Shell-breaking full-mixing type anaerobic reactor

An anaerobic reactor, fully mixed technology, applied in anaerobic digestion treatment, chemical instruments and methods, special treatment targets, etc., can solve the problem that raw materials and fermentation bacteria cannot be fully mixed, float on the surface of raw material liquid, and biogas is not easy to escape. and other problems, to achieve the effect of improving biogas yield and raw material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] This embodiment discloses a broken-shell full-mix anaerobic reactor.

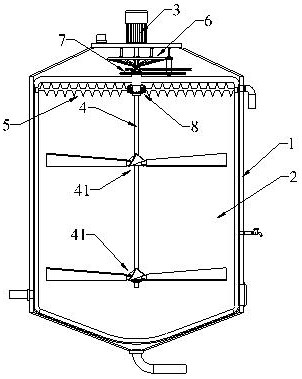

[0043] Such as figure 1 Shown: a broken-shell fully mixed anaerobic reactor, including a cylindrical shell 1 with a reaction chamber 2, a stirring shaft 4 vertically arranged in the reaction chamber 2 along the central axis of the shell 1, and a driving shaft 4 for driving The driving device 3 for rotating the stirring shaft 4; two groups of stirring paddles 41 are arranged at intervals along the central axis on the stirring shaft 4 .

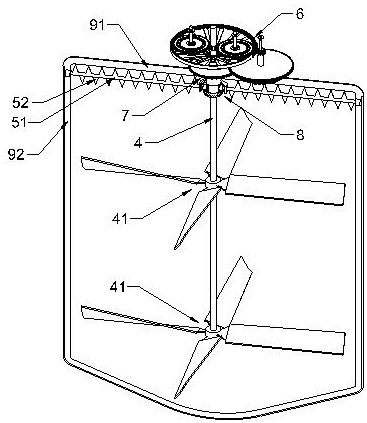

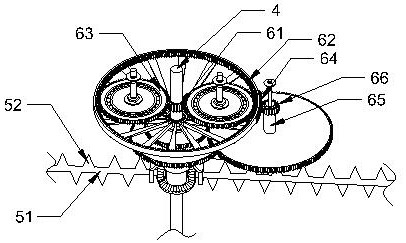

[0044] combine figure 2As shown: the shell-breaking full-mix anaerobic reactor of this embodiment also includes a shell-breaking mechanism 5 arranged in the reaction chamber 2, and a horizontal transmission mechanism 7 and a longitudinal transmission mechanism 8 respectively connected to the stirring shaft 4; The shell mechanism 5 includes a shell-breaking beam 51 transversely arranged in the reaction chamber 2, and a shell-breaking assembly arranged on the shell-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com