Plasma processing device and method

A plasma and processing device technology, applied in the field of semiconductor manufacturing and ion processing device internal cleaning, can solve the problems of reducing equipment cleaning efficiency, difficult to ensure consistent substrate process environment, poor component cleaning effect, etc., to ensure cleaning effect, The effect of avoiding discharge and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. The technology disclosed in the present invention is applicable to various plasma processing devices, especially suitable for capacitively coupled plasma processing devices.

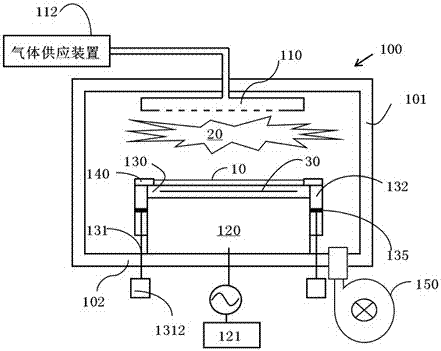

[0027] figure 1 A schematic structural diagram of an ion plasma treatment device applicable to the method of the present invention is shown. In this embodiment, the plasma processing device is a capacitively coupled plasma processing device, and the capacitively coupled plasma processing device includes a reaction chamber 100, and the reaction chamber includes a substantially cylindrical reaction chamber side wall made of a metal material 101 and the reaction chamber bottom wall 102, the reaction chamber side wall 101 and the reaction chamber bottom wall 102 and the reaction chamber upper wall form a reaction chamber structure that can be vacuumed, and an upper electrode 110 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com