Method for preparing water-resistant and weather-resistant bamboo floor by using biochemical modified soybean protein adhesive

A soybean protein glue, soybean protein technology, applied in the direction of protein adhesives, adhesives, wood veneer bonding, etc., can solve the problems of cracking, swelling deformation, unable to meet the needs of users, and achieve hydrophilic base. The effect of reducing the content of agglomerates, increasing the resistance to deformation, and improving the weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

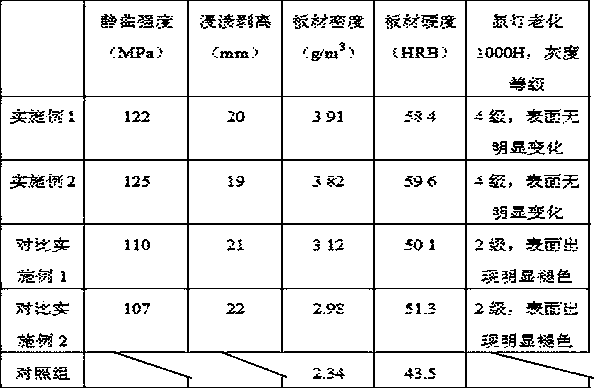

Examples

Embodiment 1

[0025] A method for preparing a water-resistant and weather-resistant bamboo floor with a biochemically modified soybean protein adhesive, comprising the steps of:

[0026] (1) Preparation of environmentally friendly soybean protein adhesive:

[0027] Put the soybean protein hydrolyzate in a constant temperature tank at 34-36°C, adjust the pH to 7.5-8.5, add 2 parts of sodium dodecylbenzenesulfonate under stirring, stir in a constant temperature water bath for 1 hour, then raise the temperature to 50-53°C, add 1 Stir for 13 minutes with 1 part of sodium sulfite, adjust the pH to 7.5-8.5, then raise the temperature to 90-92°C, add 8 parts of polyvinyl alcohol and stir for 25 minutes, add 7 parts of glycerin and stir for 15 minutes, cool and discharge;

[0028] (2) Dipping process:

[0029] Immerse the dried carbonized bamboo into the environmentally friendly soybean protein adhesive obtained in (1), pre-treat the bamboo strips for 15 minutes at a dipping temperature of 34-36°C...

Embodiment 2

[0041] A method for preparing a water-resistant and weather-resistant bamboo floor with a biochemically modified soybean protein adhesive, comprising the steps of:

[0042] (1) Preparation of environmentally friendly soybean protein adhesive:

[0043] Put the soybean protein hydrolyzate in a constant temperature tank at 34-36°C, adjust the pH to 7.5-8.5, add 3 parts of sodium dodecylbenzenesulfonate under stirring, stir in a constant temperature water bath for 2 hours, then raise the temperature to 50-53°C, add 2 Stir with 1 part of sodium sulfite for 13 minutes, adjust the pH to 7.5-8.5, then raise the temperature to 90-92°C, add 9 parts of polyvinyl alcohol and stir for 30 minutes, add 8 parts of glycerin and stir for 20 minutes, cool and discharge;

[0044] (2) Dipping process:

[0045] Immerse the dried carbonized bamboo into the environmentally friendly soybean protein adhesive obtained in (1), pre-treat the bamboo strips at a dipping temperature of 34-36°C for 25 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com