Patents

Literature

55results about How to "No cleaning required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

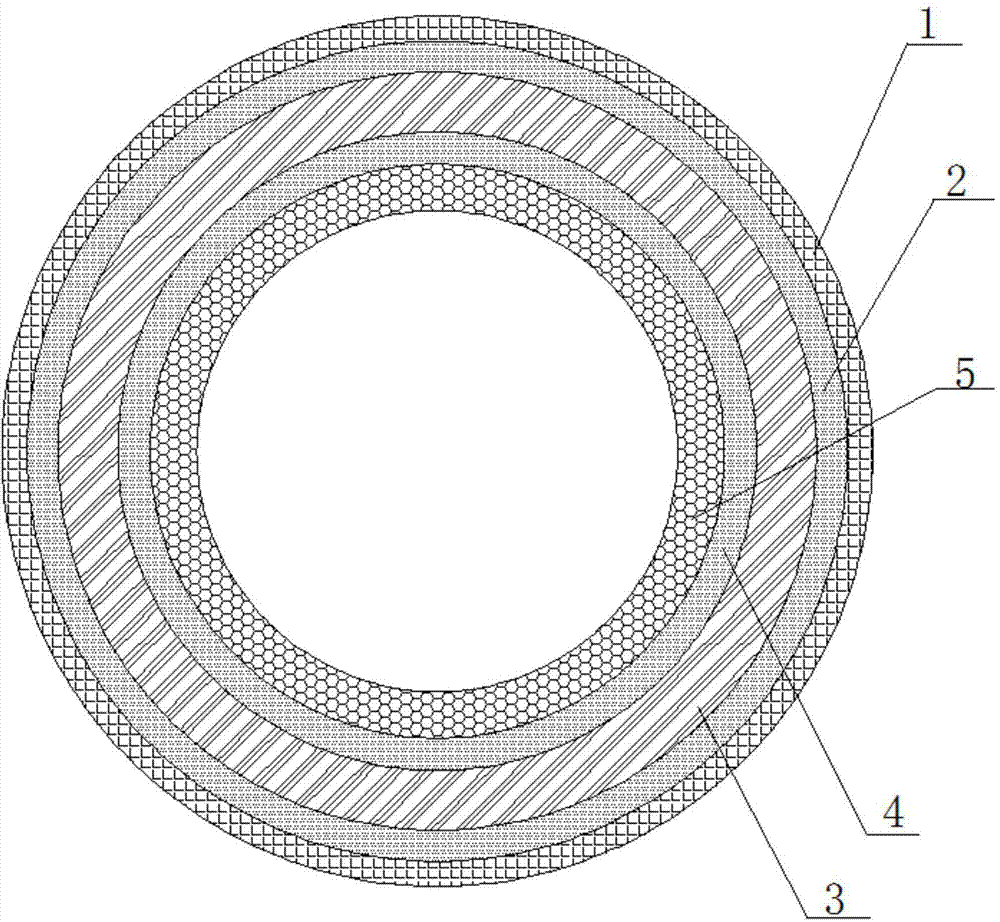

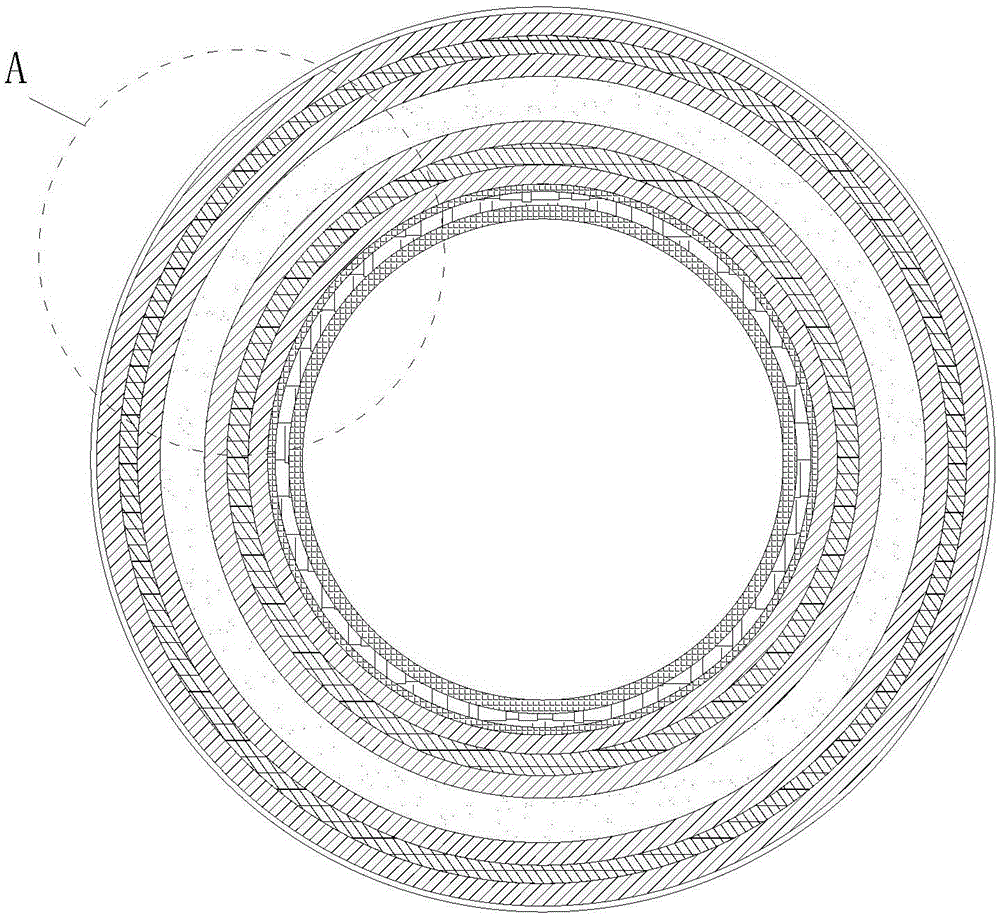

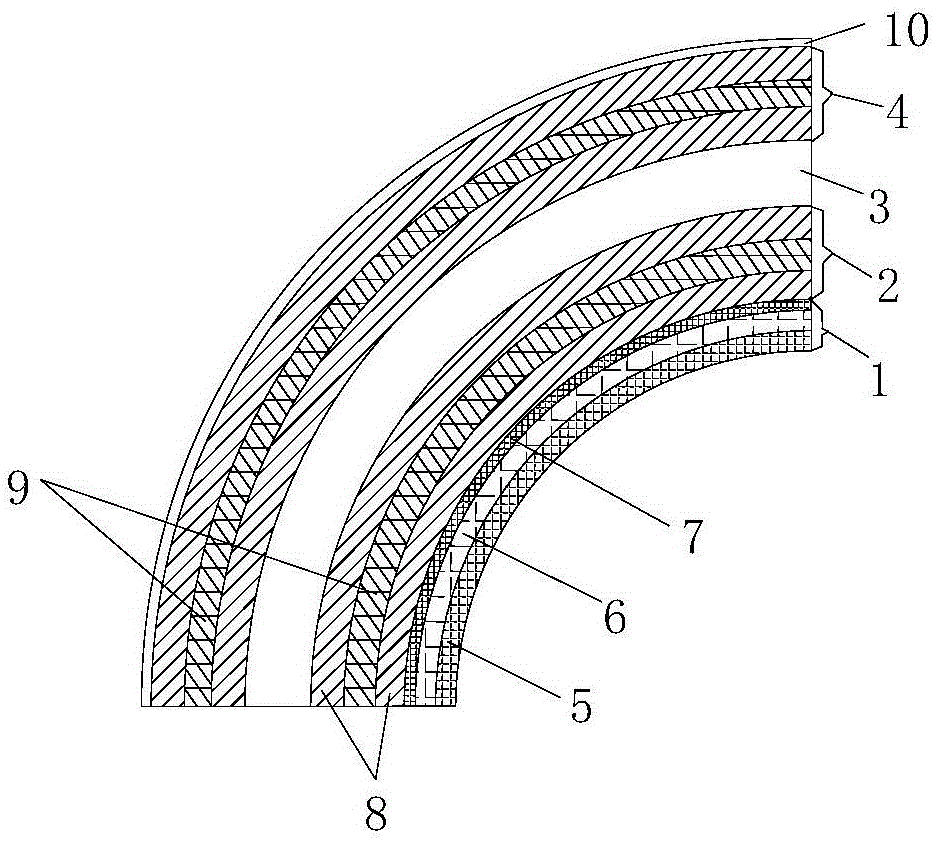

High-strength glass fiber-reinforced plastic pipeline and production method thereof

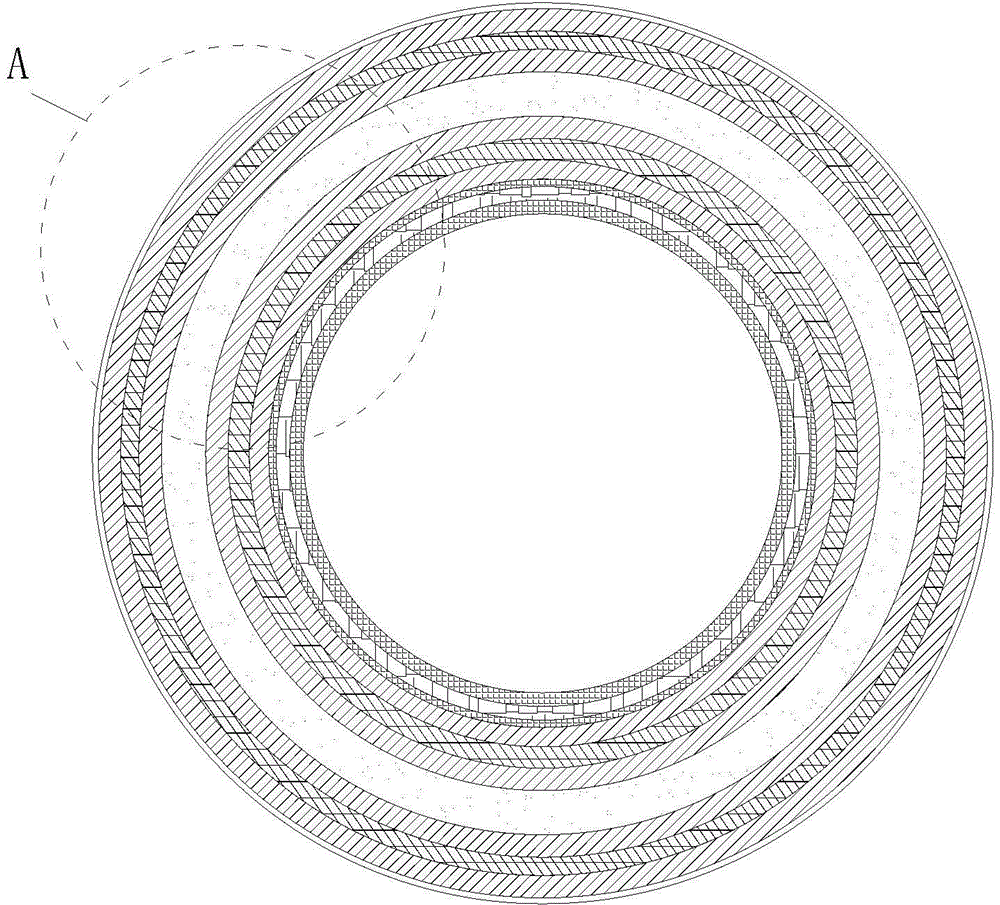

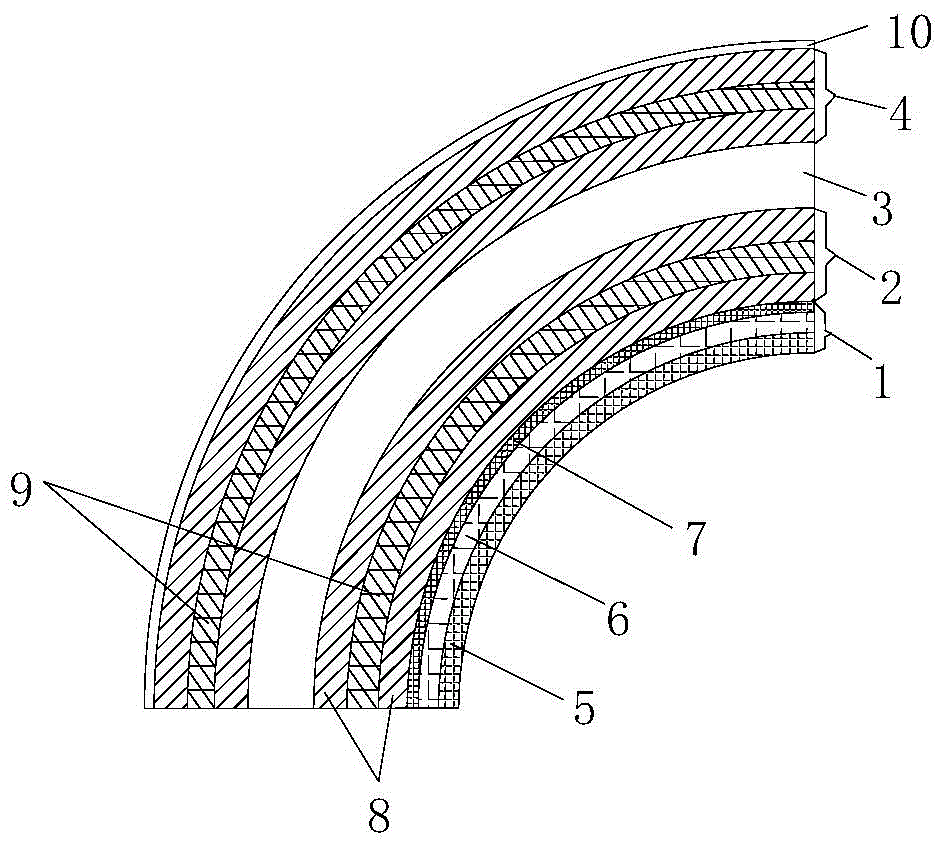

The invention discloses a high-strength glass fiber reinforced plastic pipeline and a production method thereof, and belongs to the technical field of glass fiber reinforced plastic pipelines and production methods thereof. The high-strength glass fiber reinforced plastic pipeline is a circular pipeline, and is characterized by comprising a lining layer, an inner structural layer, a middle sand inclusion layer and an outer structural layer, wherein the lining layer is formed by soaking and bonding a glass fiber surface felt layer, a glass fiber knitted felt layer and a grid cloth layer in sequence through lining resin from inside to outside; the inner structural layer and the outer structural layer are constructed by one or more glass fiber yarn annular winding layers and one or more glass fiber yarn crossed winding layers; the annular winding layers and the crossed winding layers are formed at intervals; the middle sand inclusion layer consists of upper layer sand inclusion cloth, lower layer sand inclusion cloth and a sand material compressed and clamped between the upper layer sand inclusion cloth and the lower layer sand inclusion cloth; the sand material is formed by mixing quartz sand and sand adhesion resin. The pipeline has the advantages of high compressive strength, high axial tensile strength, large pipe diameter span, light weight, high hydraulic performance, freeness from scaling, insulation, flame retardance and corrosion resistance.

Owner:HUNAN XIAOXIANGYUAN TECH DEV

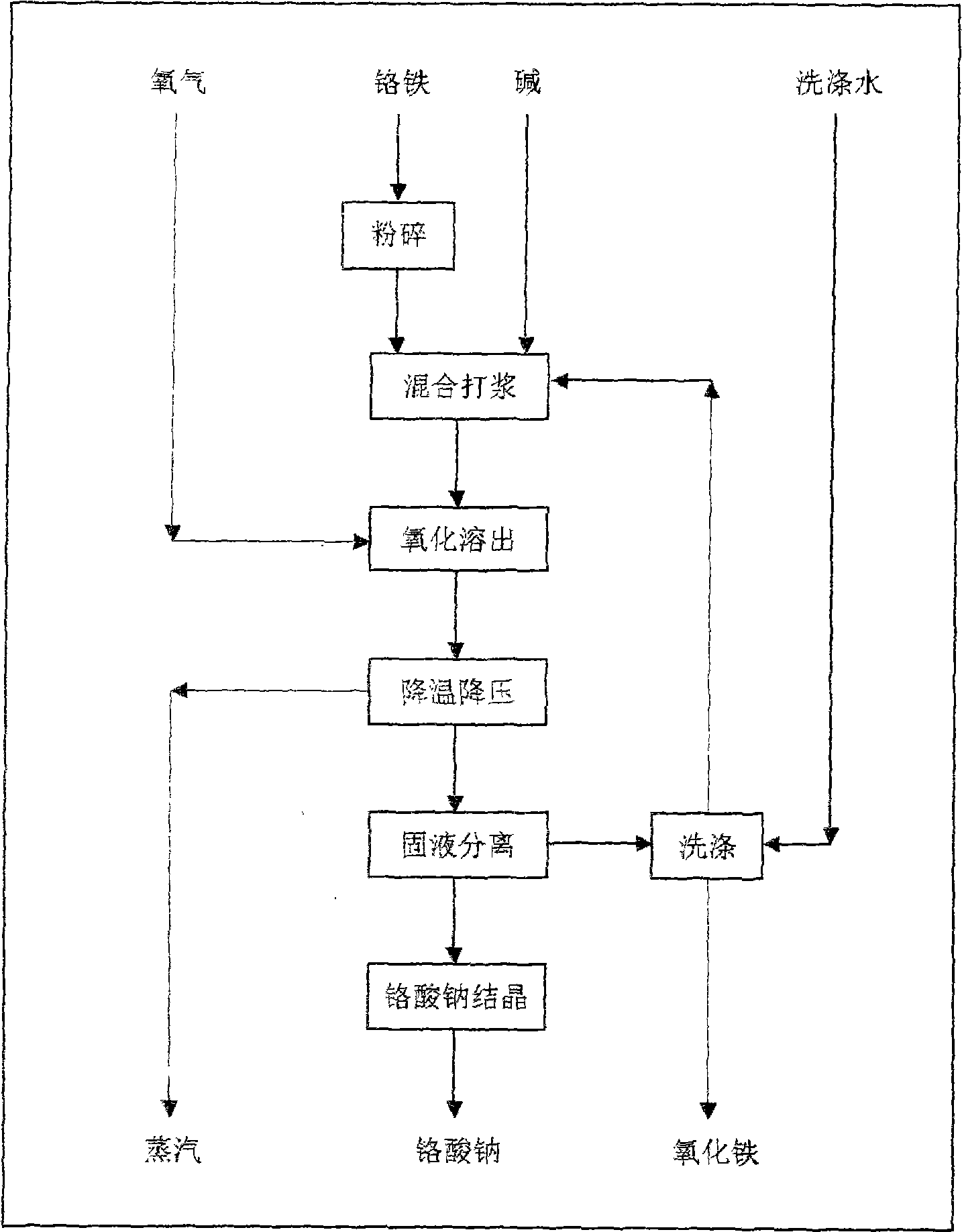

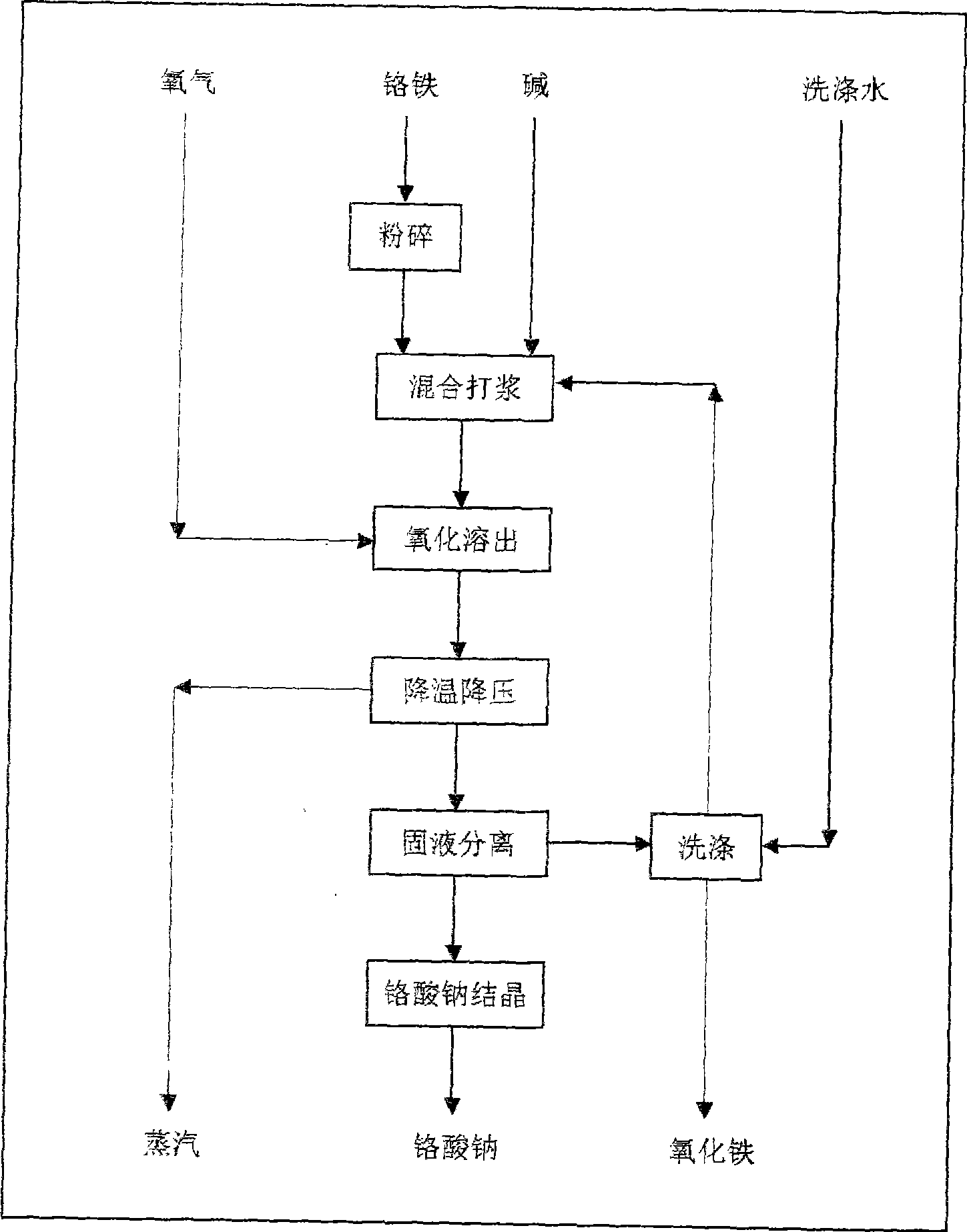

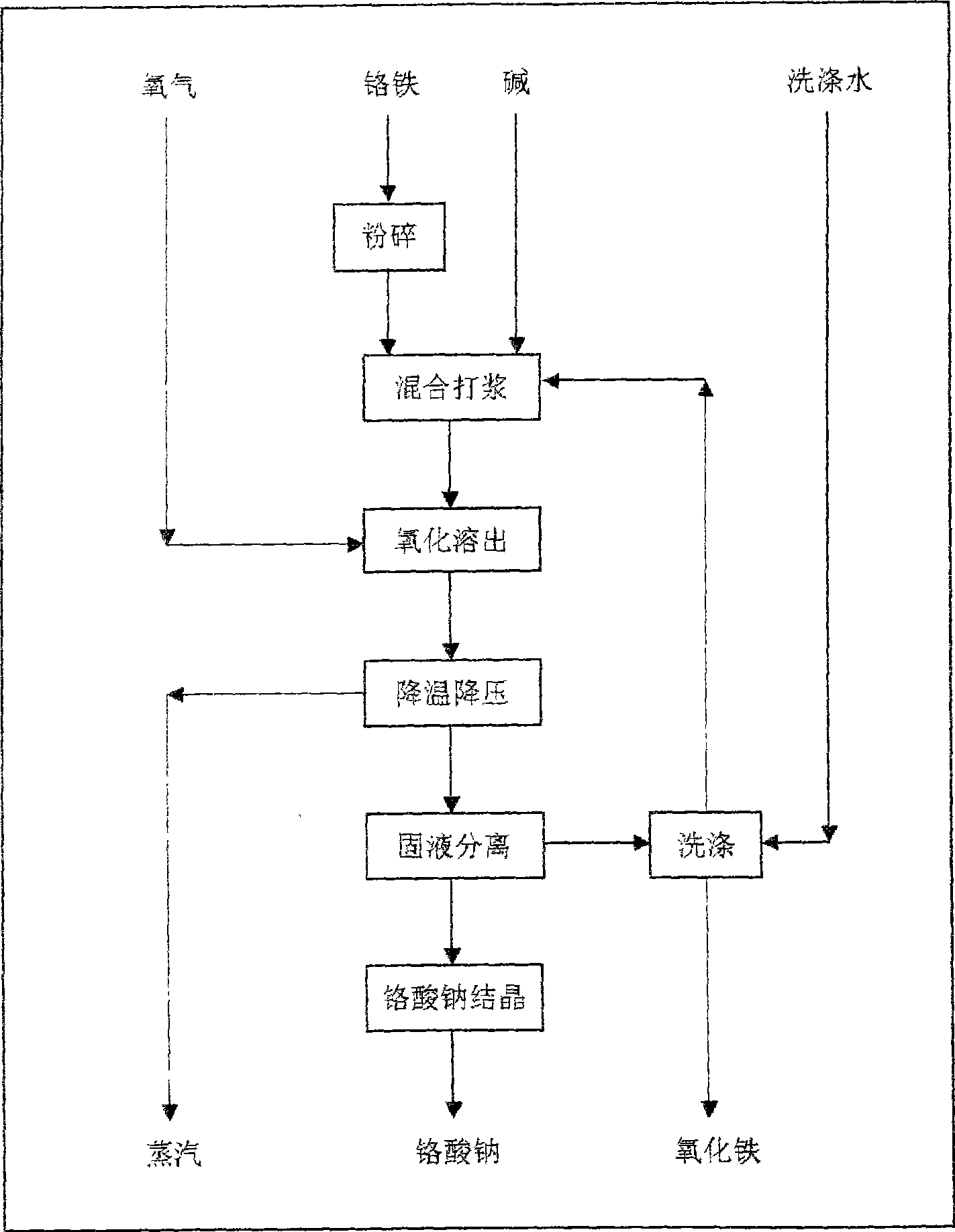

High-efficiency, energy-conservation and clean method for producing chromate

ActiveCN101508466ASolve pollutionAchieving the purpose of cleaner productionChromates/bichromatesWastewaterCleaning methods

