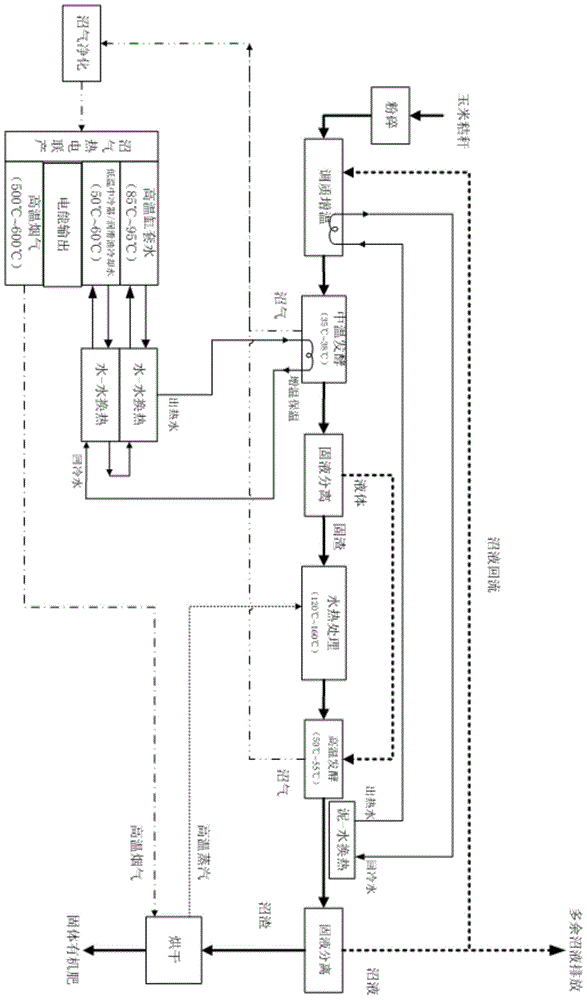

Method for coupling biogas preparation by means of maize straw with power generation waste-heat utilization

A corn stover, biogas power generation technology, applied in fermentation, mechanical equipment, biosynthesis and other directions, can solve the problems of reducing the efficiency of hydrothermal treatment, reducing the direct contact area of steam with refractory cellulose and lignin structures, etc. The effect of preparation efficiency, shortening fermentation cycle and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In July, collect 50 tons of green corn stalks that have just been harvested from green corn (corn in the milk ripening stage). The solid content (TS) of the corn stalks is 20%, and the volatile solid content (VS) is 18%. Diameter ≤ 10mm; add 50 tons of biogas slurry from the solid-liquid separation of the high-temperature fermentation residue at the back end, mix it with corn stalks, adjust the total solid mass percentage of the mixed material to 10%, and the temperature of the mixed material is about 25°C , through mud-water heat exchange to recover the heat of the high-temperature fermentation residue at the rear end, and use the heat in the form of hot water to increase the temperature of the above-mentioned mixed material to 30°C; Fermentation, the heat of cooling water (50°C) and cylinder jacket water (85°C) in the biogas generator set is recovered through water-water heat exchange, and the heat is used in the form of hot water to increase the temperature and heat p...

Embodiment 2

[0041] In September, collect 30 tons of corn stalks that have just harvested dry corn (fully mature corn), the solid content (TS) of corn stalks is 35%, the volatile solid content (VS) is 30%, and it is crushed to a particle size of ≤ 10mm; add 57.5 tons of biogas slurry from the solid-liquid separation of the high-temperature fermentation residue at the back end, mix it with corn stalks, and adjust the total solid mass percentage of the mixed material to 12%. At this time, the temperature of the mixed material is about 20°C. -Water heat exchange recovers the heat from the high-temperature fermentation residue at the back end, and uses the heat in the form of hot water to increase the temperature of the above-mentioned mixture to 28°C; -Water heat exchange recovers the heat of the cooling water (55°C) and cylinder jacket water (90°C) in the biogas generator set, and uses the heat in the form of hot water to increase the temperature of the medium-temperature fermentation materia...

Embodiment 3

[0043] In December, 11 tons of dried corn stalks were collected after being air-dried and stored in the sun. The solid content (TS) of the corn stalks was 90%, and the volatile solid content (VS) was 82%. 55 tons of biogas slurry after the solid-liquid separation of the high-temperature fermentation residue at the back end is mixed with corn stalks, and the total solid mass percentage of the mixed material is adjusted to 15%. At this time, the temperature of the mixed material is about 15°C, and it is recovered through mud-water heat exchange The heat of the high-temperature fermentation residue at the back end is used in the form of hot water to increase the temperature of the above-mentioned mixed material, and the temperature is increased to 25°C; Recover the heat of the cooling water (60°C) and cylinder jacket water (95°C) in the biogas generator set, and use the heat in the form of hot water to increase the temperature and heat preservation of the medium-temperature fermen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com