Preparation method of 2-amino-anthraquinone modified graphene oxide cathode material for lithium ion battery

A lithium-ion battery, aminoanthraquinone technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low conductivity and insufficient electrochemical characteristics, and achieve low oxidation degree and good cycle stability. The effect of high degree of resistance and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment prepares AQGO as follows:

[0034] 1. Preparation of sheet-layer graphene oxide

[0035] Mix 2g graphite powder with 1g NaNO 3 Add the powder into a three-necked flask, and then add 50 mL of concentrated H with a mass concentration of 98%. 2 SO 4 , with magnetic stirring in an ice-water bath, 6g KMnO 4 The solid particles were added to the three-necked flask in batches at 5°C, and after the addition was completed, the temperature was raised to 35°C and stirred for 24 hours; after the reaction, 100mL of deionized water was added to the reaction solution, and 250mL of deionized water was added after mixing evenly, and then Add 15mL of 30wt% hydrogen peroxide dropwise to the reaction solution, then add 200mL of 1mol / L HCl solution, stir and mix evenly, then centrifuge at a speed of 4500r / min, remove the supernatant, wash with water and centrifuge the precipitate until the pH is close to neutral. properties; transfer the centrifuged precipitate to a 500m...

Embodiment 2

[0039] In this example, AQGO was prepared by the same method as in Example 1, except that the mass ratio of sheet-layer graphene oxide to 2-aminoanthraquinone in step 2 was 5:1.

Embodiment 3

[0041]In this example, AQGO was prepared according to the same method as in Example 1, except that the mass ratio of sheet-layer graphene oxide to 2-aminoanthraquinone in step 2 was 2:1.

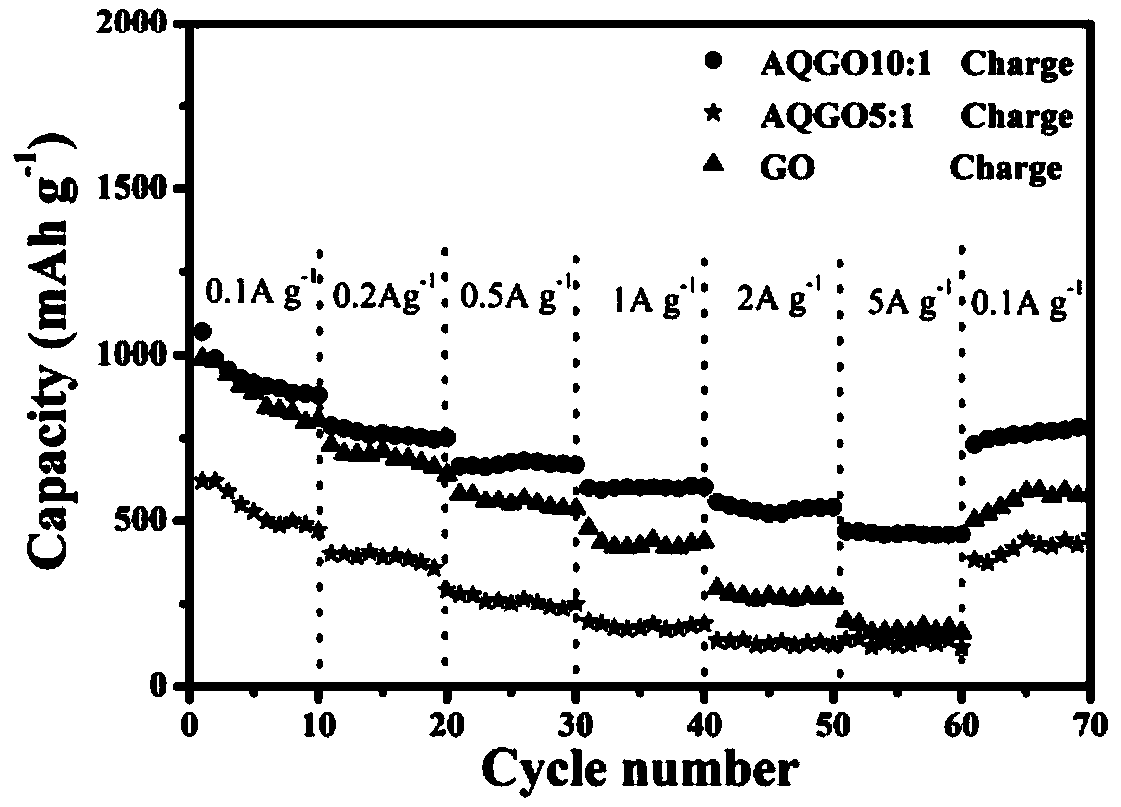

[0042] figure 1 GO and AQGO prepared for the present invention are 0.1Ag at different current densities -1 , 0.2Ag -1 , 0.5Ag -1 , 1Ag -1 , 2Ag -1 and 5Ag -1 The ratio performance comparison chart. in 5Ag -1 Under high current, AQGO 10:1, AQGO 5:1 and GO anode materials still maintain delithiation specific capacities of 471, 192 and 140mAh / g, and have good stability. After 0.1Ag -1 , 0.2Ag -1 , 0.5Ag -1 , 1Ag -1 , 2Ag -1 and 5Ag -1 After the charge-discharge cycle test at the current density, return to the current density of 0.1Ag -1 , AQGO 10:1, AQGO 5:1 and GO anode material delithiation specific capacity can still return to the initial value, reflecting good structural stability.

[0043] figure 2 Transmission electron microscope (TEM) images of GO and AQGO prepared for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com