The invention provides a method for producing chromate with high efficiency, energy conservation and cleanness. The method uses chromium iron as a raw material, and carries out oxidation dissolution in high-temperature high-pressure aqueous alkali to separate solid and liquid after temperature and pressure reduction so as to obtain a chromate solution, water and ferric oxide or mixture of the water, ferric oxide and chrome oxide. A high-temperature high-pressure reactor is used as the reactor of the method so as to greatly improve equipment efficiency and production efficiency. The method realizes autothermal reaction by system reaction heat to achieve the aim of energy conservation, and is an energy-saving process of chromate production. The method does not need external fuel to supply heating and does not generate waste gas, and the reaction precipitate is the water and the ferric oxide or the mixture of the water, the ferric oxide and the chrome oxide, wherein the water and the ferric oxide or the mixture of the water, the ferric oxide and the chrome oxide can be used for preparing chromium iron paint without generating waste residue; and washing of the precipitate adopts countercurrent washing, and washing water is used for preparing a reaction initial solution without generating waste water. The method does not generate the three wastes, and is a clean process for producing the chromate.

Owner:青海省博鸿化工科技股份有限公司

Repairing material for base layer of oil colored paintings of ancient architecture and preparation technology thereof

InactiveCN101831127AImprove mechanical stabilityImprove freeze-thaw stabilityCovering/liningsBuilding repairsFreeze thawingAdhesive

The invention discloses a repairing material for a base layer of oil colored paintings of ancient architecture, which comprises an acrylic acid-2-ethylhexyl ester, a vinyl acetate, a methyl methacrylate, an acrylic acid, an N-hydroxymethyl acrylamide, an emulsifying agent, a neutralizing agent, a defoaming agent, a rheological agent and an initiating agent. The preparation technology comprises the following steps of: preparing a polyacrylate emulsion by using free radical emulsion polymerization, and adding the neutralizing agent, the deforming agent and the rheological agent in the polyacrylate emulsion to obtain an emulsion binder. The emulsion binder prepared by the invention has no granular condensation products, good mechanical stability, freeze thaw stability and interface adhesion force, can be coated and injected, is free from ash removal and reversible at a high temperature and is applicable to the binding materials for repairing the base layer of the oil colored paintings of the ancient architecture.

Owner:NORTHWEST UNIV(CN)

