A system for the production of straw biogas coupled with power generation waste heat utilization

A technology for biogas and generator sets, applied in biochemical equipment and methods, gas production bioreactors, bioreactor/fermenter combinations, etc., can solve the problem of reducing the direct contact area of steam with refractory cellulose and lignin structures, etc. It can shorten the fermentation cycle, improve the efficiency and increase the degree of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

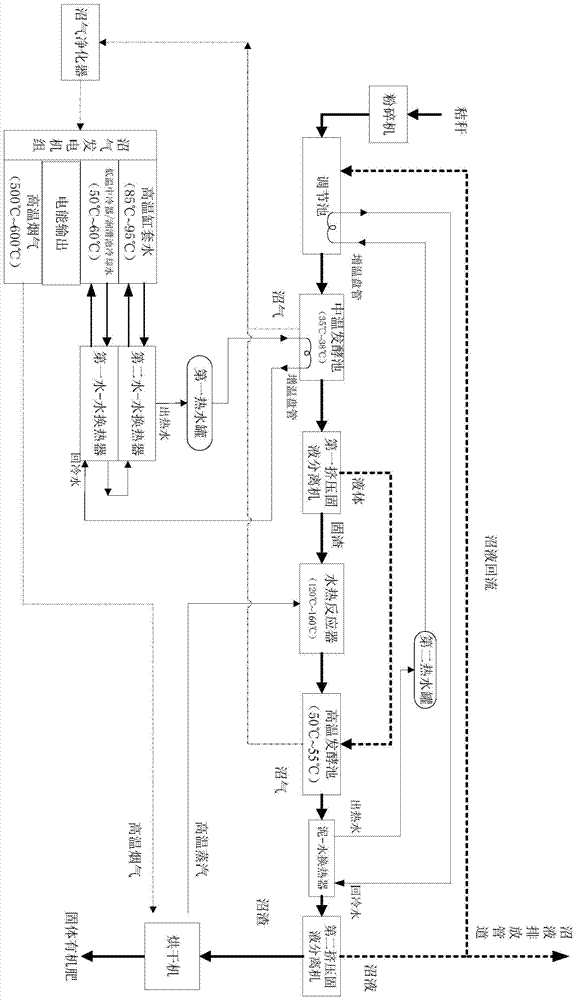

[0015] Such as figure 1 Shown is a schematic diagram of an embodiment of the waste heat utilization system coupled with power generation for straw biogas preparation in the present invention.

[0016] The system for straw biogas preparation coupled with power generation waste heat utilization includes: pulverizer, regulating tank, medium-temperature fermentation tank, first extrusion solid-liquid separator, hydrothermal reactor, high-temperature fermentation tank, second extrusion solid-liquid separator, oven Dryer, biogas purifier, biogas generator set, first water-water heat exchanger, second water-water heat exchanger, first hot water tank, mud-water heat exchanger, second hot water tank; The discharge port of the machine is connected with the feed port of the regulating tank, the discharge port of the regulating tank is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com