Method for preparing milk gel

A gel and casein technology, applied in the direction of bacteria and lactobacilli used in dairy products and food preparation, can solve the problems of protein milk gel cold gel easy to separate water and other problems, to achieve good water retention and easy dissolution , The effect of high-quality gel network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0057]Embodiment 3, embodiment 4 and embodiment 5 adopt simulated ultrafiltrate to prepare casein solution, contain dipotassium hydrogen phosphate 1.6g, potassium citrate 1g, sodium citrate 2g, potassium sulfate 0.3g in every kilogram of this simulated ultrafiltrate g, calcium chloride 1.2g, magnesium chloride 0.8g, potassium carbonate 0.4g, potassium chloride 0.5g, and the rest are deionized water. Using transglutaminase (TG enzyme, enzyme activity is 200u / g).

Embodiment 1

[0059] This example provides a method for preparing milk gel.

[0060] The raw materials used include:

[0061] Milk 973g, potassium phosphate 10g, transglutaminase 2g, glucuronolactone 15g.

[0062] The specific preparation steps include,

[0063] The milk is homogenized, the homogenization temperature is 50°C, and the homogenization pressure is 20MPa.

[0064] After the homogenized casein solution was cooled to room temperature, potassium phosphate was added, stirred for 10 minutes, and allowed to stand for 10 minutes.

[0065] Add transglutaminase to the above solution, and cross-link in a water bath at 40-45° C. for 3 hours.

[0066] Cool the obtained solution to 4-10°C, add glucuronolactone, control the feeding speed at 1-2g / min, then place it at 35-45°C for 4-6 hours, and cool to 4-10°C.

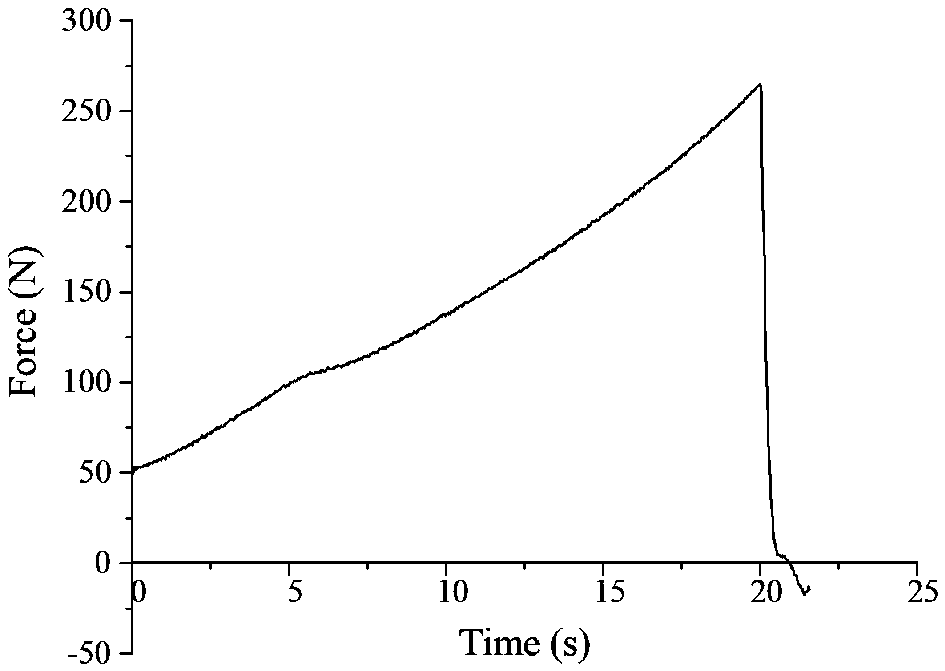

[0067] The strength of the milk gel obtained in this embodiment is 265mN.

Embodiment 2

[0069] This example provides a method for preparing milk gel.

[0070] The raw materials used include:

[0071] Milk 984.5g, potassium phosphate 3g, transglutaminase 0.5g, glucuronolactone 12g.

[0072] The specific preparation steps include,

[0073] The milk is homogenized, the homogenization temperature is 55°C, and the homogenization pressure is 40MPa.

[0074] After the homogenized casein solution was cooled to 30°C, potassium phosphate was added, stirred for 15 minutes, and left to stand for 10 minutes.

[0075] Add transglutaminase to the above solution, and cross-link in a water bath at 40-45° C. for 2 hours.

[0076] Cool the obtained solution to 4-10°C, add glucuronolactone, control the feeding speed at 1-2g / min, then place it at 35-45°C for 4-6 hours, and cool to 4-10°C.

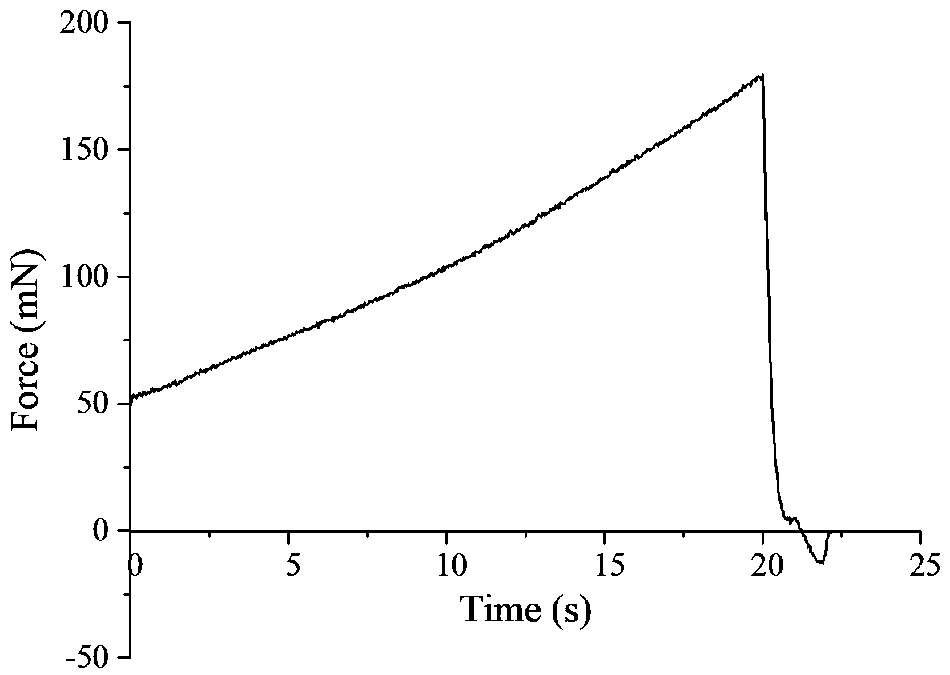

[0077] The strength of the milk gel obtained in this embodiment is 179mN.

[0078] Example 3

[0079] This example provides a method for preparing milk gel.

[0080] The raw materials used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com