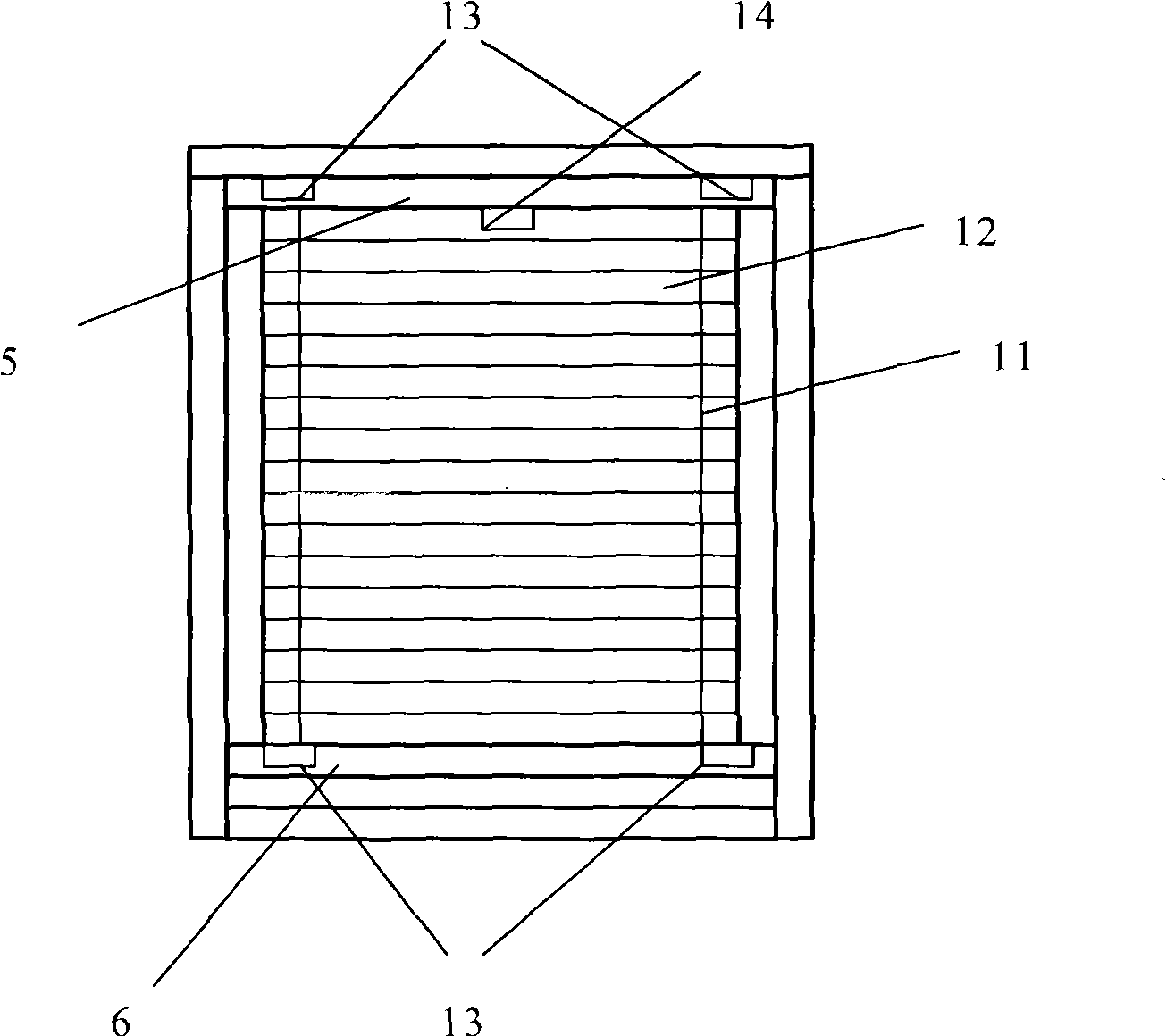

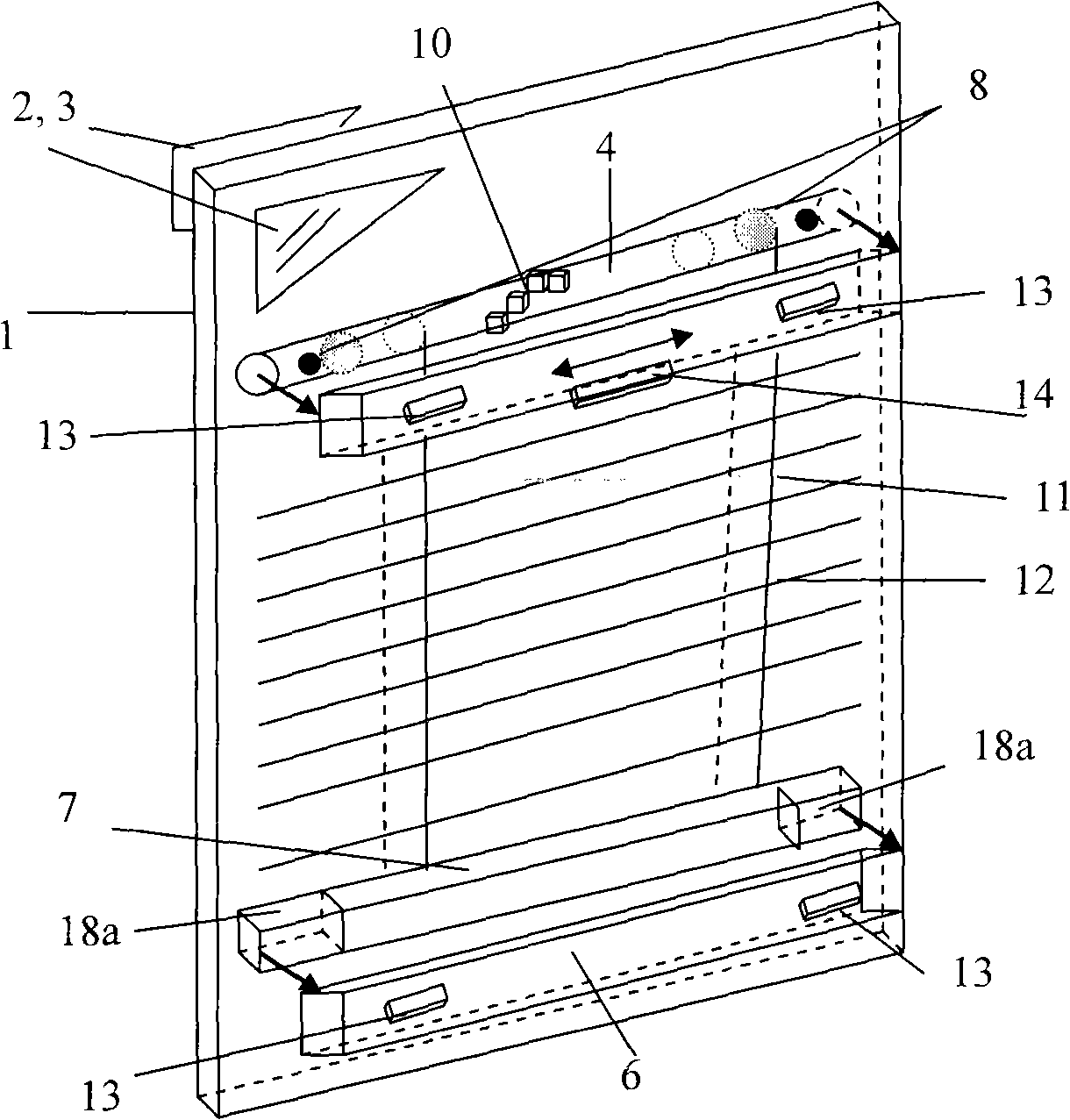

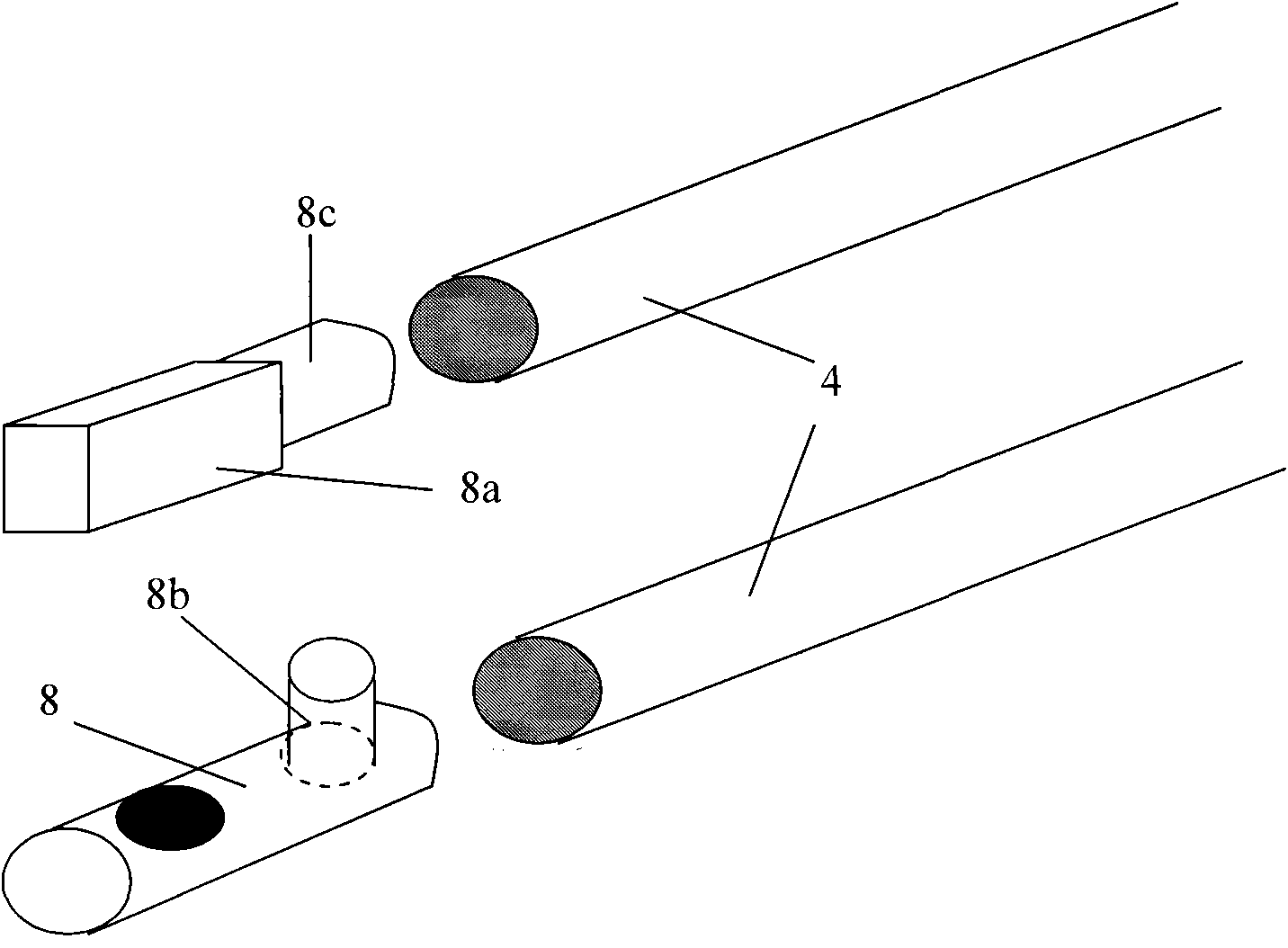

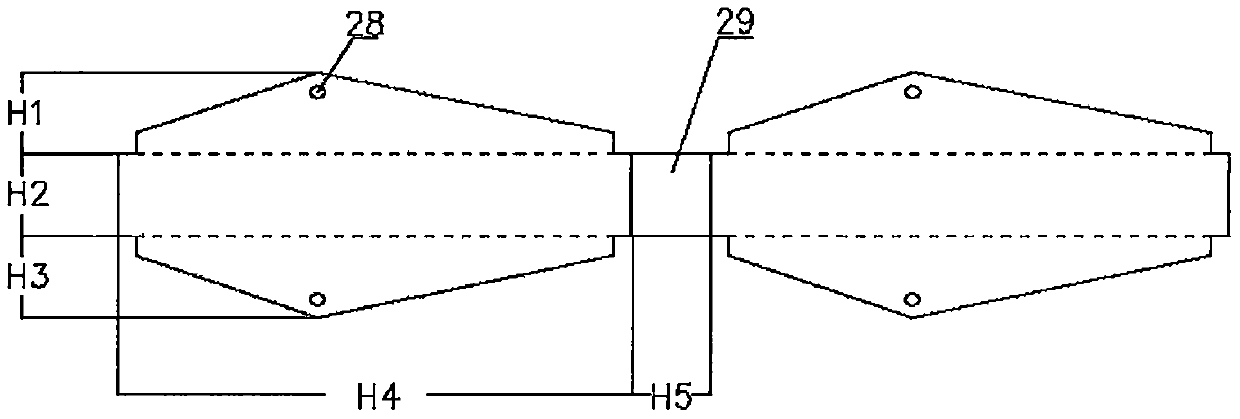

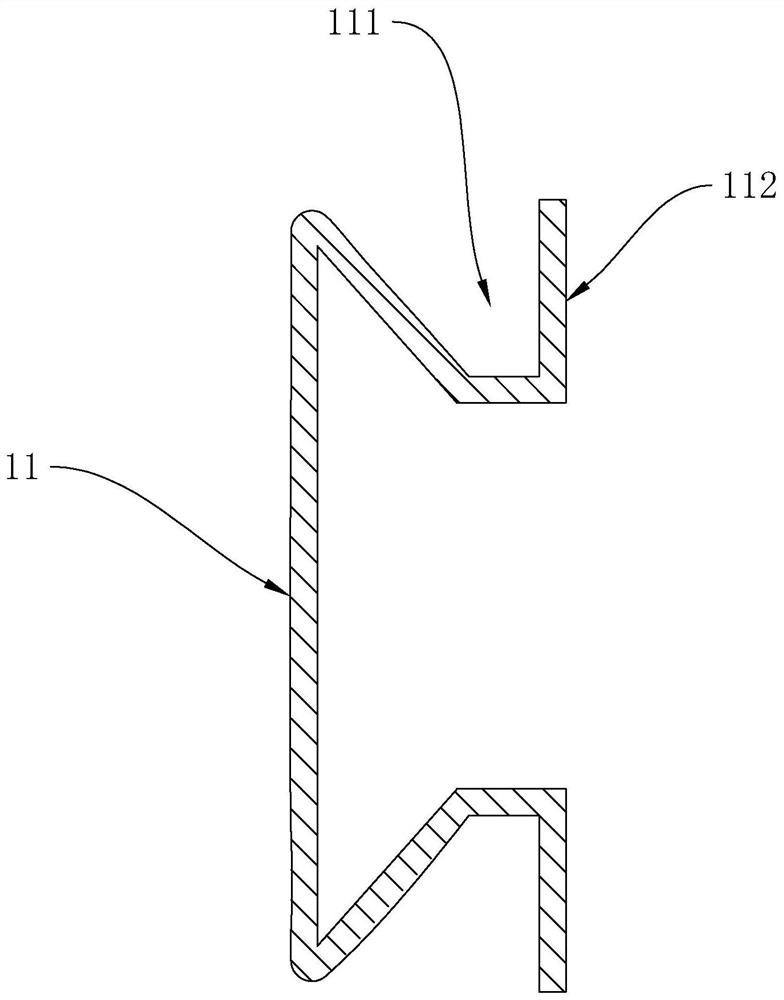

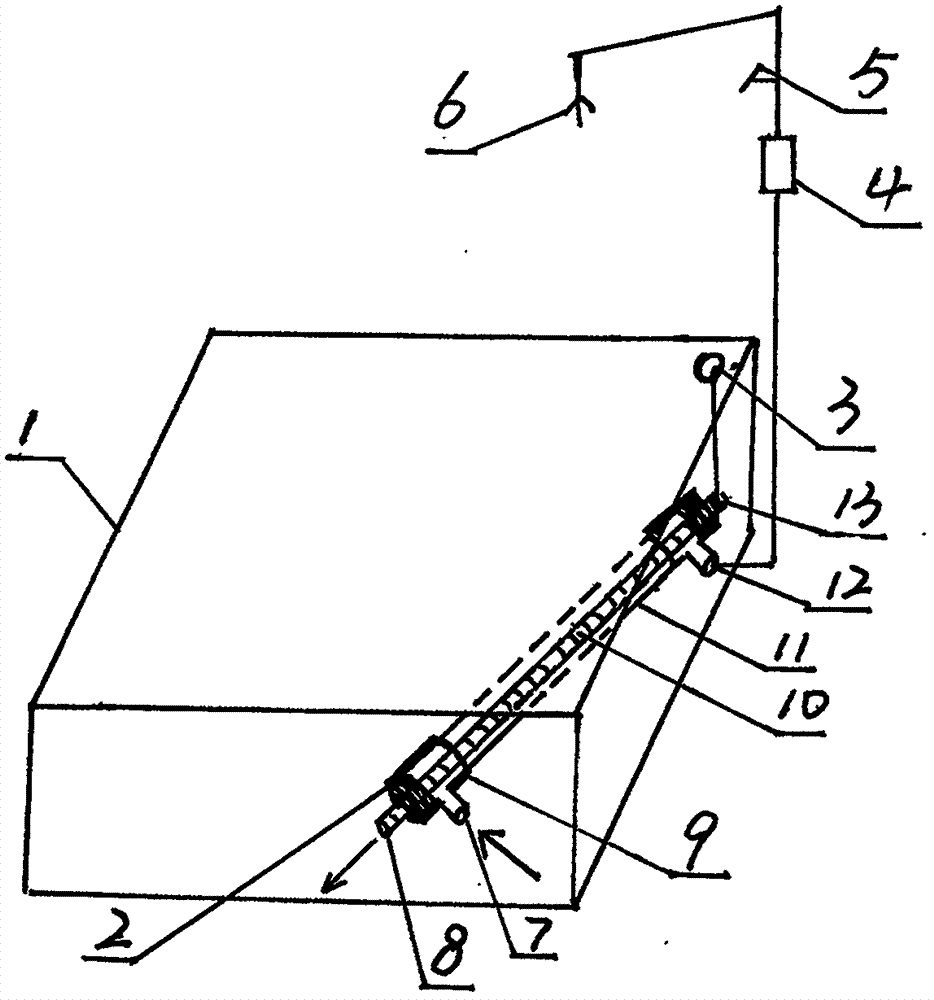

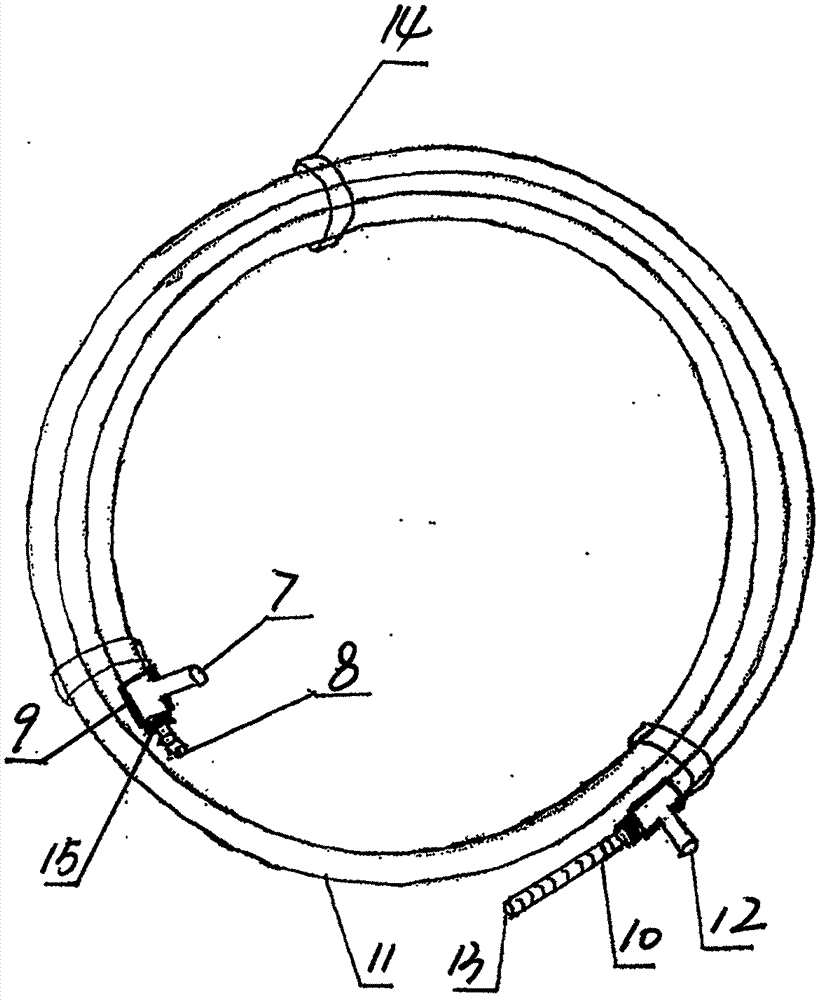

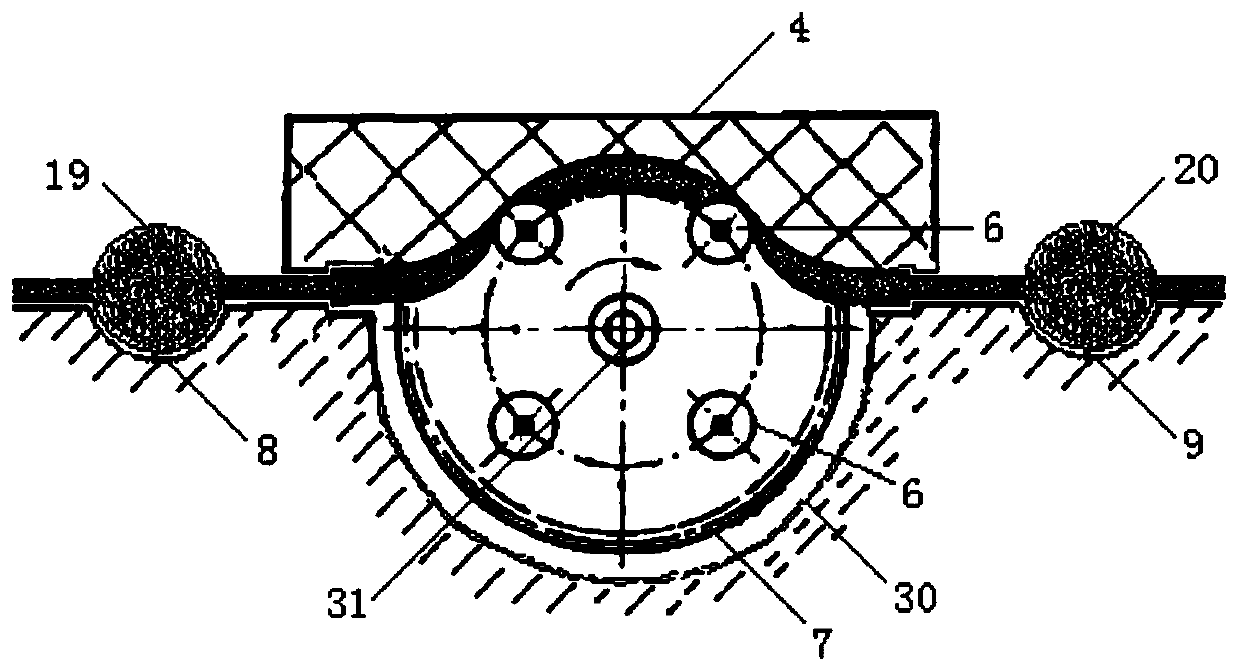

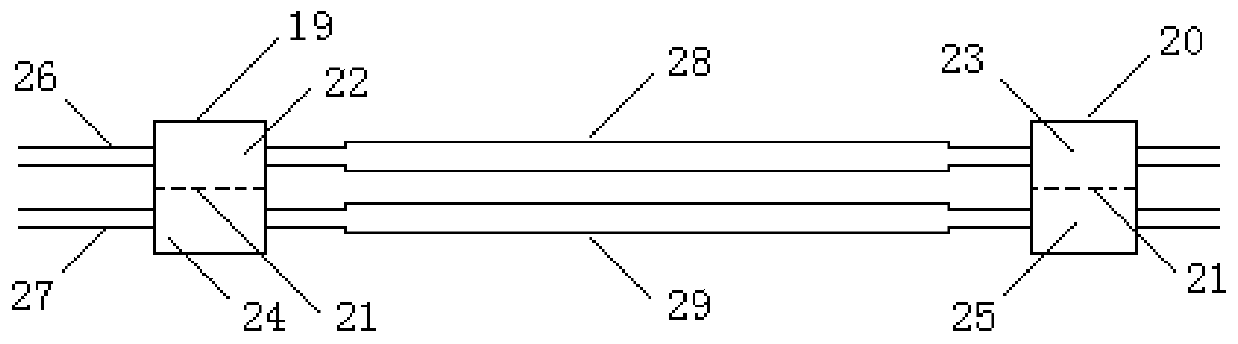

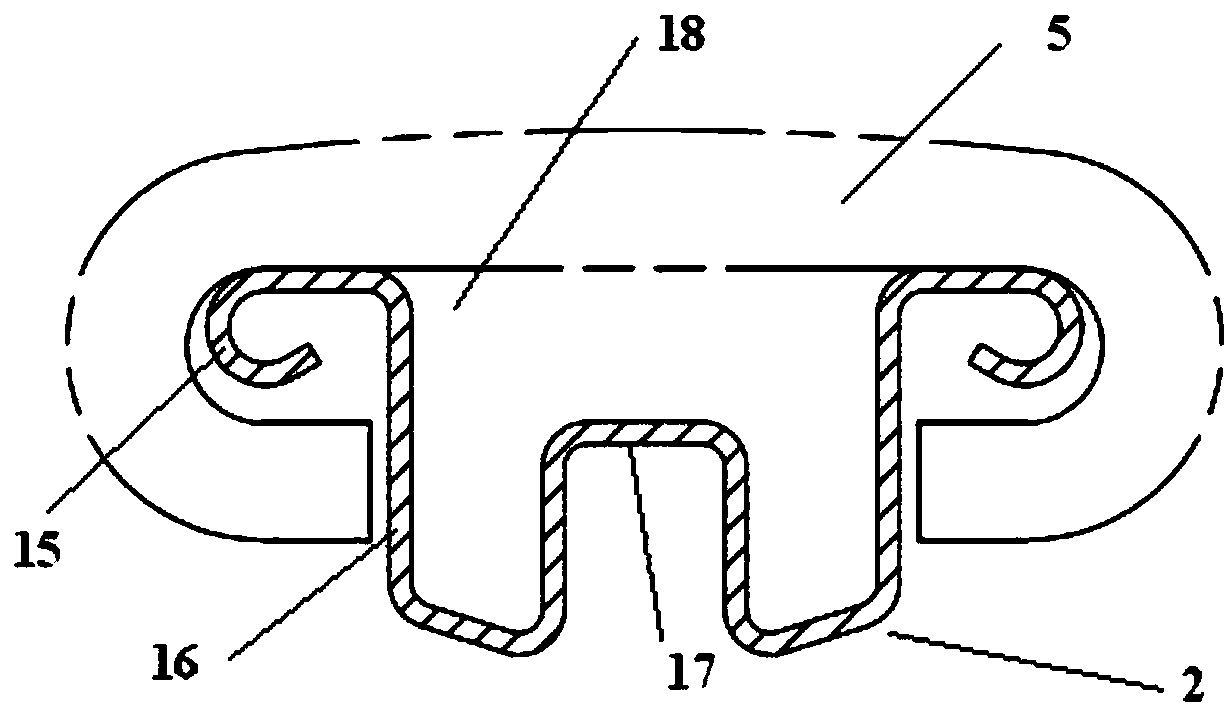

Venetian blinds with magnetic controller for regulation

InactiveCN101550802ANo cleaning requiredEasy to installLight protection screensVenetian blindsRotation control

A Venetian blinds with magnetic controller for regulation consists of strings which form ladder (11) which hold the horizontally fitted slats (12) at the appropriate distance. This structure hangs on the freely rotating bearing hollow pipe (4), and at the bottom it is connected to the inner bottom section (7). Each magnet (8b) in the bearings (8) or the inner top / bottom contact magnets (8a; 18 a) are fitted to be in the opposite magnet pole in relation to the poles of the external top / bottom contact magnets (18; 18b) on the external top and bottom regulating batten (5; 6) Magnets which glide horizontally along the external top regulating batten (5) attract magnets fitted at the edges of the freely rotating bearing hollow pipe (4). The rotation controller (23a; 23b) enables rotation of the slats (12) for 180 DEG . By moving the bottom / top external regulating batten (6; 5) together with the related magnets it is possible to move the Venetian blind up or down, including moving of only one side of the top / bottom regulating batten (6;5). Therefore, interaction of the mentioned elements of the invention it is possible to shade any part of the window, including shading diagonally along the window, which will be described in detail later.

Owner:彭哲彦 +1

Glass fiber-reinforced plastic polyurethane TPU composite tube and manufacturing process thereof

InactiveCN104847977AExtended service lifeReduced operating and maintenance costsThermal insulationFlexible pipesPolyesterCorrosion resistant

The invention discloses a glass fiber-reinforced plastic polyurethane TPU composite tube. The glass fiber-reinforced plastic polyurethane TPU composite tube comprises an outer protective layer, an outer reinforcing layer, a sand inclusion structure layer, an inner reinforcing layer and a lining layer which are sequentially arranged from outside to inside, wherein the outer protective layer is a composite layer with quartz sand and unsaturated polyester resin, the outer reinforcing layer is a composite layer with glass fibers and unsaturated polyester resin, the sand inclusion structure layer is a composite layer with quartz sand, glass fibers and unsaturated polyester resin, the inner reinforcing layer is a composite layer with glass fibers and unsaturated polyester resin, and the lining layer is a low free nanometer polyester layer. The invention further discloses a manufacturing process of the glass fiber-reinforced plastic polyurethane TPU composite tube. The glass fiber-reinforced plastic polyurethane TPU composite tube has reliability, safety and economy, is mainly used for pulp conveying, bittern conveying, sea water desalination and corrosion-resistant and abrasion-resistant process pipelines, has the advantages of being light, high in strength, resistant to corrosion, high in abrasion resistance, long in service life, low in operation and maintenance cost and the like, and saves a large number of expenses for construction engineering.

Owner:张俊达 +1

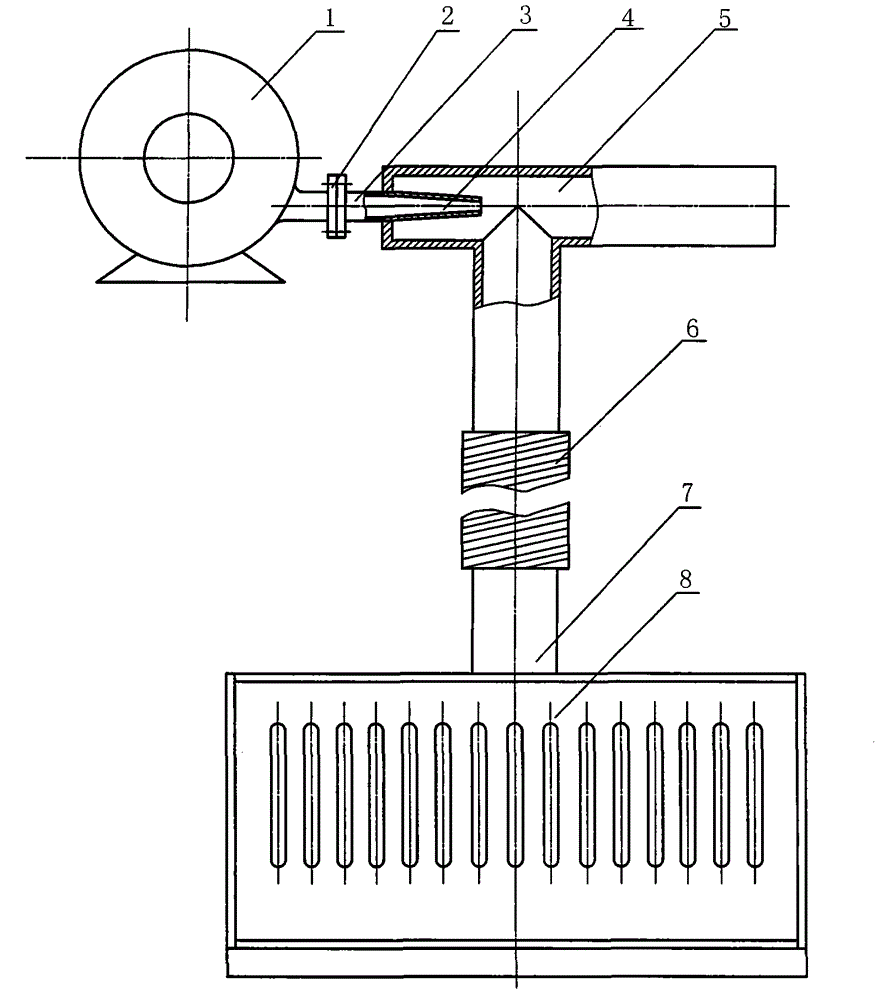

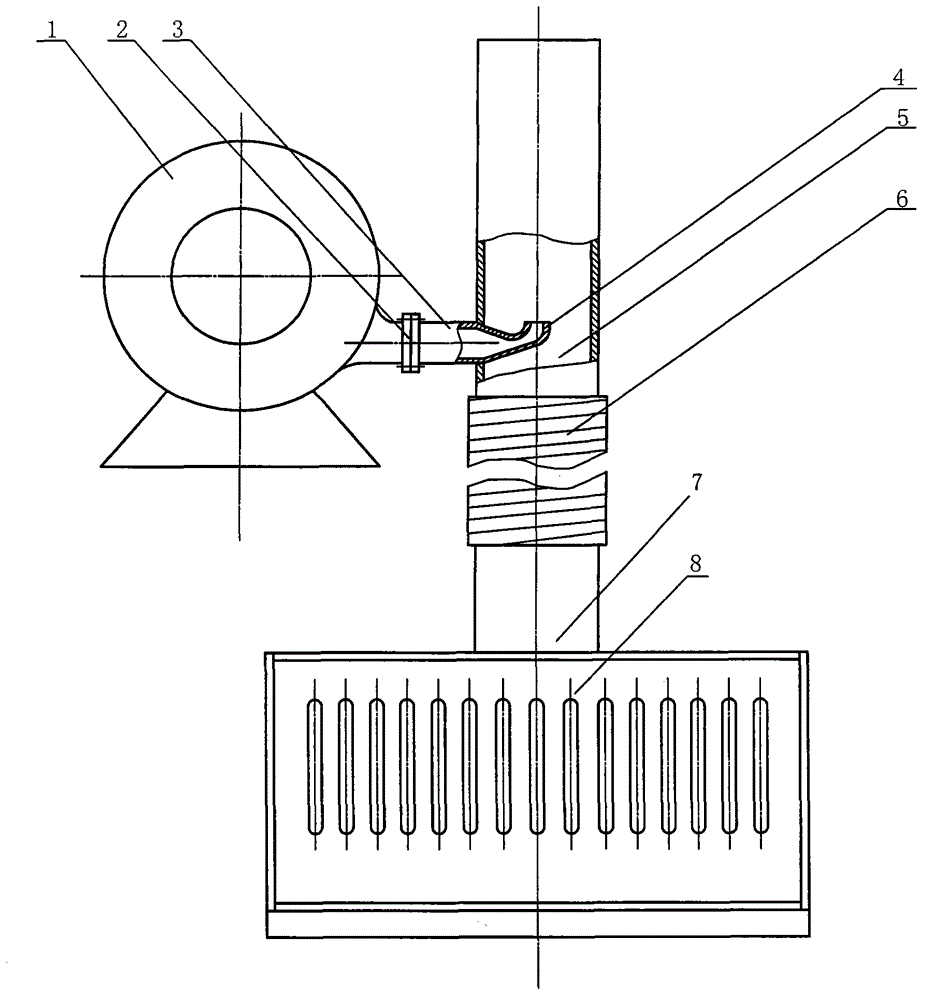

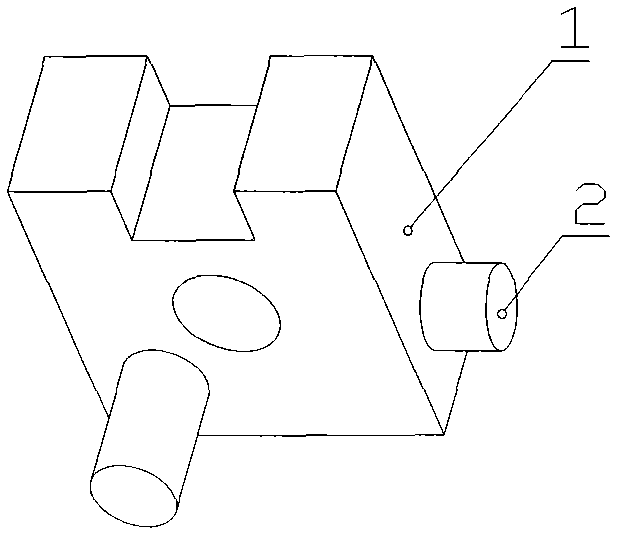

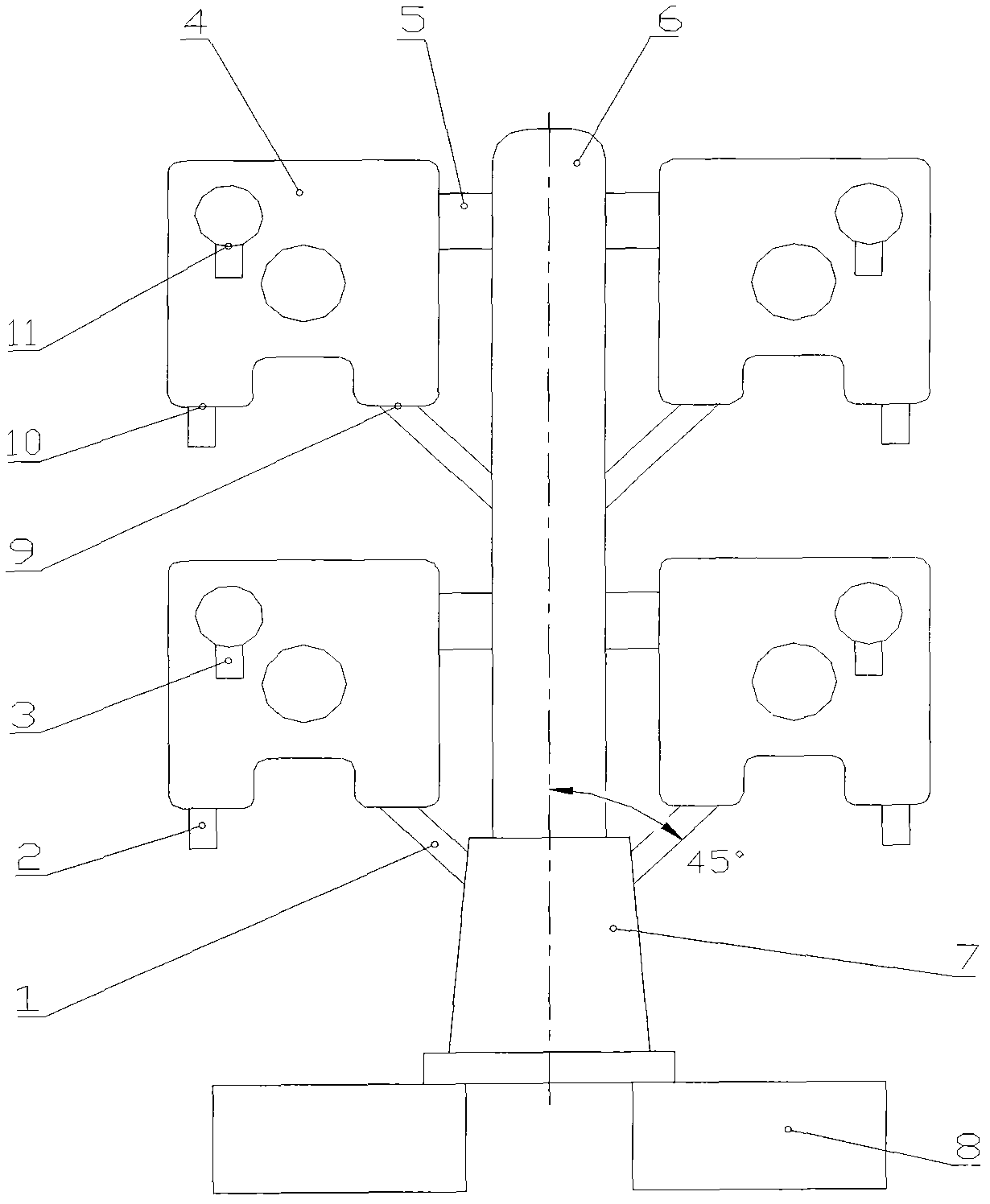

Range hood with external draught fan

InactiveCN104006429AEasy to useNo cleaning requiredDomestic stoves or rangesLighting and heating apparatusFlueSpray nozzle

The invention relates to a range hood with an external draught fan, and particularly relates to a range hood suitable for household use. The range hood comprises a draught fan (1), a flange (2), an air duct (3), a spray nozzle (4), a jet pipe (5), a soft pipe flue (6), a flue (7) and a hood (8). The draught fan (1) takes in fresh air; air flow blown by the draught fan (1) passes through the air duct (3), enters the spray nozzle (4) and is sprayed out at a high speed; a negative pressure is formed in the jet pipe (5); oil fume in a kitchen is sucked into the hood (8); the oil fume passes through the flue (7) and the soft pipe flue (6); and the oil fume is sucked in by the jet pipe (5) and is sprayed out together with the jet stream. The range hood with the external draught fan is advantageous in that the draught fan takes in the fresh air, blades of the draught fan can be kept clean, and the range hood is in no need of cleaning, and is convenint for use.

