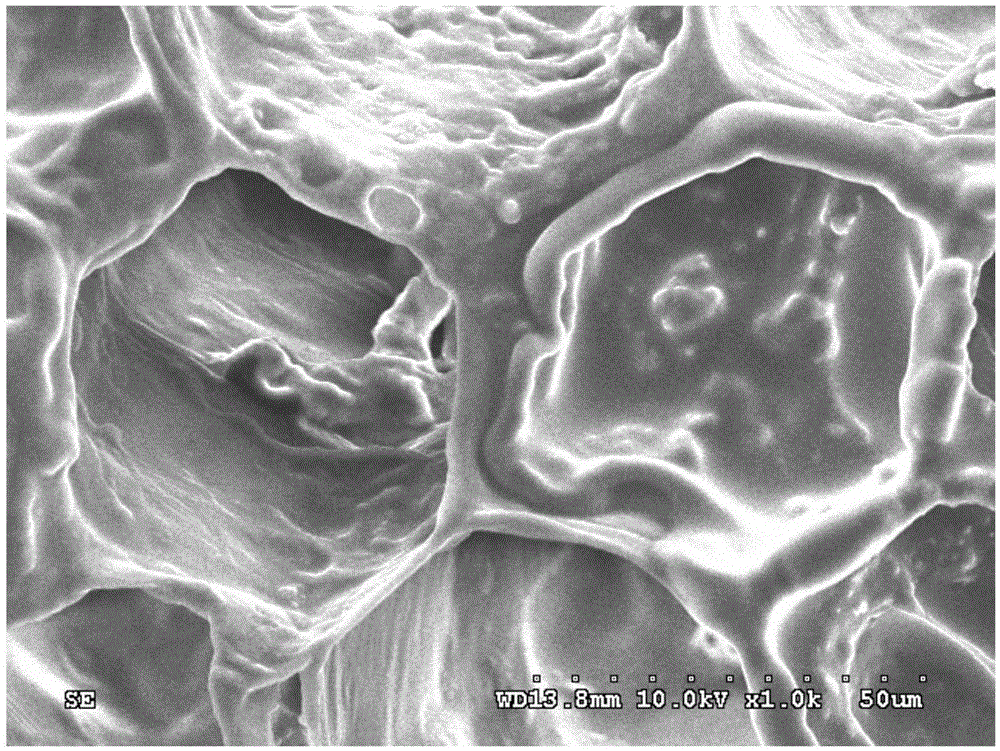

[0029] 1) drying and crushing: 100g coconut meat is cleaned and cut into 5cm long, 5cm wide, and 2cm thick strips, then put the cut coconut meat into a vacuum freezer for vacuum freeze-drying, the vacuum degree is 5Pa, and the temperature is -60 ℃ of drying 48h, the electron microscope figure of present embodiment coconut meat after vacuum freeze-drying is as follows figure 2 After drying, take it out and store it in a cool, dry place under airtight seal. The coconut meat processed by vacuum freeze-drying is crushed to a paste state, and then taken out for later use.

[0030] 2) Enzymolysis: add 500g of water to the coconut meat after pulverizing and mix to prepare mixture I, add 1% compound enzyme of mixture I weight, described compound enzyme is that cellulase and papain are mixed, and described cellulose The mass ratio of enzyme to papain is 1:1.5, and the enzyme is hydrolyzed in a water bath at 50°C for 24 hours. Inactivate the enzyme at 85°C for 30 minutes to prepare m...

Embodiment 3

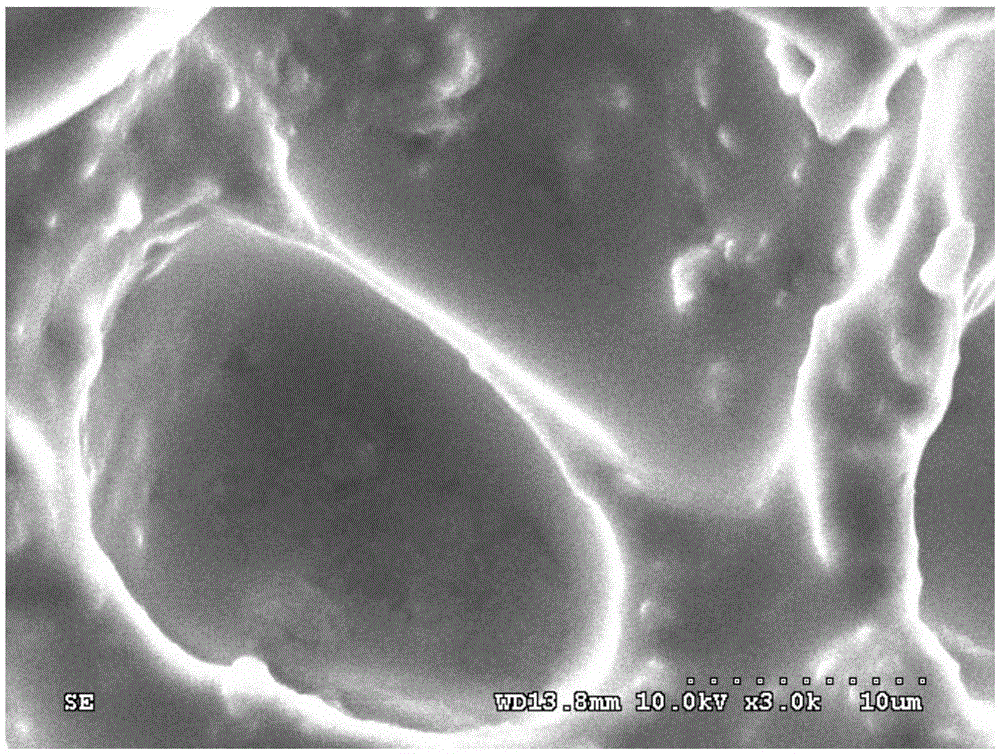

[0033] 1) drying and crushing: 100g coconut meat is cleaned and cut into 5cm long, 5cm wide, and 2cm thick strips, then put the cut coconut meat into a vacuum freezer for vacuum freeze-drying, the vacuum degree is 10Pa, and the temperature is -80 ℃ of drying 48h, the electron microscope figure of present embodiment coconut meat after vacuum freeze-drying is as follows image 3 After drying, take it out and store it in a cool, dry place under airtight seal. The coconut meat processed by vacuum freeze-drying is crushed to a paste state, and then taken out for later use.

[0034] 2) enzymolysis: the coconut meat after pulverizing is added 500g water and mixes and makes mixture I, adds the composite enzyme of 2% of mixture I weight, and described composite enzyme is that cellulase and papain are mixed, and described cellulose The mass ratio of enzyme to papain is 1:3, and the enzyme is hydrolyzed in a water bath at 55°C for 48 hours. Inactivate the enzyme at 85°C for 30 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com