Method for treating waste liquid of sweet potato fuel alcohol

A technology for fuel ethanol and waste liquid, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, food industry wastewater treatment, etc. problem, to achieve the effect of good COD removal, good chromaticity and TP removal, and high anaerobic organic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

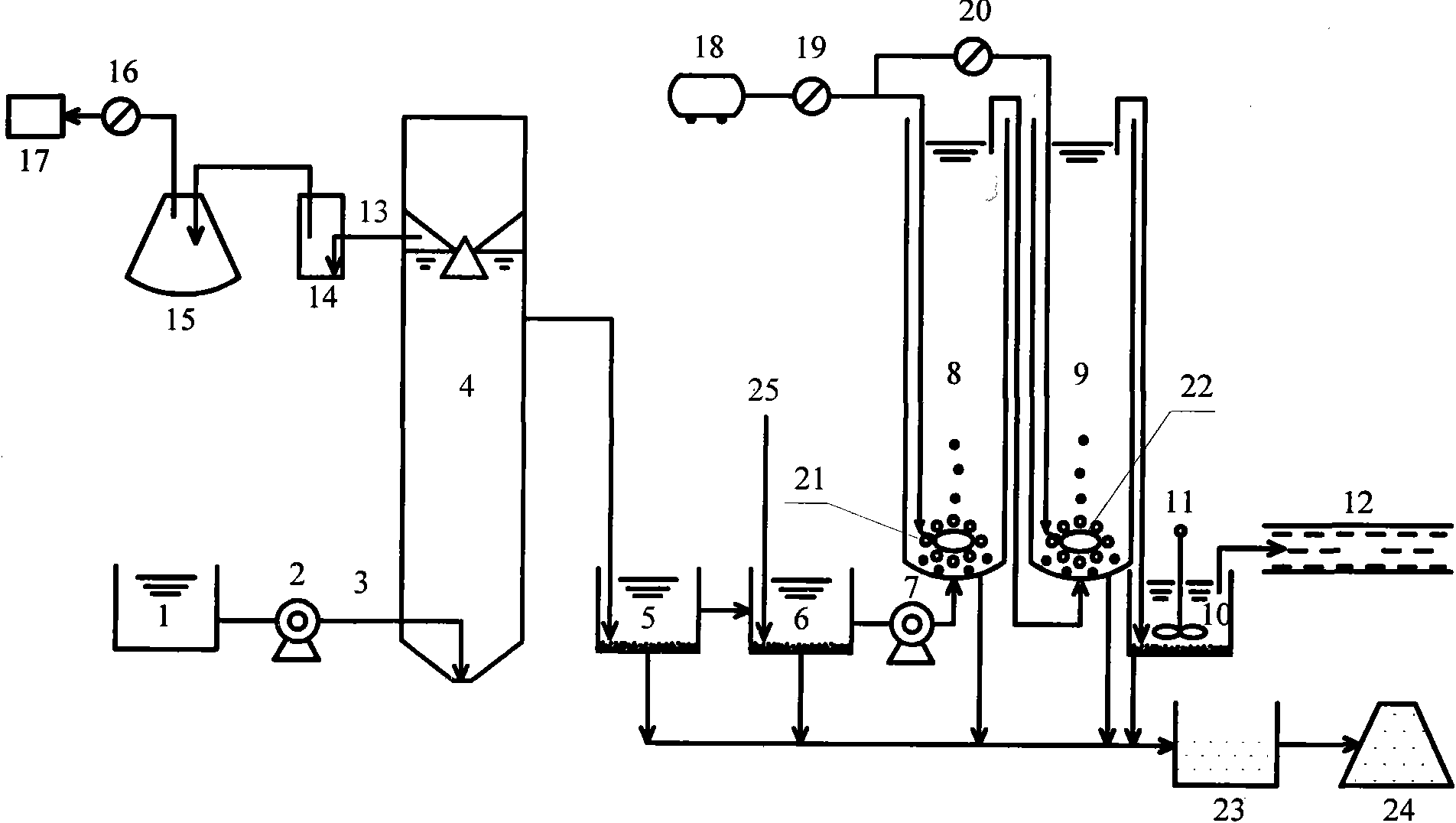

[0019] A. Sequencing batch ASB reactor 4:

[0020] Sequencing batch ASB reactor 4 is reformed from the original UASB reactor. The specification is φ×H=18×120cm, the total volume is 30L, the effective volume is 22.9L, the ratio of height to diameter is 6.67:1, and it is made of PVC pipe. After reforming, the reactor 4 maintains the original water seal, water distributor and air chamber. There are two changes, one is that the original water outlet pipe is changed from the top of the reactor 4 to the bottom of the air chamber, 65cm away from the bottom of the reactor 4, and 55cm away from the top; the other is that the operation mode is changed from continuous water inlet to intermittent sequential batch feeding Water and digestive juice are drained after standing and settling, which is more conducive to the separation of gas, liquid and solid, and can maximize the amount of sludge in the reactor 4.

[0021] B. Sequencing batch ASB reactor 4 start-up and granular sludge cultiva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com