Owner:WEILE ENERGY TECH BEIJING CO LTD

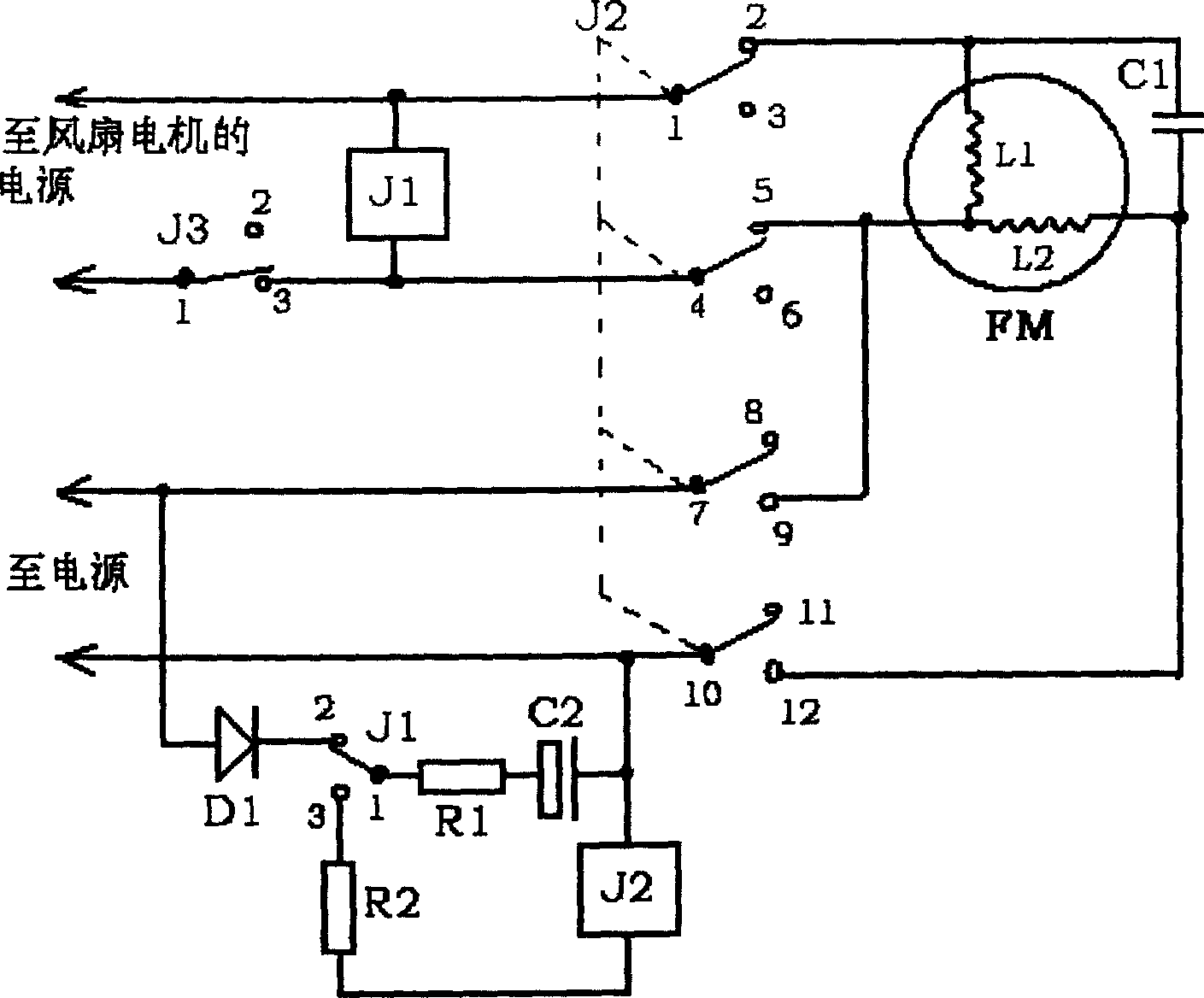

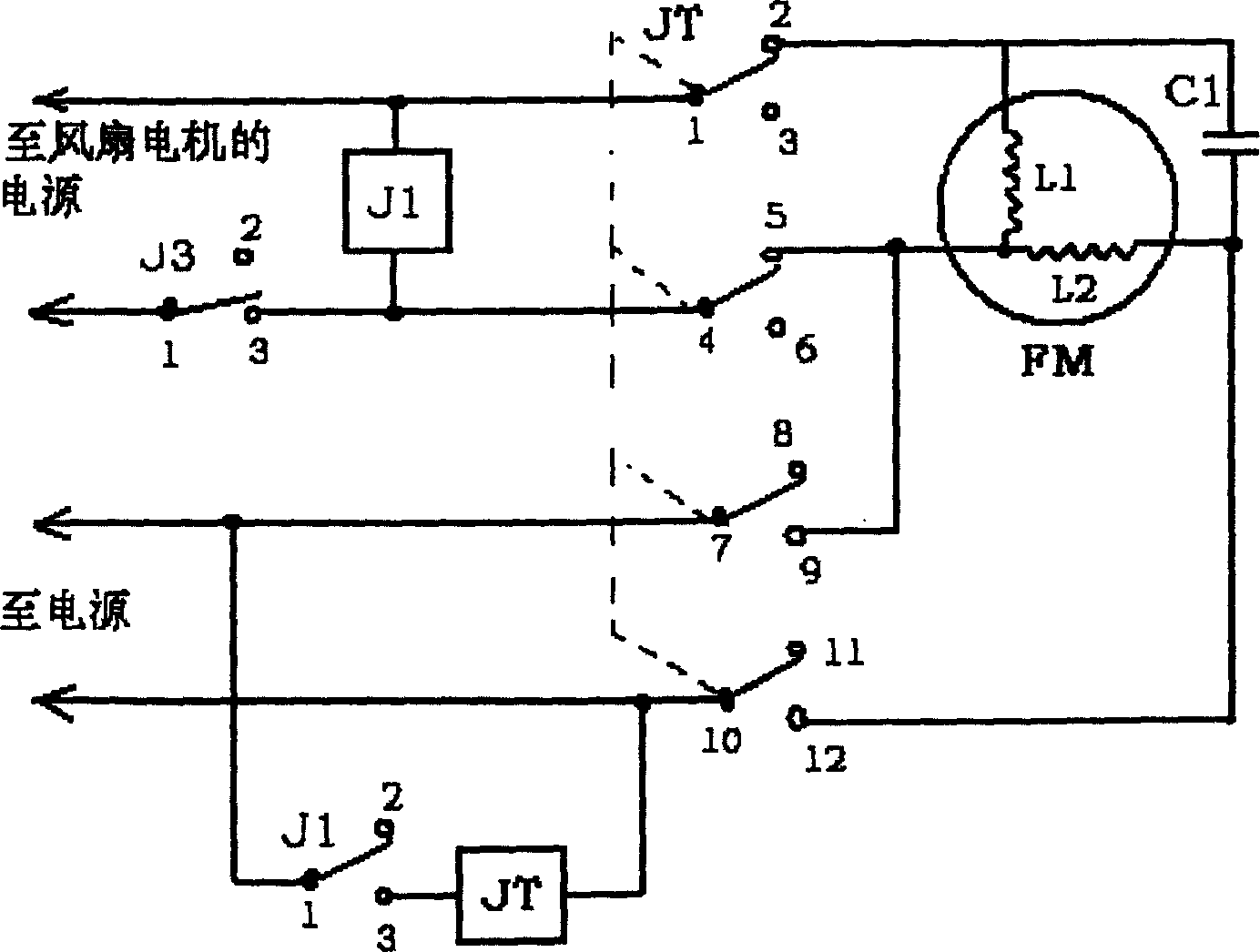

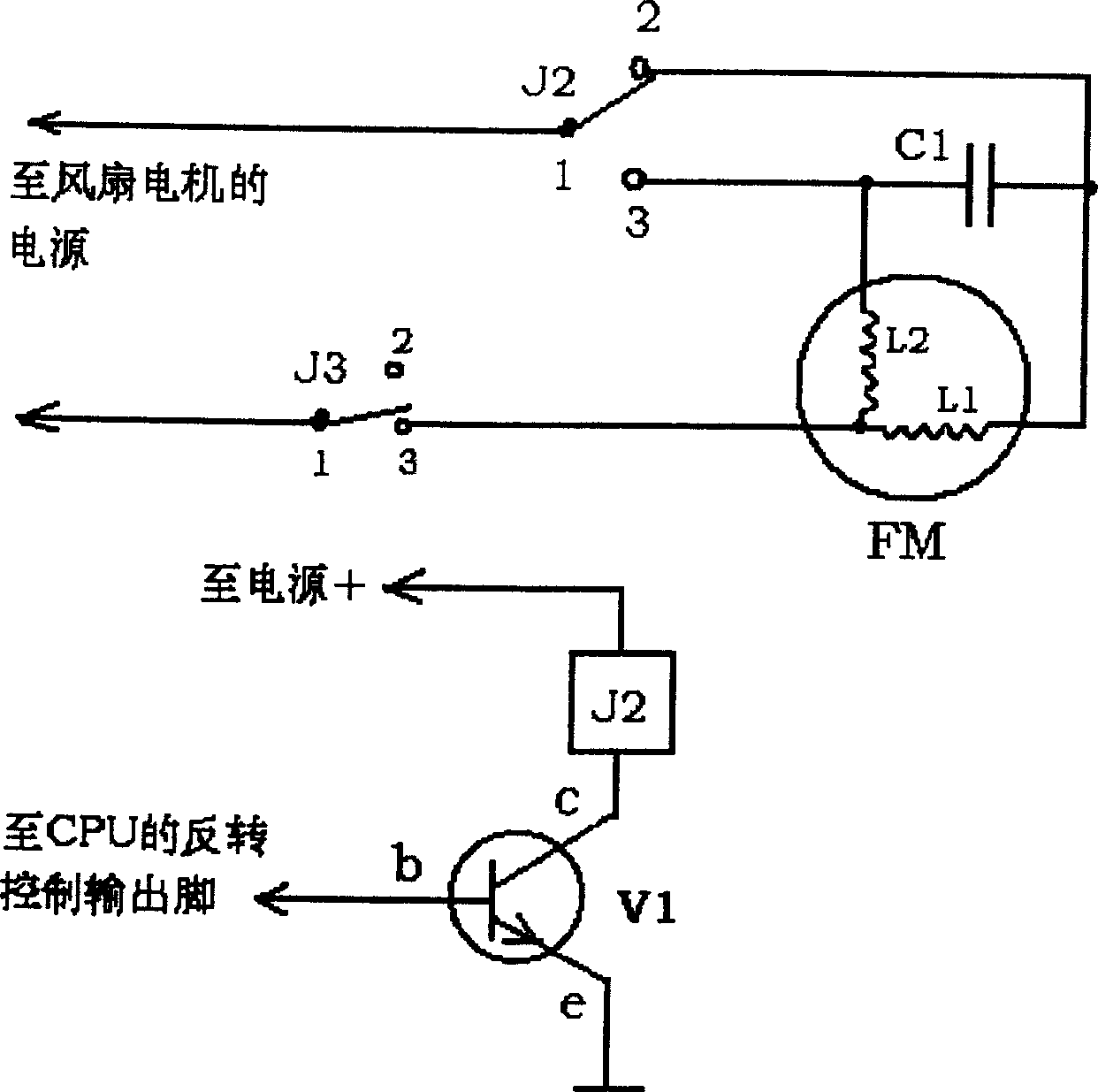

Air conditioner

InactiveCN1687658APrevent dirty cloggingNo cleaning requiredSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringElectrical and Electronics engineering

The invention is the air-conditioner to prevent the blocking and the dirt of the condenser. The invention sets the circuit that controls the rotary of the electric machine of the fan in the control circuit of the outdoor electric machine of the air-conditioner, and makes the fan of the outdoor machine reverses for a while after each stopping of revolving and uses the reversing wind to blow off the dust just absorbing on the condenser to prevent the blocking of the condenser.

Owner:代少春

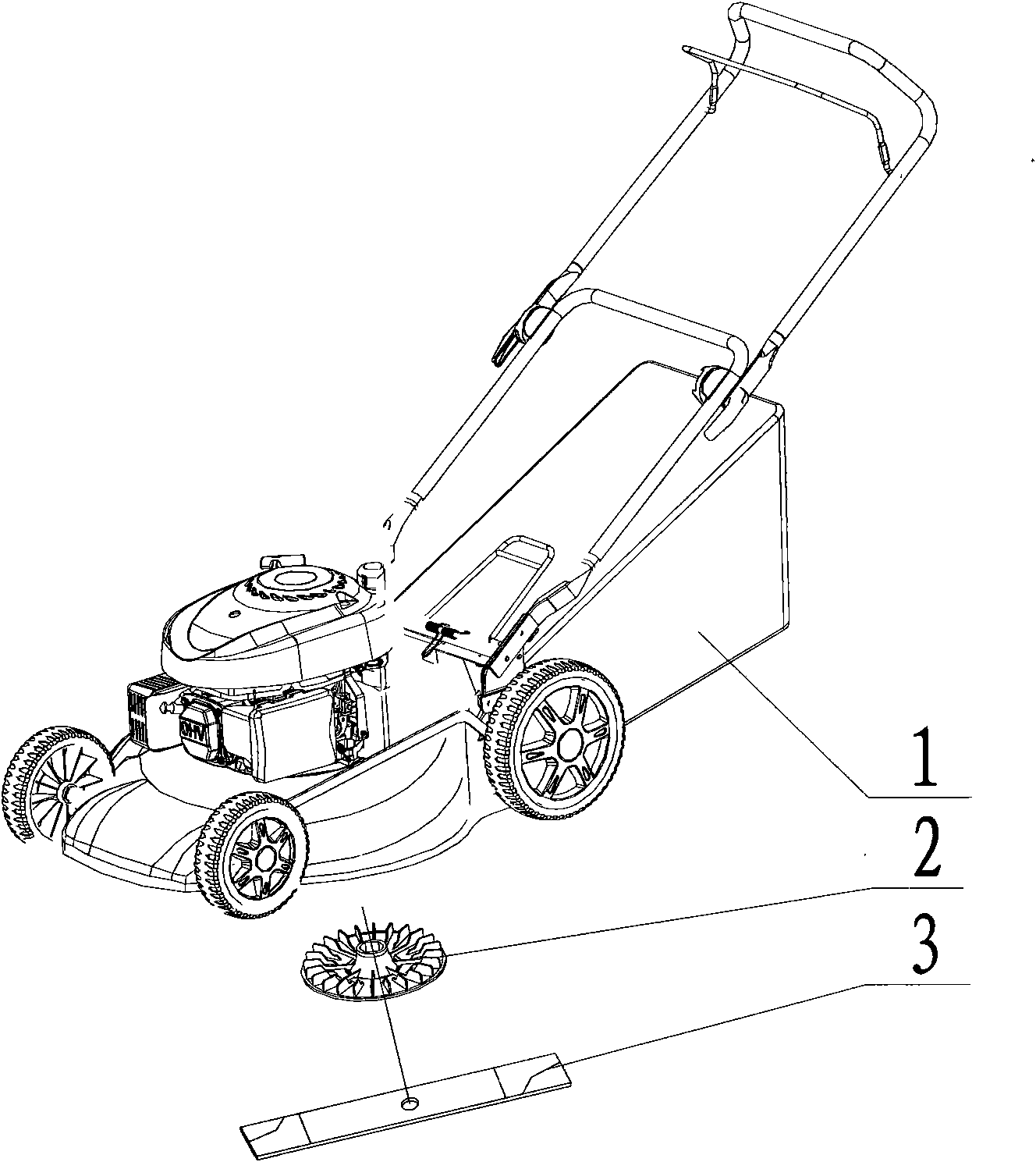

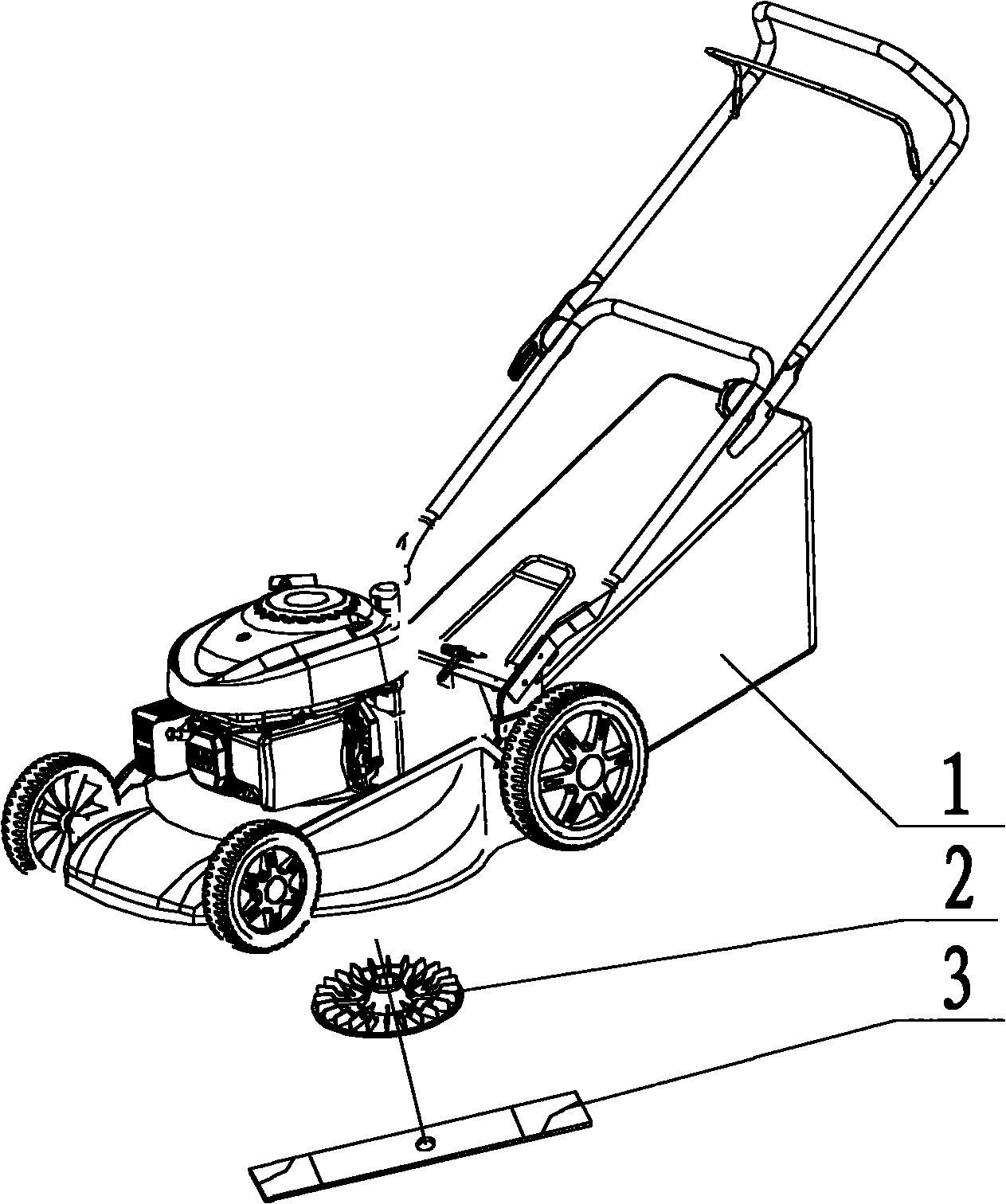

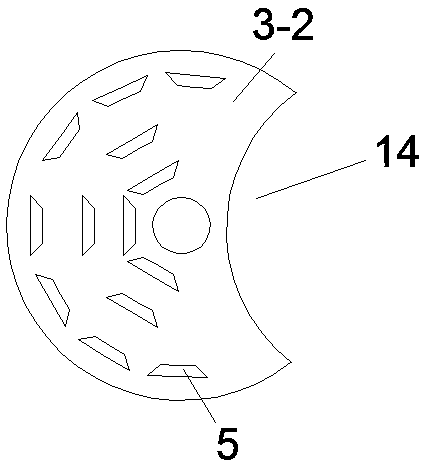

Straw-collecting device of mowing machine

The invention discloses a straw-collecting device of a mowing machine. The straw-collecting device comprises a power output shaft, a straw-collecting bag and a straw-collecting channel which are arranged on the mowing machine and a straw-collecting fan, wherein the straw-collecting fan is arranged on the power output shaft of the mowing machine. The invention has the advantage of high straw-collecting efficiency, and can lower the mowing cost and save the labor, thereby improving the mowing efficiency.

Owner:陈建刚

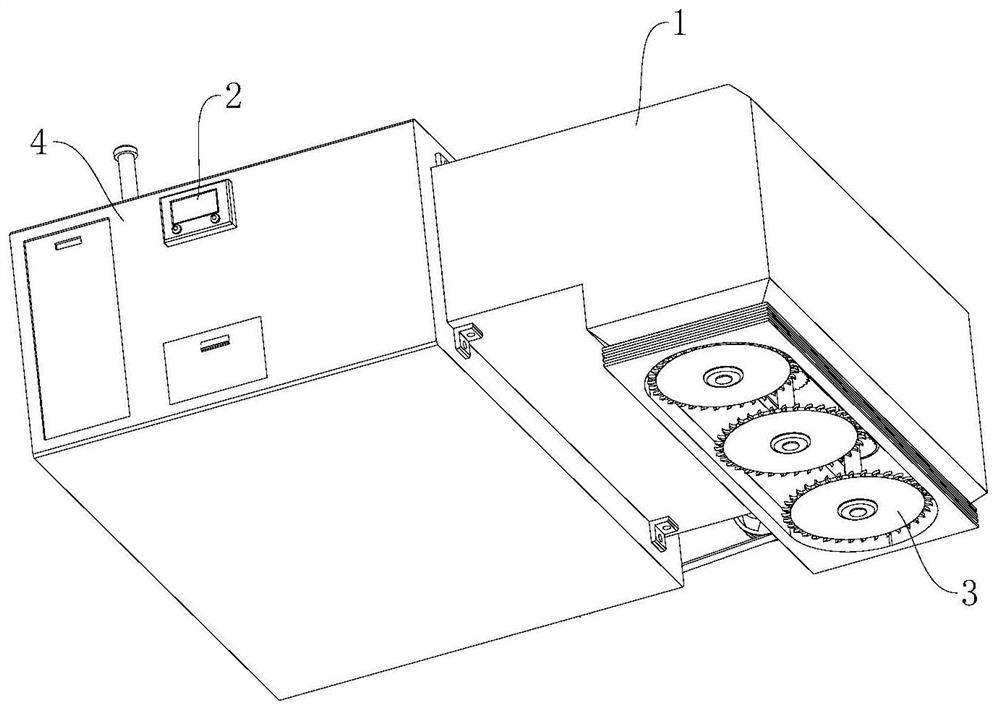

Hedge trimming equipment with cleaning function

ActiveCN111758414AGuaranteed uniformityImprove aestheticsHedge trimming apparatusPlant waste comminutingAgricultural scienceLeaf blade

The invention relates to the field of plant protection, in particular to hedge trimming equipment with a cleaning function. The equipment comprises an adsorption pipe and further comprises a controller, a trimming mechanism and a cleaning mechanism, the trimming mechanism is arranged in the adsorption pipe and is used for trimming hedgerow, the trimming mechanism comprises a driving assembly and three rotary blades, the cleaning mechanism comprises a cleaning box, an adsorption assembly and a cutting assembly, the cleaning box is fixedly arranged at one end of the adsorption pipe, the cleaningbox is communicated with the adsorption pipe, the adsorption assembly is arranged at the end, close to the interior of the cleaning box, of the adsorption pipe, the cutting assembly is arranged at the end, close to the interior of the adsorption pipe, of the cleaning box, and the driving assembly and the controller are electrically connected. According to the hedgerow trimming equipment with thecleaning function, sheared hedgerow branches can be synchronously cut and screened together with hedgerow leaves and respectively collected during trimming, sweeping of plant protection personnel is not needed, meanwhile, hedgerow growth is facilitated, environmental pollution is reduced, and secondary utilization of resources is achieved.

Owner:姜瑞玉

Investment casting mold cavity cleaning method based on selected area laser powder sintering rapid proto-typing technology application

InactiveCN103128229AControl flow exclusionControl aggregationFoundry moulding apparatusWaxInvestment casting

Disclosed is an investment casting mold cavity cleaning method based on selected area laser powder sintering rapid proto-typing technology application. According to the technical scheme, the top end of a wax mold and the secondary top end of the wax mold are connected with a residue discharging channel and a residue collecting device in a welded mode in a mold set assembling process. After a shell manufacturing process and a dewaxing process, flowing discharging of a wax mold in a liquid state and gathering of remained residues can be effectively controlled in a baking process, so that a clean mold cavity is obtained. After a series of well-known investment casting technology such as smelting, pouring, sand cleaning and piece dropping, an investment casting with a surface and an interior being good in quality is obtained.

