Process for manufacturing lithium sulfur battery

A lithium-sulfur battery and manufacturing process technology, which is applied in electrode manufacturing, sustainable manufacturing/processing, secondary batteries, etc., can solve problems such as poor electrical conductivity and limited ability to adsorb active material sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

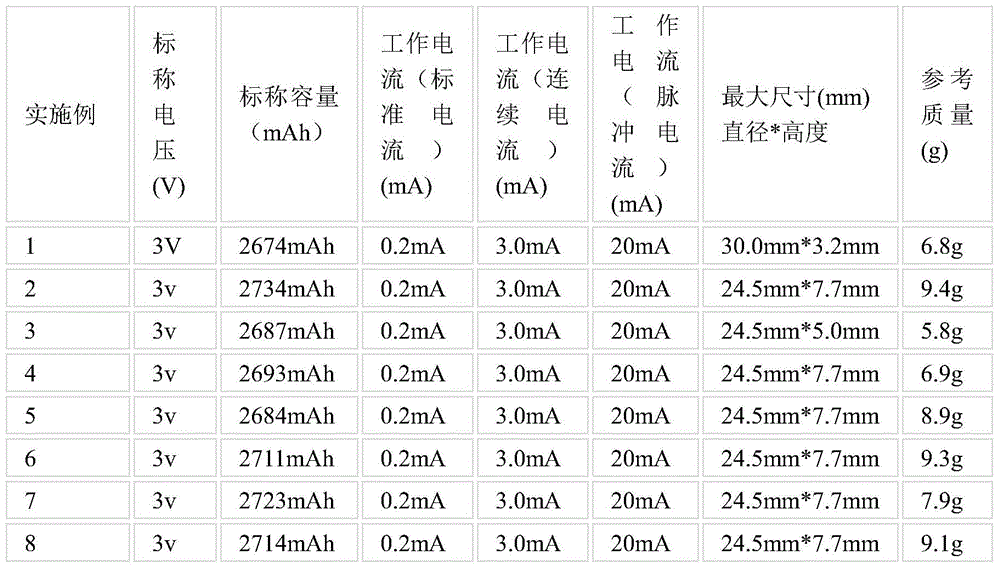

Examples

Embodiment 1

[0053] In a 1L 316L stainless steel reaction kettle, under the protection of continuously feeding 160ml / min nitrogen, add 5.6mol industrial superior grade NMP, 1.0mol industrial superior grade sodium sulfide and 0.001mol industrial superior grade sodium hydroxide, and stir at 690rpm Slowly raise the temperature of the reaction system to 138°C, then add 1.003mol of industrial grade lithium chloride, continue to raise the temperature of the reaction system to 160°C, and keep the reaction system at this temperature for 9 minutes, When fine white crystals are precipitated in the reaction system, evaporate and remove the water in the reaction system at the same time, and stop heating; filter while hot, filter out the white crystals in the reaction system, add the filtrate to the reaction system again, Stirring intensity is 160rpm, add sublimated sulfur of 4mol / mol lithium sulfide and deionized oxygen-free water, wait until the temperature rises to 138°C, and keep it under reflux for...

Embodiment 2

[0059] In a 1L 316L stainless steel reaction kettle, under the protection of continuously feeding 690ml / min nitrogen, add 6.6mol industrial superior grade NMP, 1.0mol industrial superior grade sodium sulfide and 0.001mol industrial superior grade sodium hydroxide, and stir at 690rpm Slowly raise the temperature of the reaction system to 148°C, then add 1.003mol of industrial grade lithium chloride, continue to raise the temperature of the reaction system to 190°C, and keep the reaction system warm for 6min under this temperature condition, When fine white crystals are precipitated in the reaction system, evaporate and remove the water in the reaction system at the same time, and stop heating; filter while hot, filter out the white crystals in the reaction system, add the filtrate to the reaction system again, The stirring intensity is 690rpm, add 8mol / mol lithium sulfide sublimated sulfur and deionized anaerobic water, wait for the temperature to rise to 148°C, and keep it unde...

Embodiment 3

[0064] In a 1L 316L stainless steel reaction kettle, under the protection of continuously feeding 261ml / min nitrogen, add 5.8mol industrial superior grade NMP, 1.0mol industrial superior grade sodium sulfide and 0.001mol industrial superior grade sodium hydroxide, and stir at 234rpm Slowly raise the temperature of the reaction system to 139°C, then add 1.003mol of industrial superior lithium chloride, continue to raise the temperature of the reaction system to 163°C, and keep the reaction system warm for 7min under this temperature condition, When fine white crystals are precipitated in the reaction system, evaporate and remove the water in the reaction system at the same time, and stop heating; filter while hot, filter out the white crystals in the reaction system, add the filtrate to the reaction system again, The stirring intensity is 234rpm, add 5mol / mol lithium sulfide sublimated sulfur and deionized anaerobic water, wait until the temperature rises to 139°C, and keep it u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com