Owner:DONGFENG PRECISION CASTING CO LTD

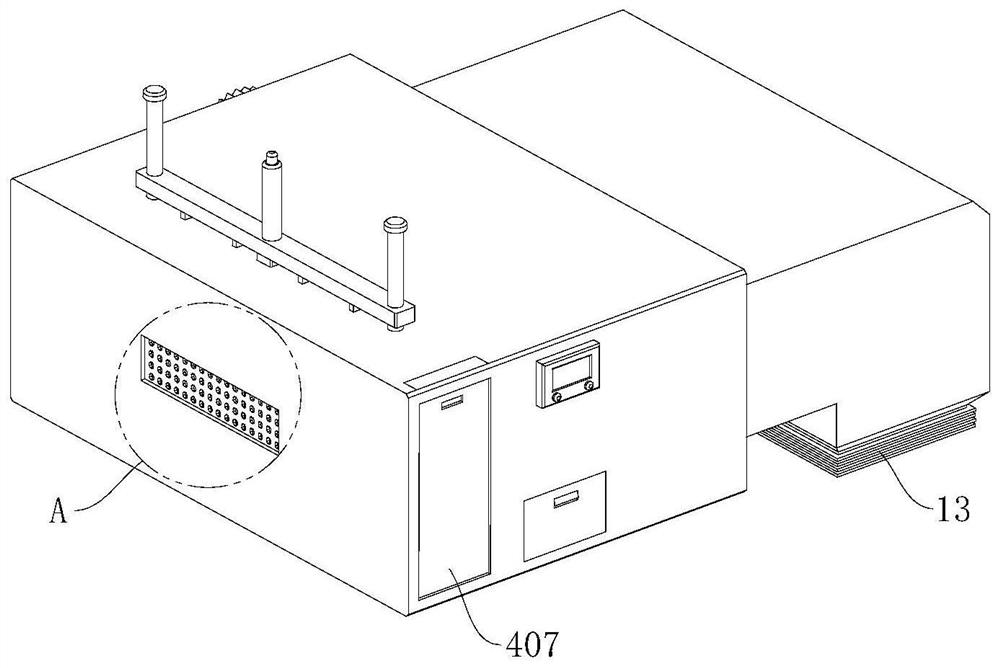

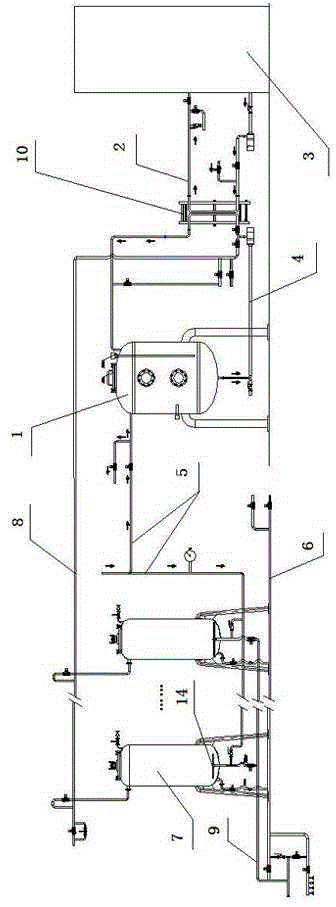

System and method for producing and culturing liquid spawns of edible fungus

The invention discloses a system and a method for producing and culturing liquid spawns of an edible fungus. The system comprises a nutrient solution sterilized tank, a heat exchanger, a cooling-water machine set and a plurality of liquid spawn culture tanks, and further comprises a nutrient solution circulation pipeline, a nutrient solution sterilization and cooling pipeline, a nutrient solution conveying pipeline, a germ-free compressed air inlet pipeline, a blow-off pipeline and a liquid spawn conveying pipeline. The invention further discloses a method for producing and culturing the liquid spawns of the edible fungus by using the system. According to the system and the method provided by the invention, residue spawns in the liquid spawn culture tanks can be used as stock cultures for again culture, so that the infection risks due to successive vaccination can be avoided; the sterilization, the cooling, the conveying and the germ-free air supply of the spawns are completed in inclosed vessels and pipelines, so that the infection probability is zero; the movement of the liquid spawn culture tanks is avoided, so that the investment is reduced, safety and reliability are realized, the amount of used labor is reduced, and the labor intensity is reduced.

Owner:LIANYUNGANG GUOXIN EDIBLE FUNGUS OF COMPLETE SETSOF EQUIP

Paste slurry drilling, grouting and impact extrusion expanded-head anchor rod structure system and construction method thereof

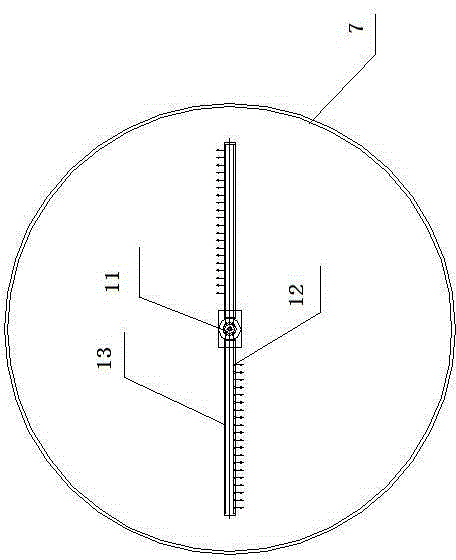

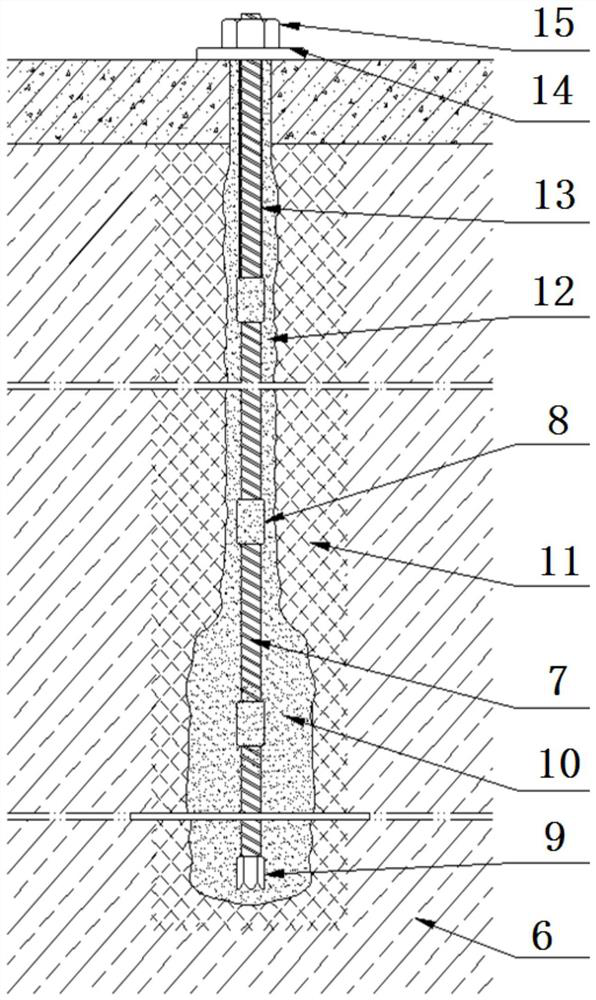

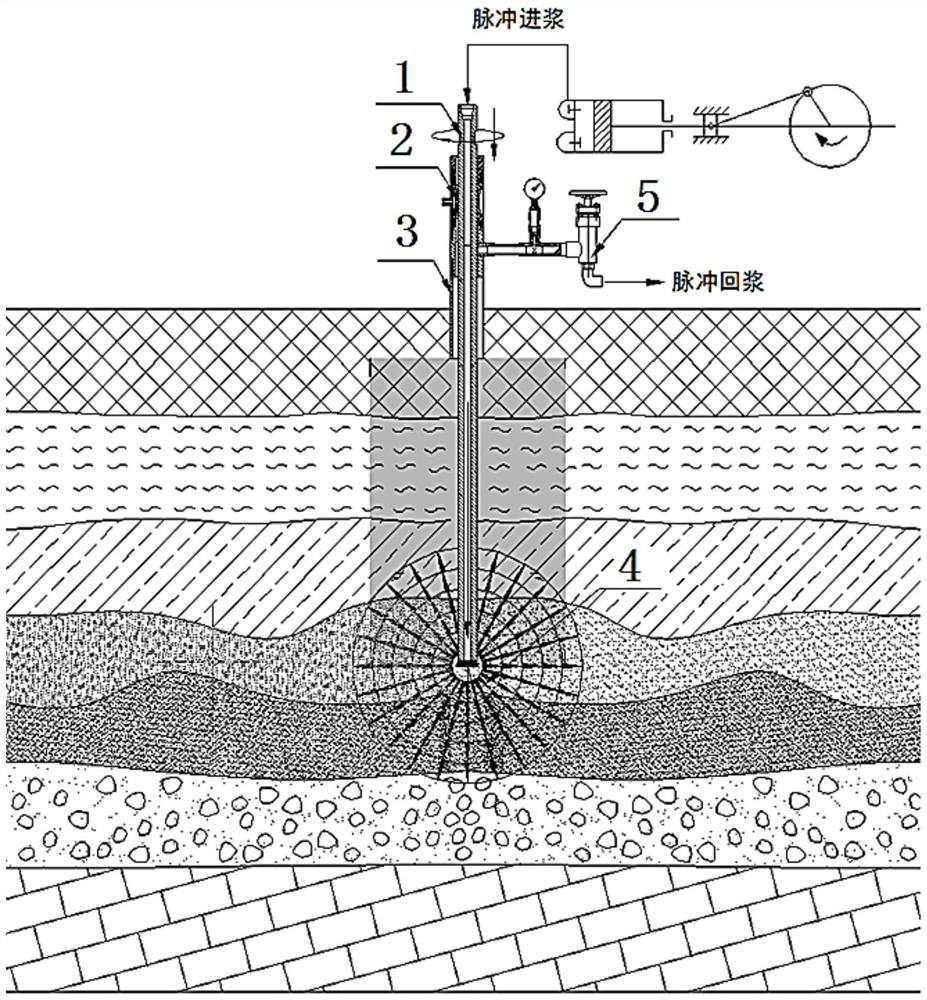

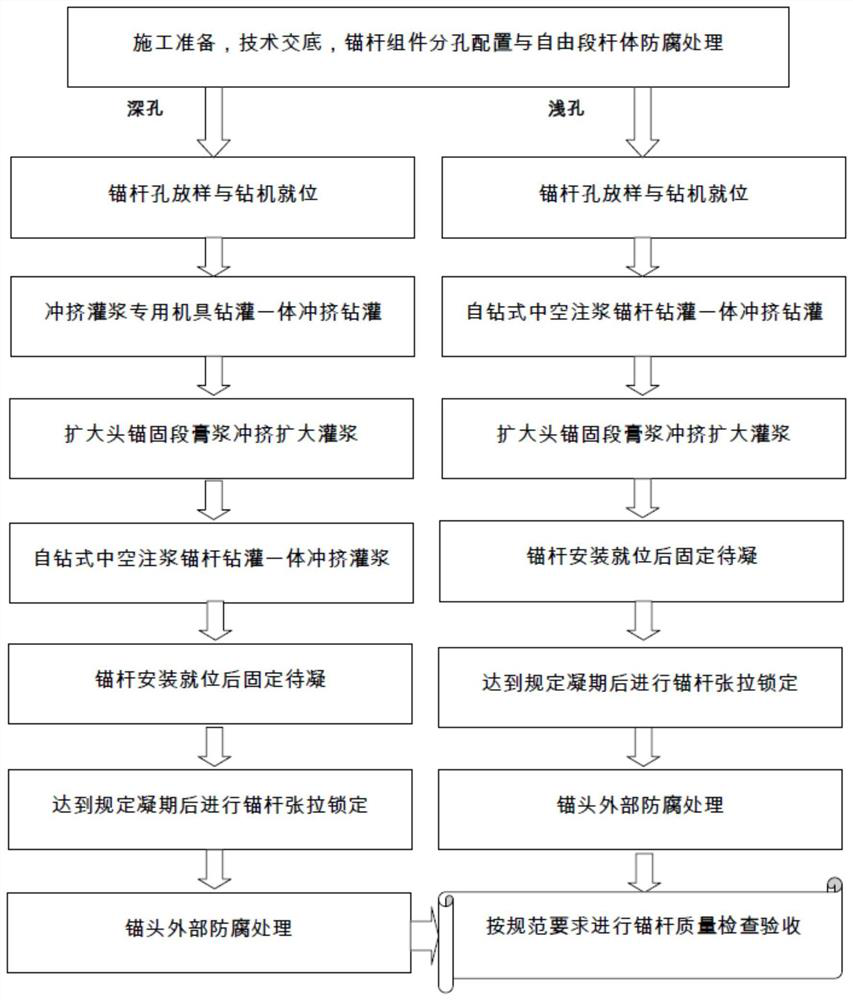

PendingCN111910615AImprove the pull-out capacitySmall amount of creepBulkheads/pilesSoil preservationSlurryRock bolt

The invention discloses a paste slurry drilling, grouting and impact extrusion expanded-head anchor rod structure system and a construction method thereof. According to the construction method, a self-drilling type hollow grouting anchor rod meeting the design requirement is directly used, and a drilling and grouting integrated in-situ impact extrusion grouting method is adopted, and middle-high pressure paste slurry impact extrusion drilling and grouting are conducted on full-hole section surrounding soil from top to bottom; and then a paste slurry pulse high-pressure pile squeezing and splitting method is adopted for conducting segmented reciprocating high-pressure paste slurry impact extrusion expanding grouting on an expanded-head anchoring hole section from bottom to top, after the expanded-head anchoring section meeting the design requirement is formed, middle-high pressure paste slurry impact extrusion drilling and grouting are conducted from top to bottom, and the self-drillingtype hollow grouting anchor rod is installed in place, so that the composite anchor rod structure system is formed, wherein the composite anchor rod structure system is combined with the self-drilling type hollow grouting anchor rod, and the composite anchor rod structure system is composed of upper non-anchored section middle-high pressure paste slurry impact extrusion grouting composite surrounding soil, a lower anchored section high-pressure paste slurry impact-extrusion expanded head pile body, a pile periphery slurry extrusion and splitting vein and a compacted soil body. The paste slurry drilling, grouting and impact extrusion expanded-head anchor rod structure system is convenient to construct, small in waste slurry amount, safe, environment-friendly and controllable in quality.

Owner:POWERCHINA ZHONGNAN ENG +1

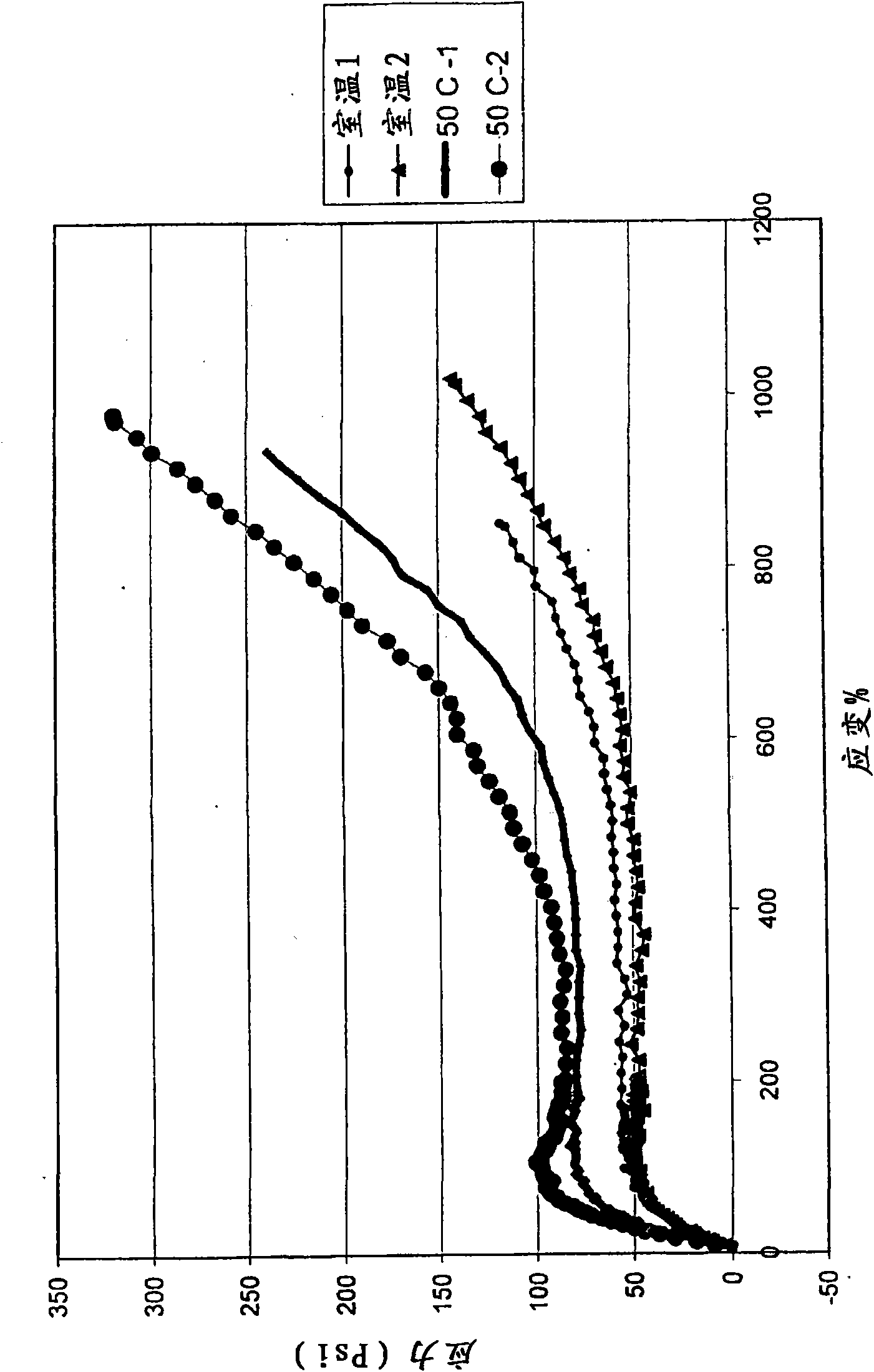

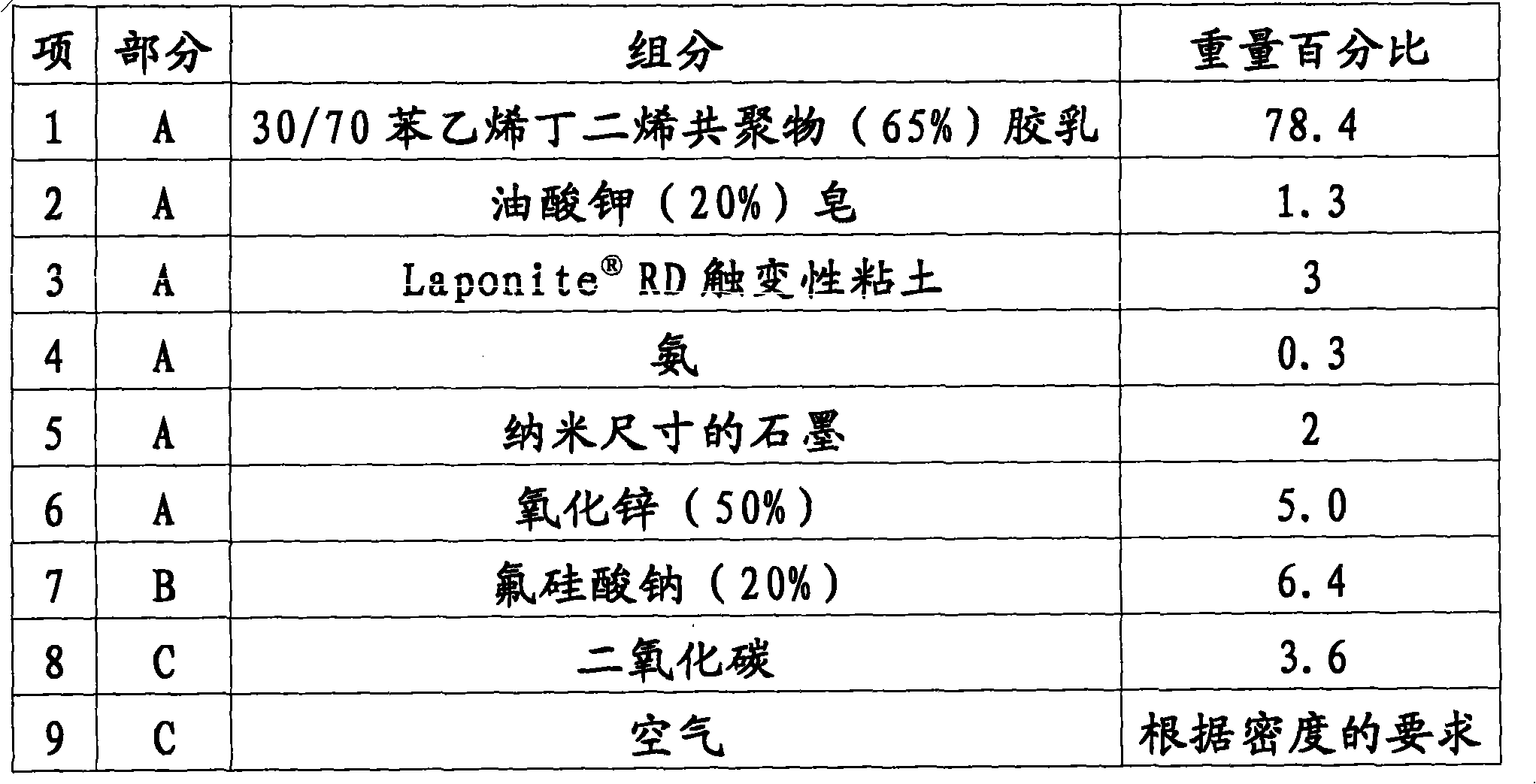

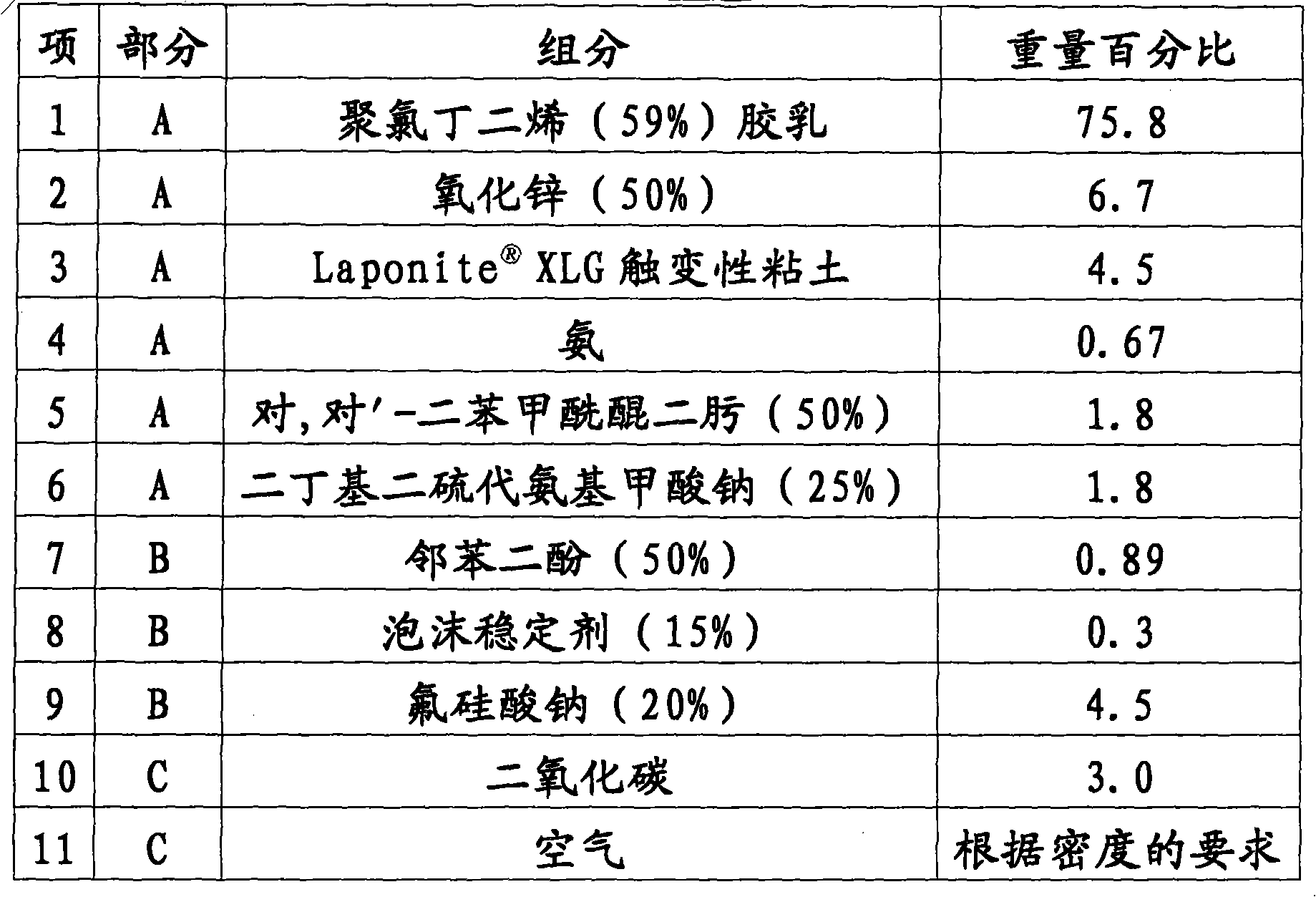

Spray-in latex foam for sealing and insulating

A spray latex foam for filling wall cavities to enhance the sealing and insulating properties of a building is provided. The spray latex foam includes a latex system and a gaseous coagulating component. In at least one exemplary embodiment, carbon dioxide is included as a gaseous coagulating agent. One latex suitable for use in the spray foam is polyvinylidene chloride (PVDC), which possesses fireretardancy and environmental durability. However, a preferred latex is styrene-butadiene rubber (SBR). The latex system may also include a thixotropic agent, such as Laponite<*>RD synthetic clay. Thespray latex foam is polyurethane-free. A method of preparing a spray latex foam that includes supplying a latex system and adding a gaseous coagulating component to the latex system is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Coloring pigment bottle structure

A coloring pigment bottle structure comprises a bottle body, a cover body and a stirring structure. The stirring structure comprises a stirring rod penetrating through the cover body and extending into the bottom of the bottle body. The lower end of the stirring rod is provided with a stirring disk. The stirring disk is provided with a through hole. The upper end and the lower end of the through hole are provided with scraper blades. The pigment at the bottom of the bottle body is directly stirred and evenly mixed through the stirring structure.

Owner:王铮澔

High-efficiency, energy-conservation and clean method for producing chromate

ActiveCN101508466BSolve pollutionAchieving the purpose of cleaner productionChromates/bichromatesDissolutionCleaning methods

The invention provides a method for producing chromate with high efficiency, energy conservation and cleanness. The method uses chromium iron as a raw material, and carries out oxidation dissolution in high-temperature high-pressure aqueous alkali to separate solid and liquid after temperature and pressure reduction so as to obtain a chromate solution, water and ferric oxide or mixture of the water, ferric oxide and chrome oxide. A high-temperature high-pressure reactor is used as the reactor of the method so as to greatly improve equipment efficiency and production efficiency. The method realizes autothermal reaction by system reaction heat to achieve the aim of energy conservation, and is an energy-saving process of chromate production. The method does not need external fuel to supply heating and does not generate waste gas, and the reaction precipitate is the water and the ferric oxide or the mixture of the water, the ferric oxide and the chrome oxide, wherein the water and the ferric oxide or the mixture of the water, the ferric oxide and the chrome oxide can be used for preparing chromium iron paint without generating waste residue; and washing of the precipitate adopts countercurrent washing, and washing water is used for preparing a reaction initial solution without generating waste water. The method does not generate the three wastes, and is a clean process for producing the chromate.

Owner:青海省博鸿化工科技股份有限公司

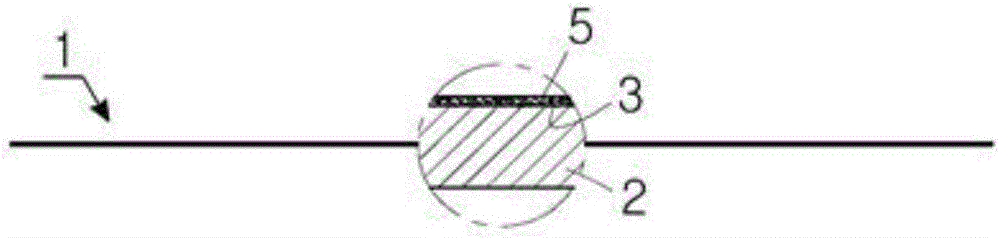

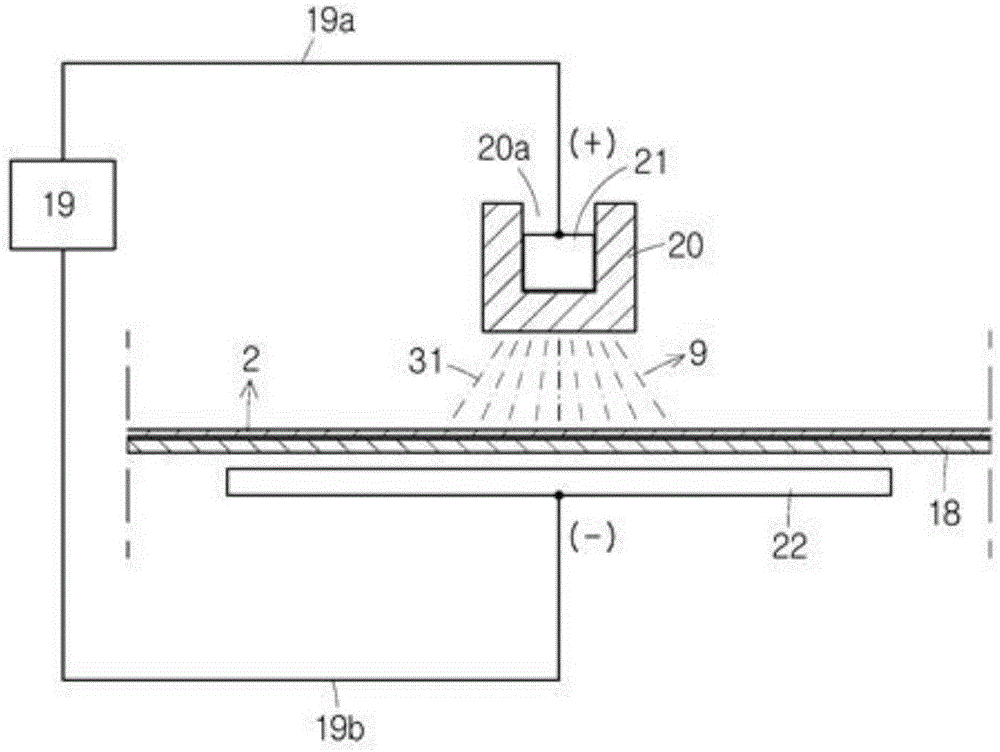

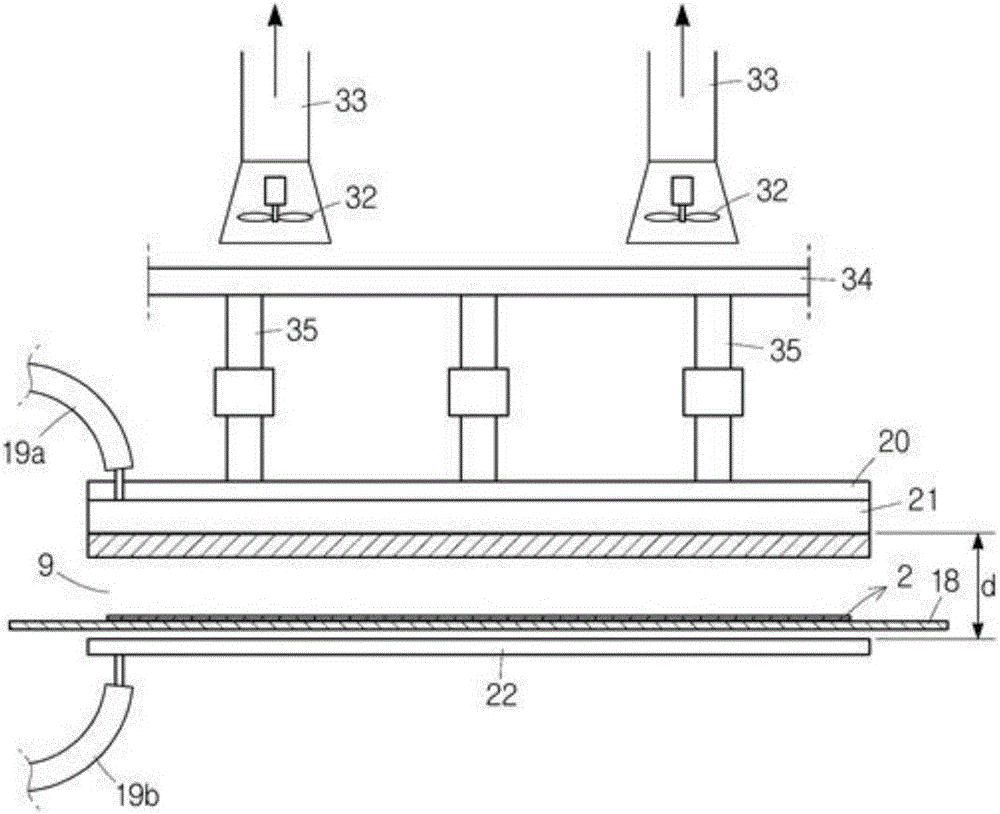

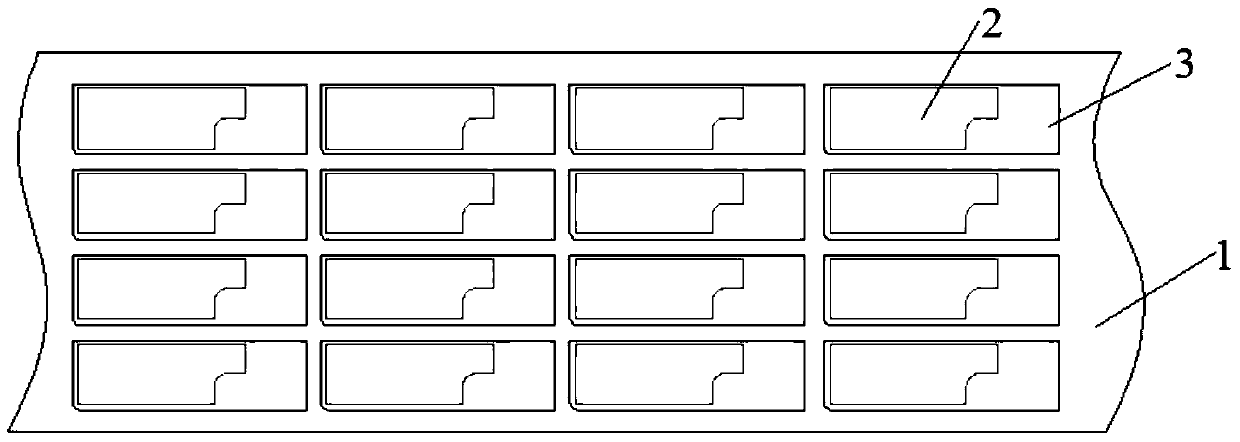

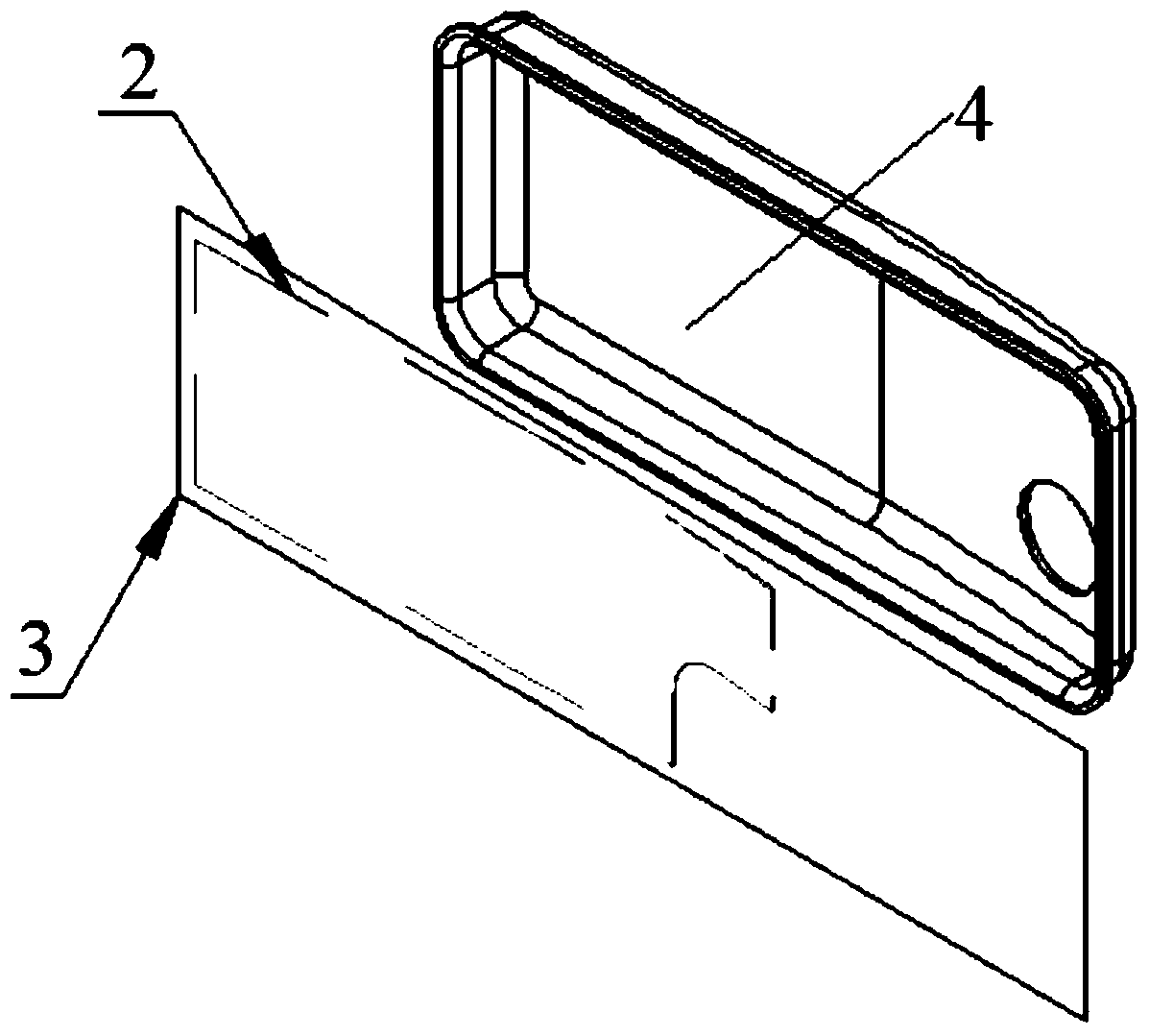

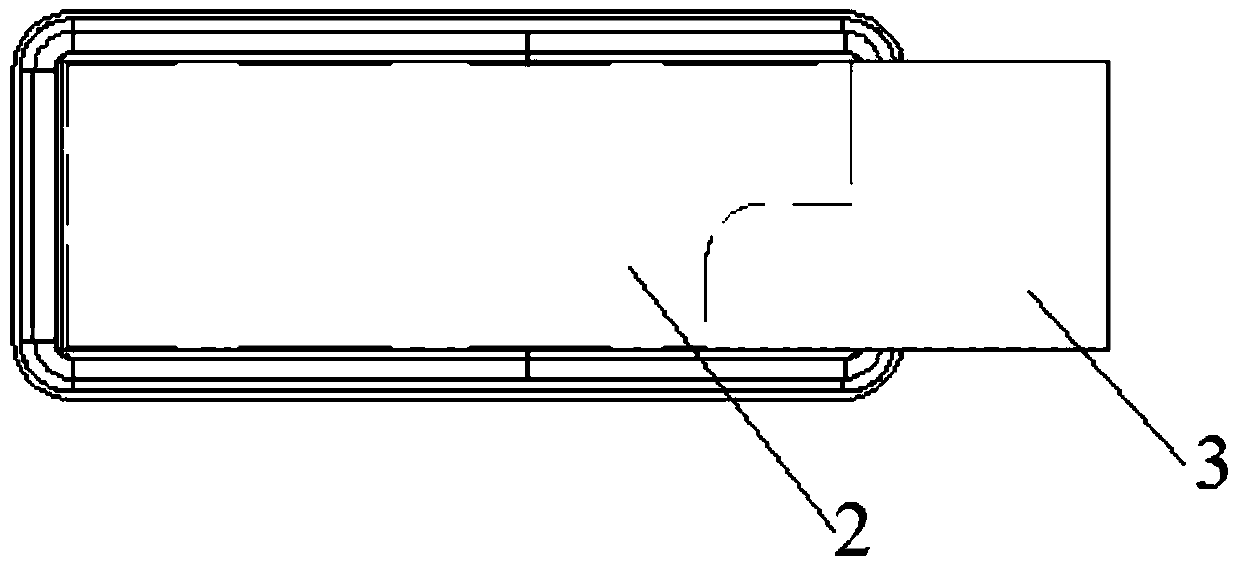

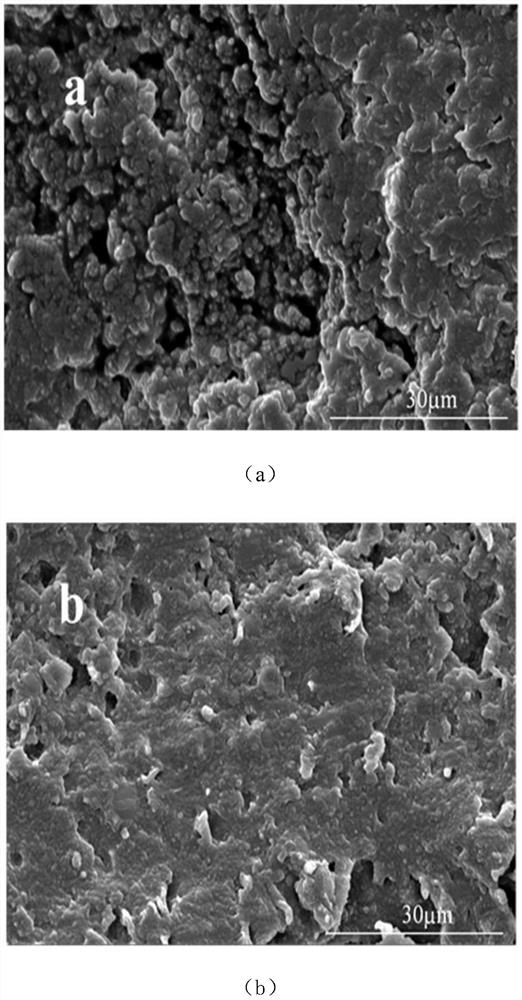

Surface treatment method for disposable grill using atmospheric plasma, surface treatment apparatus therefor, and disposable grill manufactured thereby

InactiveCN106105402AEffective and easy to applyEasy post-processingLiquid surface applicatorsRoasters/grillsFlavorFar infrared

The present invention provides a disposable grill which is formed by treating the surface of a base (2) consisting of aluminum sheet, aluminum foil, or the like with atmospheric plasma to form an ultrafine irregularity of about 10 and then coating the surface with a loess ceramic layer (5) having a predetermined thickness. The disposable grill can be disposed after use and is thus hygienic, does not require washing and the like and is thus easy to use, has a low production cost, and prevents meat from getting scorched and sticking to the grill or getting burned and prevents meat juice from drying up, due to the effect of a large amount of far-infrared rays generated therein, so that a user can enjoy soft and unique flavors of meat (savory taste and odor, etc.).

Owner:朴畅济 +1

High-strength fiberglass pipe and production method thereof

The invention discloses a high-strength glass fiber reinforced plastic pipeline and a production method thereof, and belongs to the technical field of glass fiber reinforced plastic pipelines and production methods thereof. The high-strength glass fiber reinforced plastic pipeline is a circular pipeline, and is characterized by comprising a lining layer, an inner structural layer, a middle sand inclusion layer and an outer structural layer, wherein the lining layer is formed by soaking and bonding a glass fiber surface felt layer, a glass fiber knitted felt layer and a grid cloth layer in sequence through lining resin from inside to outside; the inner structural layer and the outer structural layer are constructed by one or more glass fiber yarn annular winding layers and one or more glass fiber yarn crossed winding layers; the annular winding layers and the crossed winding layers are formed at intervals; the middle sand inclusion layer consists of upper layer sand inclusion cloth, lower layer sand inclusion cloth and a sand material compressed and clamped between the upper layer sand inclusion cloth and the lower layer sand inclusion cloth; the sand material is formed by mixing quartz sand and sand adhesion resin. The pipeline has the advantages of high compressive strength, high axial tensile strength, large pipe diameter span, light weight, high hydraulic performance, freeness from scaling, insulation, flame retardance and corrosion resistance.

Owner:HUNAN XIAOXIANGYUAN TECH DEV

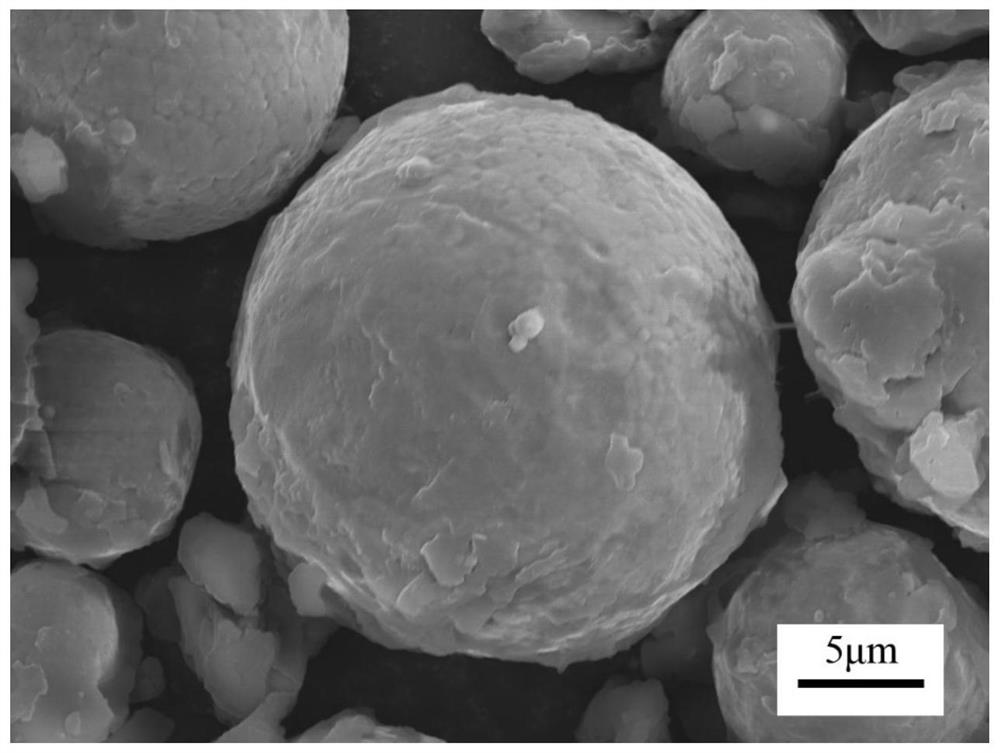

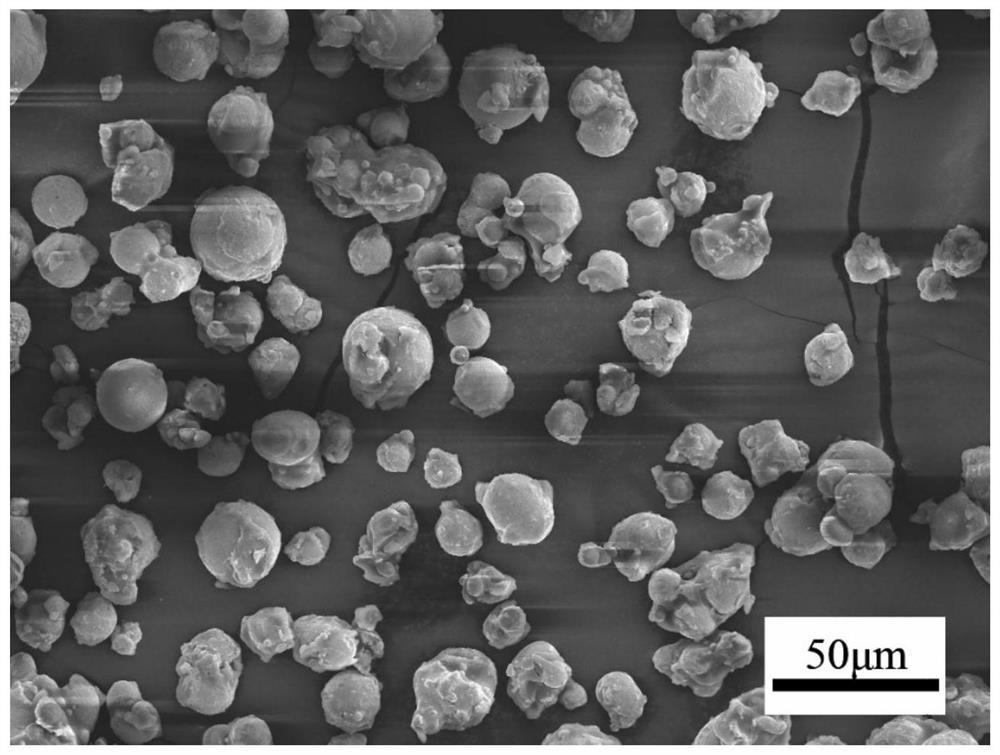

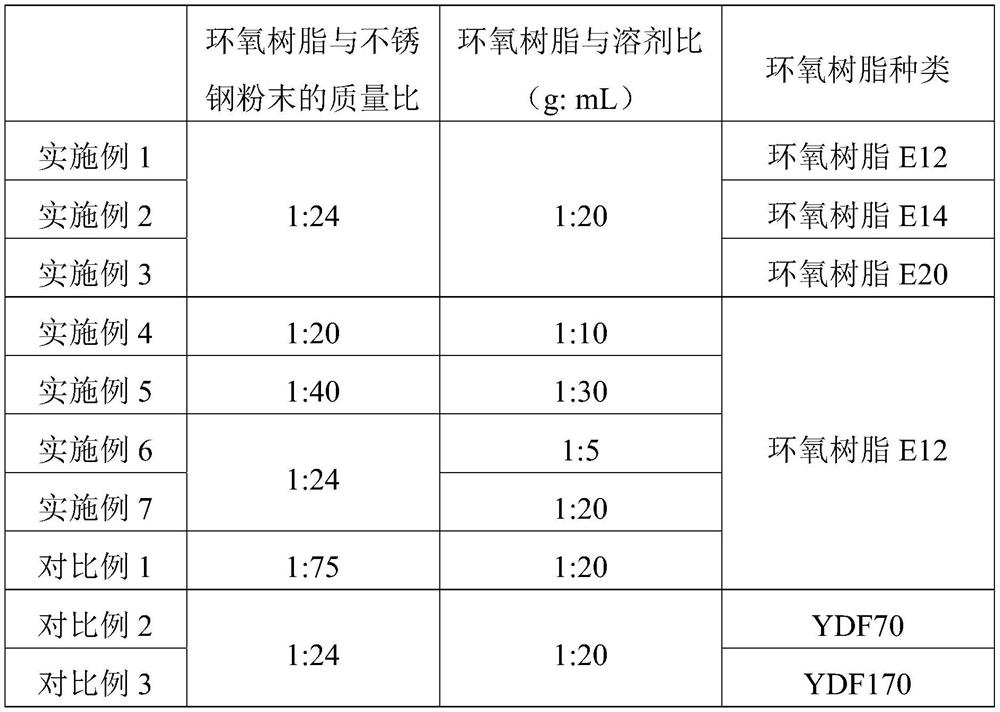

Preparation method and application of epoxy resin coated stainless steel powder

PendingCN112792333AImprove liquidityReduce dosageAdditive manufacturing apparatusTransportation and packagingSolventBisphenol A

The invention relates to a preparation method of epoxy resin coated stainless steel powder. The preparation method comprises the following steps of dissolving epoxy resin in a solvent, adding stainless steel powder, stirring until the solvent is volatilized, and sequentially conducting drying, grinding and screening, wherein the mass ratio of the epoxy resin to the stainless steel powder is 1: (20-50), and the epoxy resin is solid bisphenol A epoxy resin. According to the preparation method, the epoxy resin is dissolved in the solvent, the resin is separated out and coated on the surface of the stainless steel through solvent volatilization, in the process, the fluidity and dispersity of the stainless steel powder are good, the coating effect is improved, the prepared coated powder is good in sphericity degree and less in powder agglomeration, and the phenomena of agglomeration, uneven coating and the like of the coated powder are effectively reduced. No antioxidant or dispersing agent is added, introduction of impurities is reduced, the preparation process is simple, subsequent further impurity removal is not needed, and the requirement for equipment is low.

Owner:北京科技大学广州新材料研究院

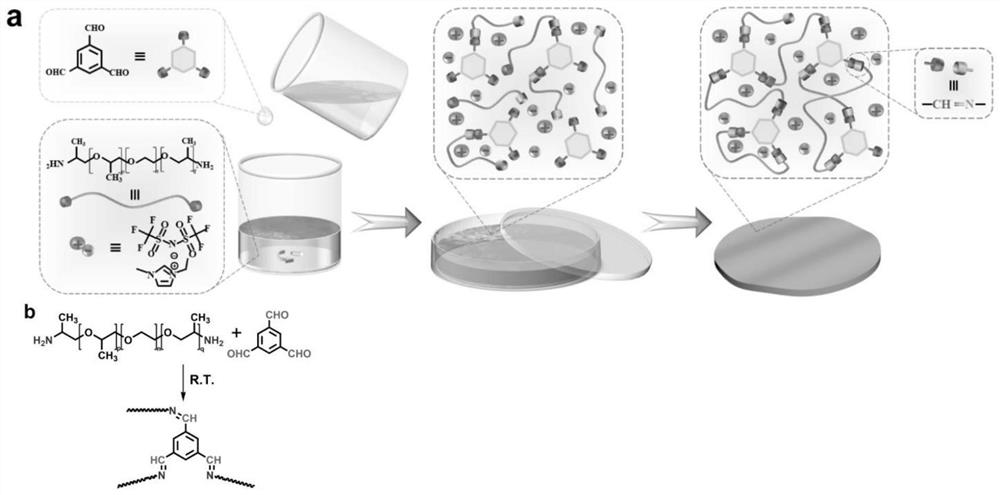

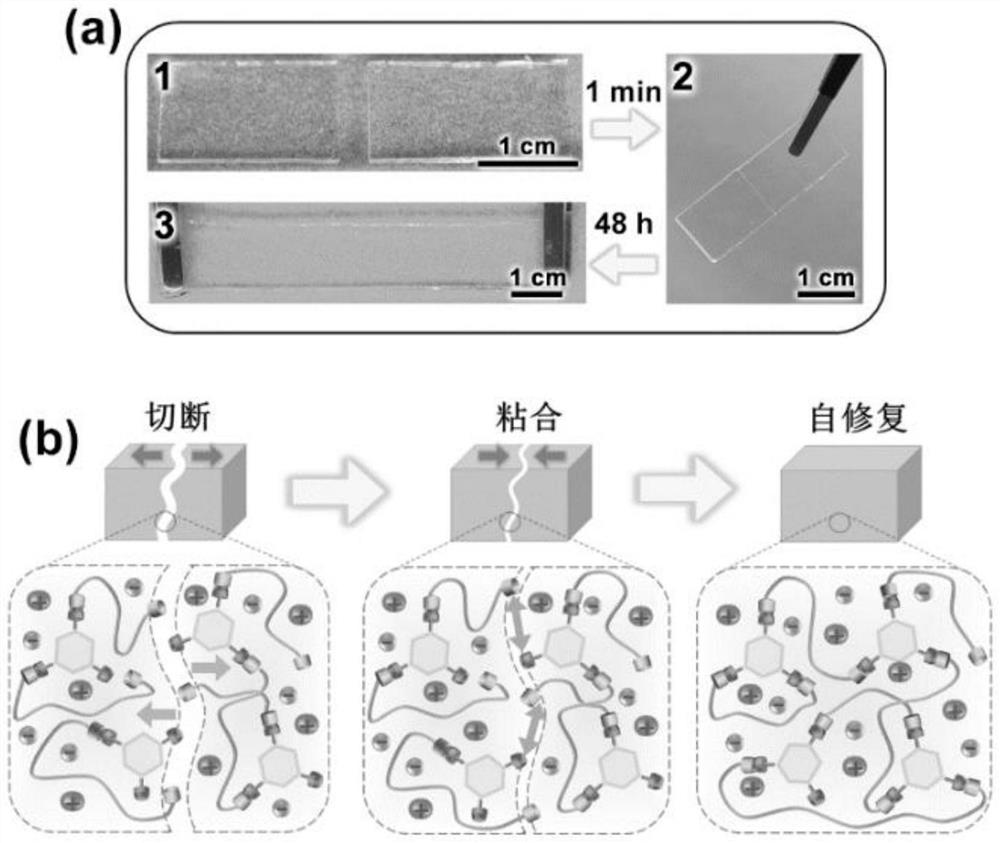

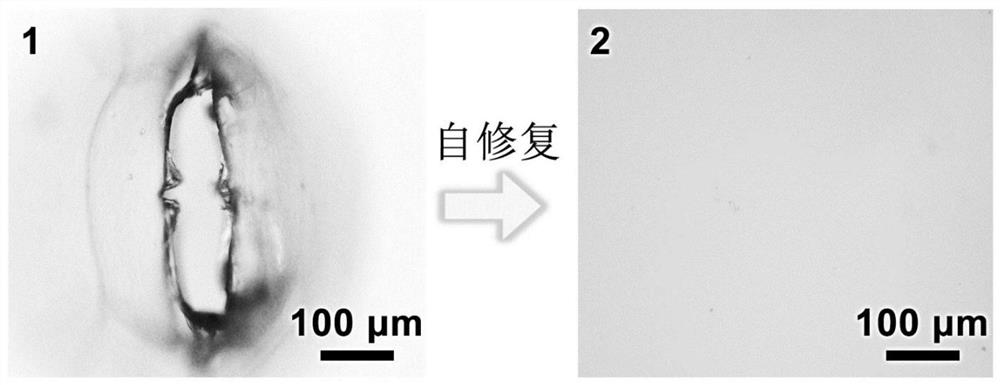

Room-temperature self-repairing ionic gel as well as preparation method and application thereof

PendingCN114195968AStable structureImprove stabilitySemi-permeable membranesDispersed particle separationPolymer scienceOligomer

The invention provides room-temperature self-repairing ionic gel as well as a preparation method and application thereof, and belongs to the technical field of gas separation. A double-amino-terminated oligomer and a trialdehyde crosslinking agent are used as raw materials, based on a Schiff reaction of amino and aldehyde, the double-amino-terminated oligomer and the trialdehyde crosslinking agent can form a supramolecular polymer network (I-SPNs) crosslinked by dynamic imine bonds, and the crosslinked polymer network wraps an ionic liquid, so that the ionic liquid is dispersed in the supramolecular polymer network, and the ionic liquid is dispersed in the supramolecular polymer network. The cross-linked polymer network structure has high cross-linking density, so that the mechanical strength of the ionic gel is remarkably improved. The high bond energy of the dynamic imine bond and the polymer cross-linked network structure in the room-temperature self-repairing ionic gel endow the ionic gel with good stability, mechanical properties and repairing performance, so that the ionic gel can still keep efficient and stable gas permeability and separation performance after multiple times of physical shear mark damage.

Owner:JILIN UNIV

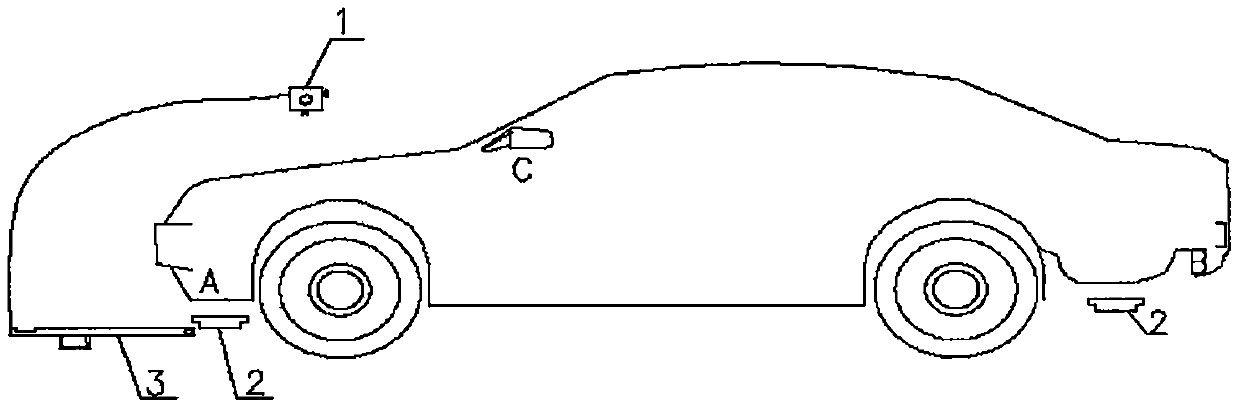

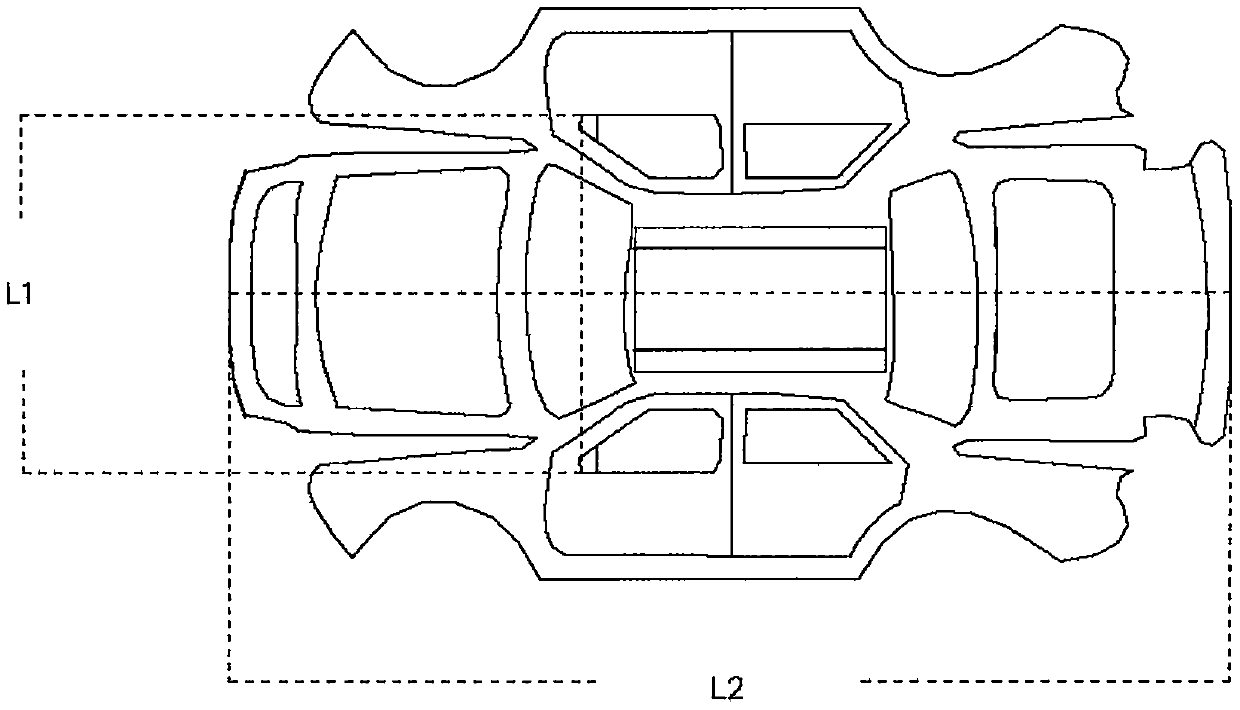

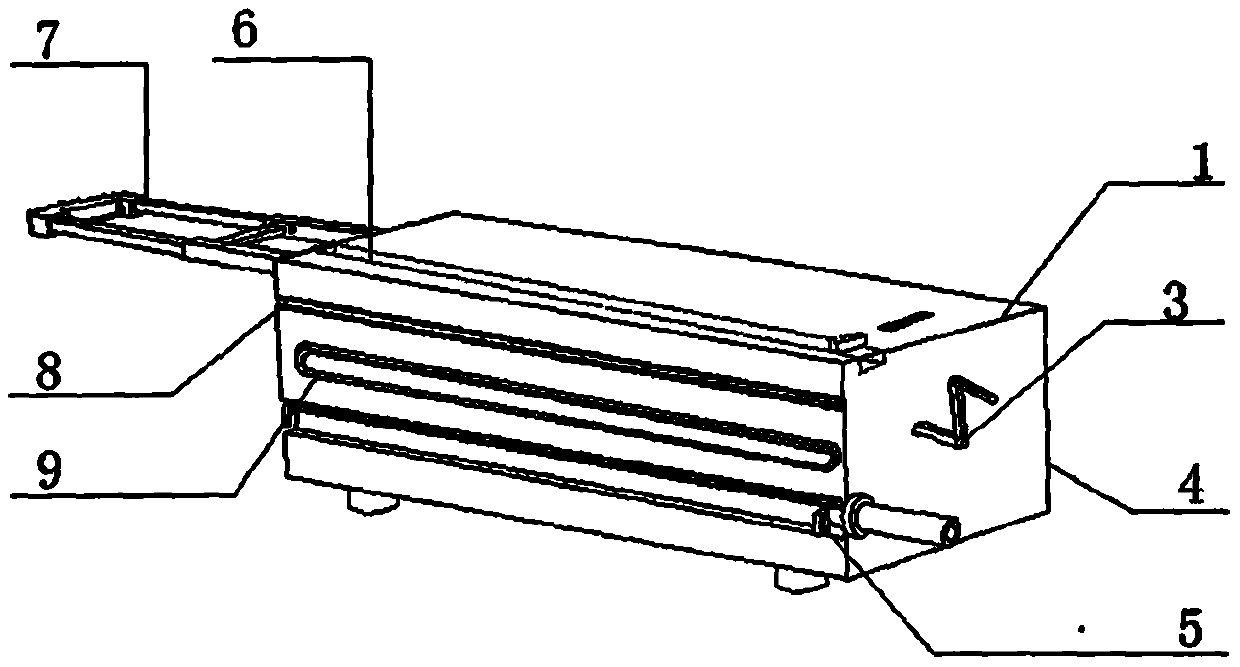

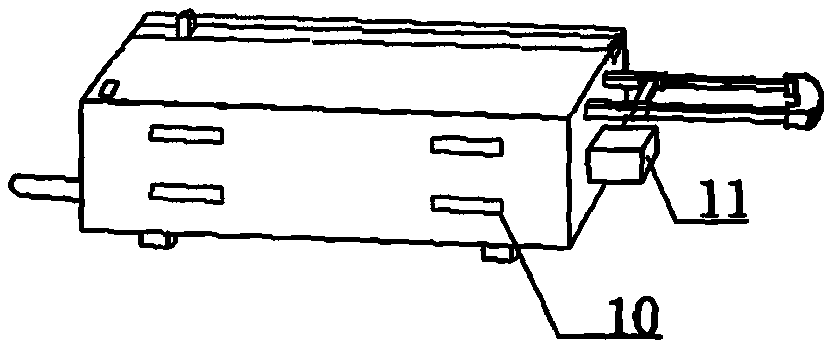

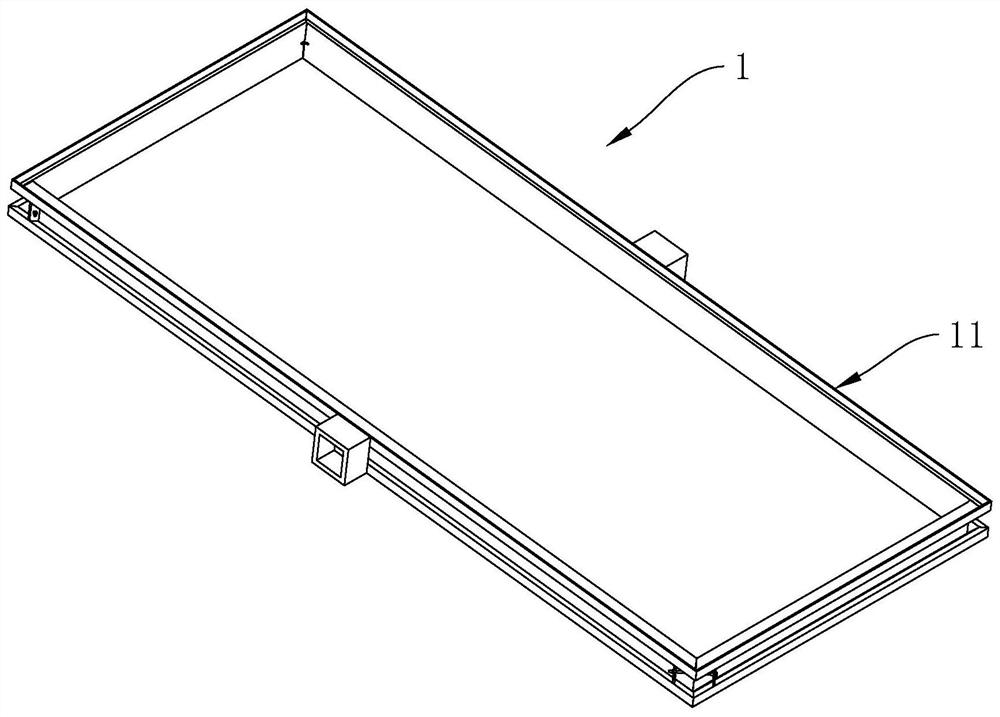

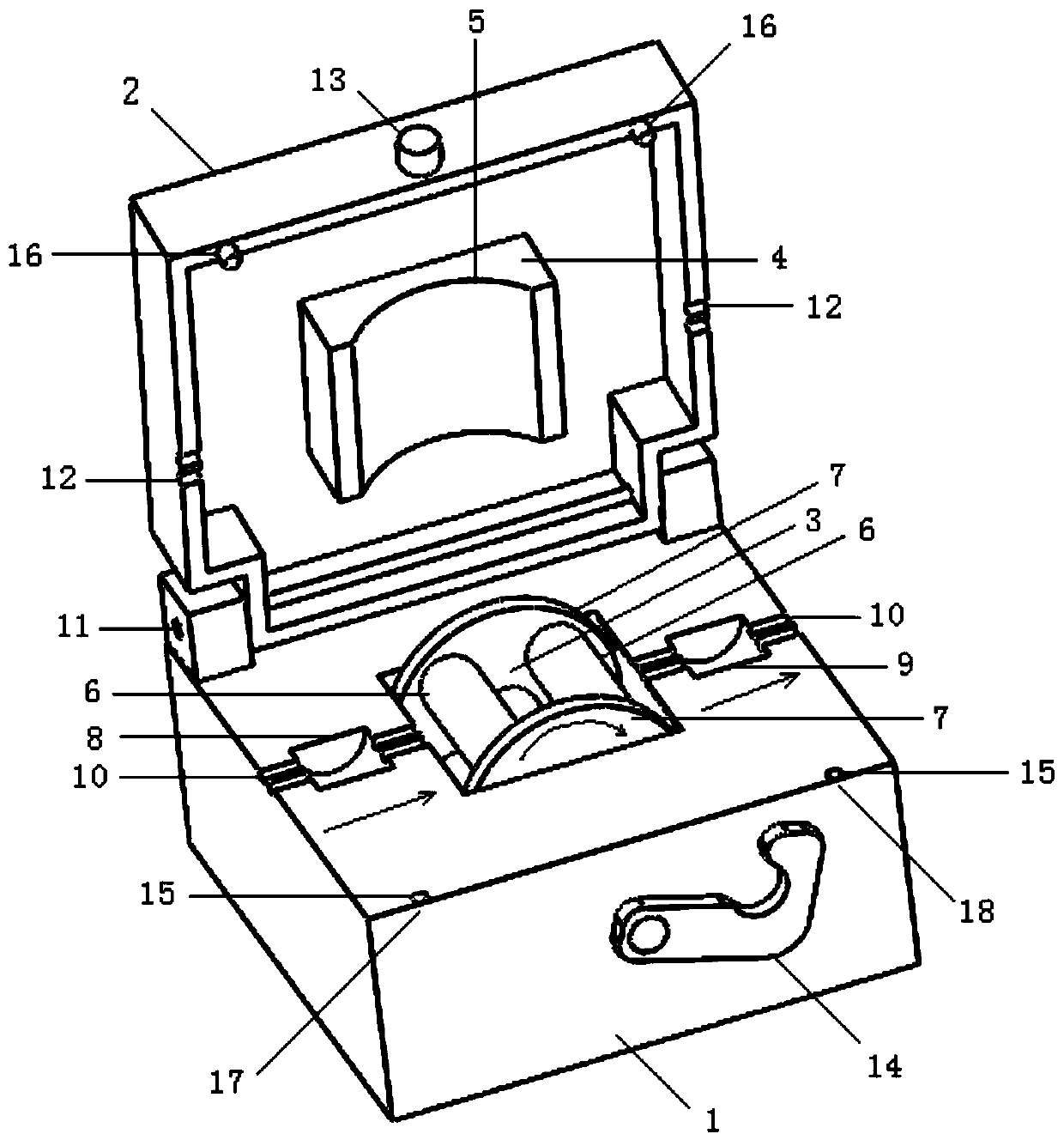

Portable car cover device which can be disposable or used for many times

PendingCN107685617ANo cleaning requiredLow costRemovable external protective coveringsEngineeringStructural engineering

The invention discloses a portable car cover device which can be disposable or used for many times, and aims at solving the phenomena that existing car cover is inconvenient to use, operate and wash and blocked easily when accommodated. The portable car cover device comprises a car cover box and hooking clamp grooves, the car cover box is provided with a car cover box device and a car cover clampplate, the outside of the car cover box device and the car cover clamp plate are provided with clamp strips relates to the hooking clamp grooves, the car cover box device is internally provided with afixed hollow shaft, the outer wall of the hollow shaft is provided with a middle shaft fixed rotary drum internally provided with a rotary shaft, the outer wall of the middle shaft fixed rotary drumis provided with a car cover winding drum, one end of the hollow shaft is provided with a mobile control handle, the cavity of the other end of the hollow shaft is provided with a telescopic rod of which one end is provided with a related grip, the car cover winding drum winds the disposable car cover, the side face of the car cover box is provided with a mobile cover plate, the car cover box is internally provided with a mobile tooth door of which the two ends are provided with guide wheels, and the mobile tooth door is provided with a related baffle.

Owner:深圳大行同宇科技有限公司

A method of chipping in grooves of electronic products

The invention relates to a surface-mounting method in a groove of an electronic product. The method comprises the steps of firstly, performing die cutting on patches pasted on a substrate so that the patches are die-cut into set shapes and the substrate is enabled to be complete, wherein distances are reserved among the patches on the substrate; laying carriers on surfaces of the patches, and simultaneously pasting the carriers on the surfaces of all patches after die cutting; performing die cutting on each carrier so that a carrier film is correspondingly formed on a surface of each patch, and enabling the size of the carrier film to be corresponding to the internal size of the groove of the electronic product, wherein the size of the carrier film is simultaneously larger than the size of the patch; tearing the carrier film with the patch from the substrate, allowing a bonding surface of the patch to face downwards, enabling the carrier film to be aligned to a frame of the internal groove of the electronic product, and pasting the patch and the carrier film in the groove of the electronic product; and taking the carrier film from the surface of the patch, and completing surface mounting in the groove of the electronic product, wherein only the patch is pasted in the groove. Compared with the prior art, the method has the advantages that the production efficiency can be improved, and the rejection ratio of the product is reduced.

Owner:HANGZHOU HAIZE ELECTRONICS TECH CO LTD

Reusable portable disposable car cover box

PendingCN111114260AEasy to useNo cleaning requiredRemovable external protective coveringsMechanical engineeringAutomotive engineering

The invention discloses a reusable portable disposable car cover box, which is characterized by comprising a car cover shell and a disposable car cover, wherein the car cover shell is provided with acover outlet; the car cover shell is provided with a clamping groove; the clamping groove is provided with a film clamping handheld rod and a film clamping rod; the car cover shell is provided with afixed stress shaft; the fixed stress shaft is provided with a speed reducing device; a car cover shaft is arranged outside the speed reducing device; the car cover shaft is provided with a bearing device; the car cover shaft is provided with the disposable car cover; the car cover shell is provided with a movable cover plate; and the car cover shell is provided with a crank.

Owner:深圳大行同宇科技有限公司

A plywood film coating process and auxiliary device

The present application relates to a plywood film covering process and auxiliary device, and relates to the field of plywood production, which includes the following steps: Step 1, making a limit frame according to the size of the plywood; Step 2, installing the plywood in the limit frame; Step 3 1. Apply wood glue on the surface of the plywood, and then cover the decorative film; step 4, scrape off the air bubbles and excess wood glue between the decorative film and the plywood; step 5, separate the plywood and the limit frame, and cover the film The finished plywood is allowed to air dry. The present application has the effect of improving that the wood glue will flow to the side of the plywood after being scraped out.

Owner:漳州市桥头木业有限公司

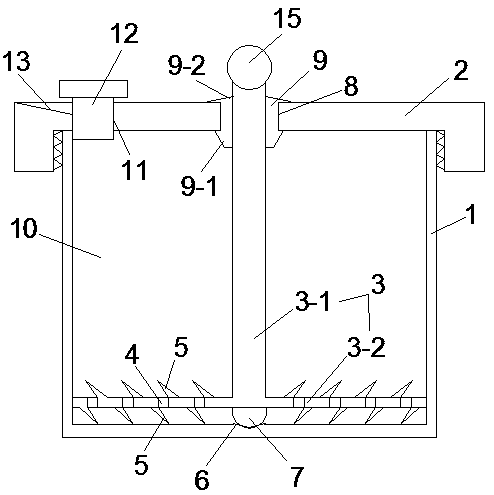

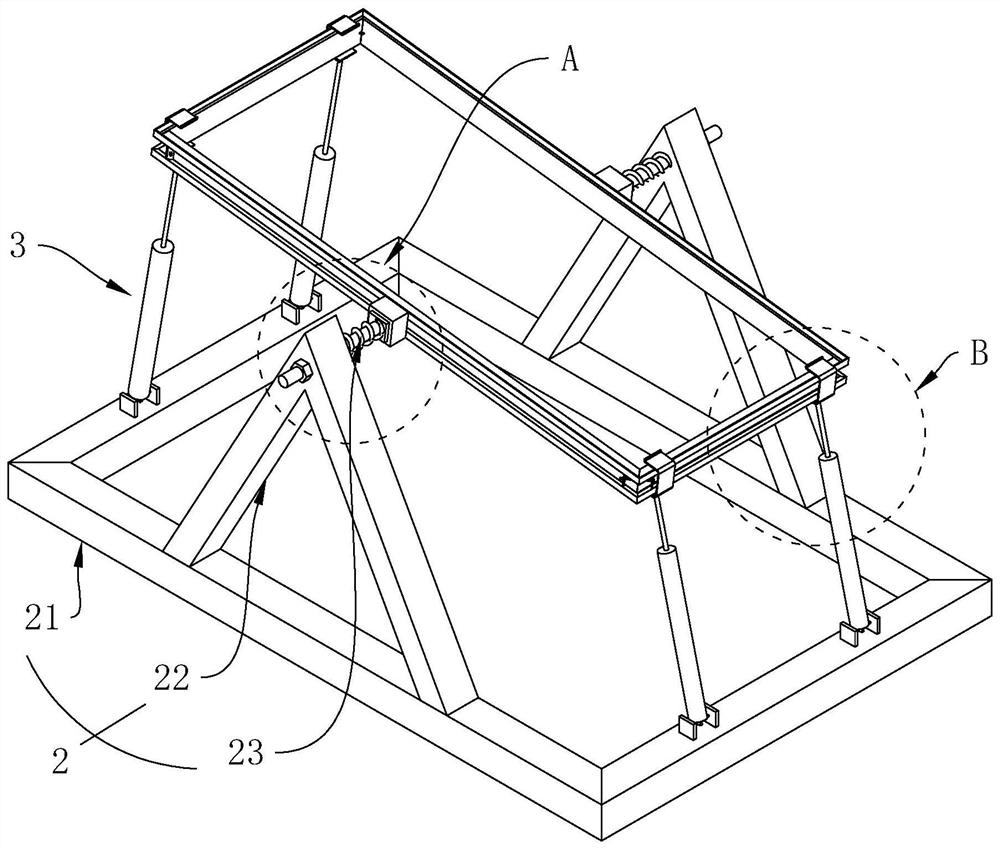

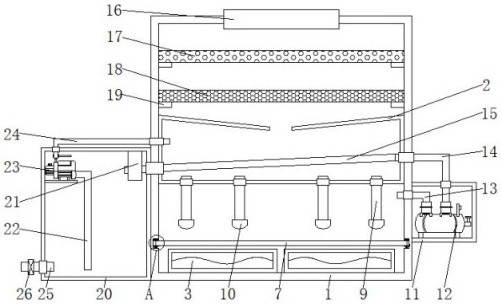

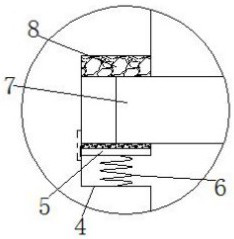

Evaporator for wastewater evaporation

InactiveCN111606485AEvaporation does not affectAvoid direct contactTreatment involving filtrationMultistage water/sewage treatmentWater storageThermodynamics

The invention discloses an evaporator for wastewater evaporation and belongs to the technical field of wastewater evaporators. The evaporator comprises a treatment box; a water storage frame is fixedly connected between the two sides of the inner wall of the treatment box; heating pipes are installed on the two sides of the bottom of the inner wall of the treatment box correspondingly; U-shaped grooves are formed in the bottoms of the two sides of the inner wall of the treatment box correspondingly; extrusion plates are slidably connected to one sides of the inner walls of the two U-shaped grooves correspondingly; and extrusion springs are fixedly connected to the bottoms of the two extrusion plates correspondingly. According to the evaporator for wastewater evaporation, a anti-scaling heat conduction plate is adopted, so that the heating pipes are prevented from directly contacting wastewater, and the evaporation of the wastewater is not influenced, and therefore, the surfaces of theheating pipes will not be scaled, and the normal use of the heating pipes can be guaranteed; the anti-scaling heat conduction plate can be conveniently disassembled and assembled through the arrangement of devices such as the extrusion plates and the extrusion springs, so that the anti-scaling heat conduction plate can be replaced after being used, the whole equipment does not need to be cleaned and disassembled, and the evaporator is more convenient to use.

Owner:安徽春辉环保工程科技有限公司

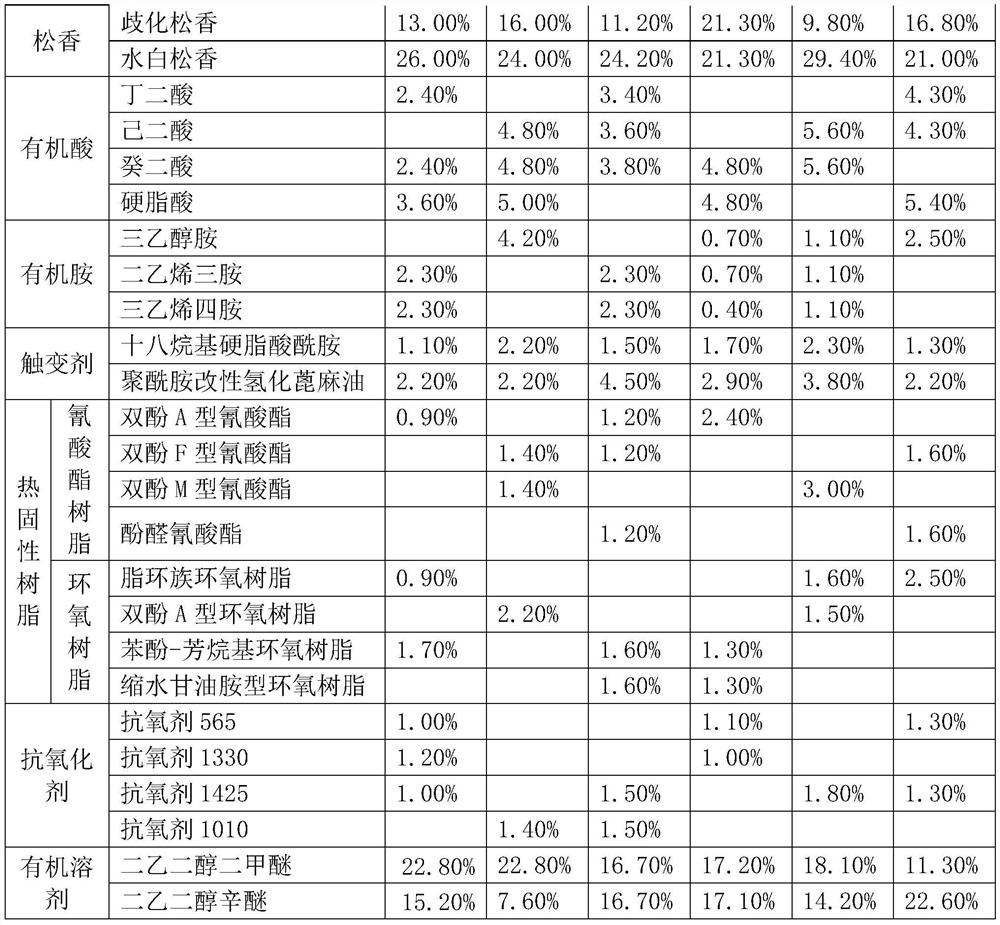

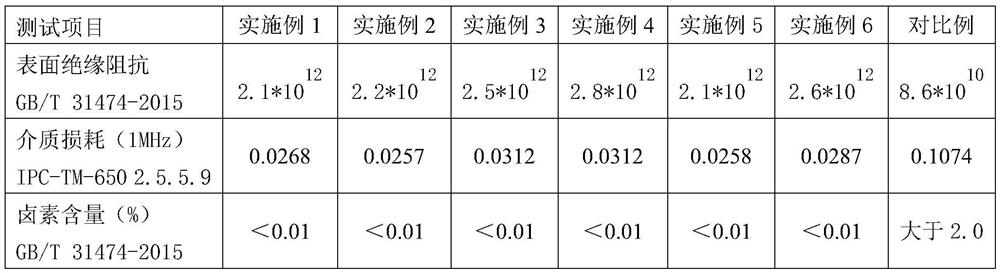

A kind of solder paste with low dielectric loss and high reliability and preparation method thereof

ActiveCN111590235BImprove adhesionExcellent dielectric propertiesWelding/cutting media/materialsSoldering mediaIndiumOrganosolv

The invention discloses a solder paste with low dielectric loss and high reliability and a preparation method thereof. The technical solution is: 85.4-91.6wt% solder alloy powder, 8.4-14.6wt% flux, wherein the tin powder includes 2.5-4.1 wt% silver, 0.5‑2.6wt% copper, 6.5‑8.7wt% indium, 3.1‑4.7wt% zinc, 0.11‑0.25wt% molybdenum, 0.09‑0.19wt% vanadium, 0.08‑0.21wt% lutetium and the rest of tin, the flux includes 35.4‑42.6wt% rosin, 8.4‑14.6wt% organic acid, 1.8‑4.6wt% organic amine, 3.3‑6.1wt% thixotropic agent, 3.5‑6.8 wt% of thermosetting resin, 1.4-3.2wt% of antioxidant and the balance of organic solvent, the thermosetting resin is composed of 48-56wt% of cyanate resin and 44-52wt% of epoxy resin. There will be no corrosive residue on the board, and the prepared solder paste has low residue, low dielectric loss, high surface insulation resistance after soldering, and high reliability solder paste, which is suitable for use in 5G-related application scenarios.

Owner:中山翰华锡业有限公司

Bathing device with water heating and heat recycling functions

InactiveCN106959027AAvoid easy cloggingTo achieve the purpose of energy savingFluid heatersStationary tubular conduit assembliesElectricityWastewater

The invention provides a bathing device with water heating and heat recycling functions. The bathing device comprises a platform basin, a water heater and a plastic sleeve type heat exchanger, and is characterized in that the plastic sleeve type heat exchanger is mounted at the lower part of the platform basin; bathing wastewater firstly flows through a stainless steel corrugated tube in the plastic sleeve type heat exchanger to be discharged into the sewer, tap water firstly flows into the plastic sleeve type heat exchanger, performs heat exchange with bath water through the tube wall of the stainless steel corrugated tube, and then flows into the water heater to be heated to a set temperature; compared with the conventional electric water heater for hot water supply, the bathing device has the advantage that the electricity is economized by 70% or above; waste hot water flows in the stainless steel corrugated tube with the diameter of 25-60 mm in the plastic sleeve type heat exchanger, so that the flow channel is not easy to block and does not need to be cleaned. According to the bathing device with water heating and heat recycling functions, the installation is simple, water is ready to be heated when the device is switched on, the water temperature is constant and comfortable, and general popularization and application are facilitated.

Owner:刘洋豪

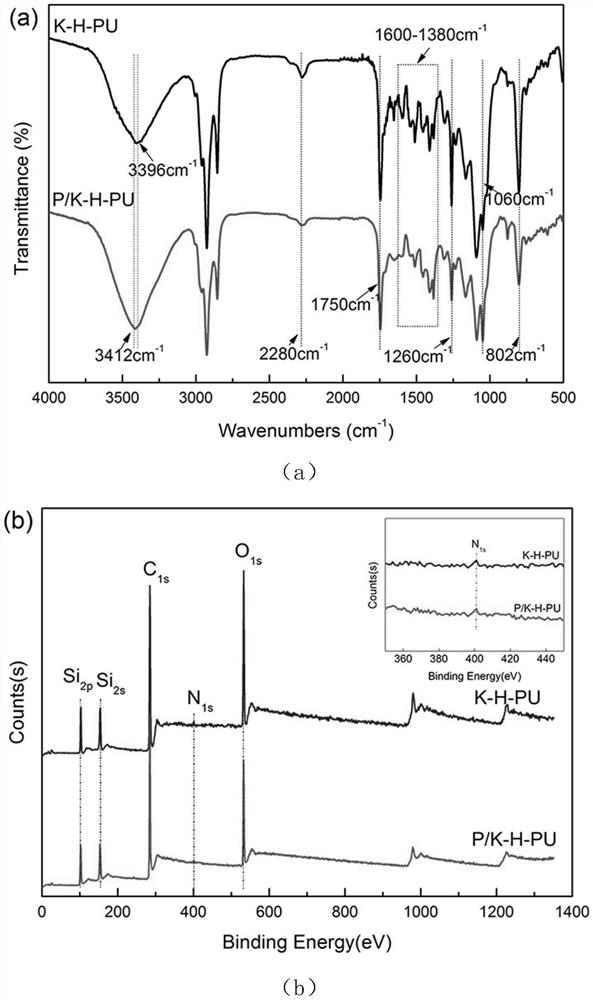

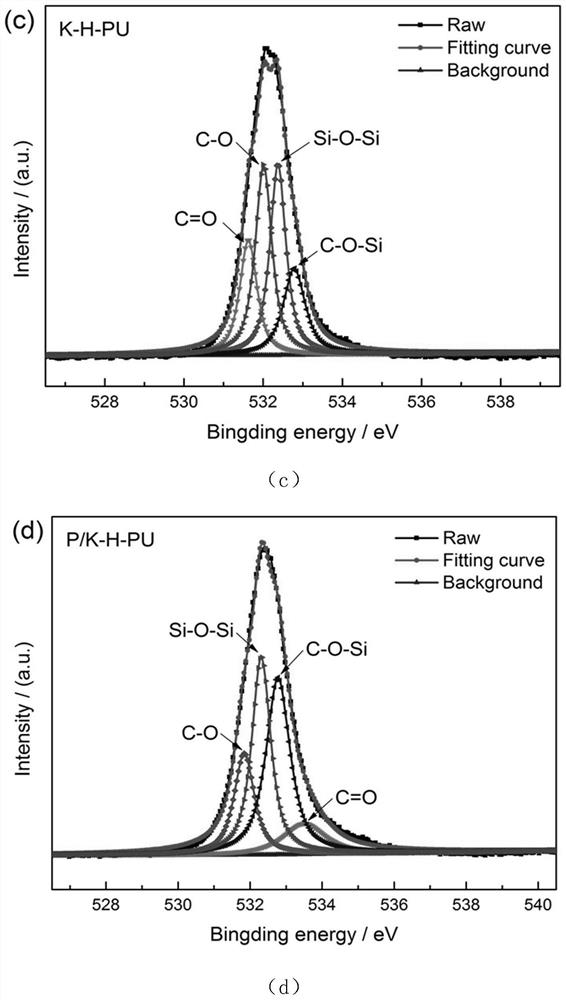

A kind of preparation method of ultra-tough bio-based polyurethane composite material

ActiveCN111499827BExpand sourceIncrease productionPolyurea/polyurethane coatingsPolymer scienceOrganosolv

The invention discloses a preparation method of a super-tough bio-based polyurethane composite material. Carry out according to the following steps: a. modify the purified waste oil with peracetic acid and ethylene glycol in turn to obtain alcoholized oil; b. fully dissolve the toughening agent in a volatile organic solvent to obtain a toughening agent solution; c. Mix alcoholized oil and silicone, place in an oil bath for magnetic stirring, then add toughening agent solution until the organic solvent is completely volatilized, then add crosslinking agent to continue the reaction; after the reaction is completed, the product is solidified to obtain the product. The present invention breaks through the limitation of the traditional single modification on the performance improvement of the polyurethane material, overcomes the pollution of the product by the solvent, the difficulty of material degradation, etc., and realizes the improvement of multiple properties of the polyurethane material. At the same time, by regulating the internal mosaic structure of the polyurethane composite material, A "green" super-tough polyurethane composite material with excellent comprehensive performance is prepared, and a method for preparing a composite material that is environmentally friendly, multifunctional and easy for industrial production is provided.

Owner:GUIZHOU UNIV

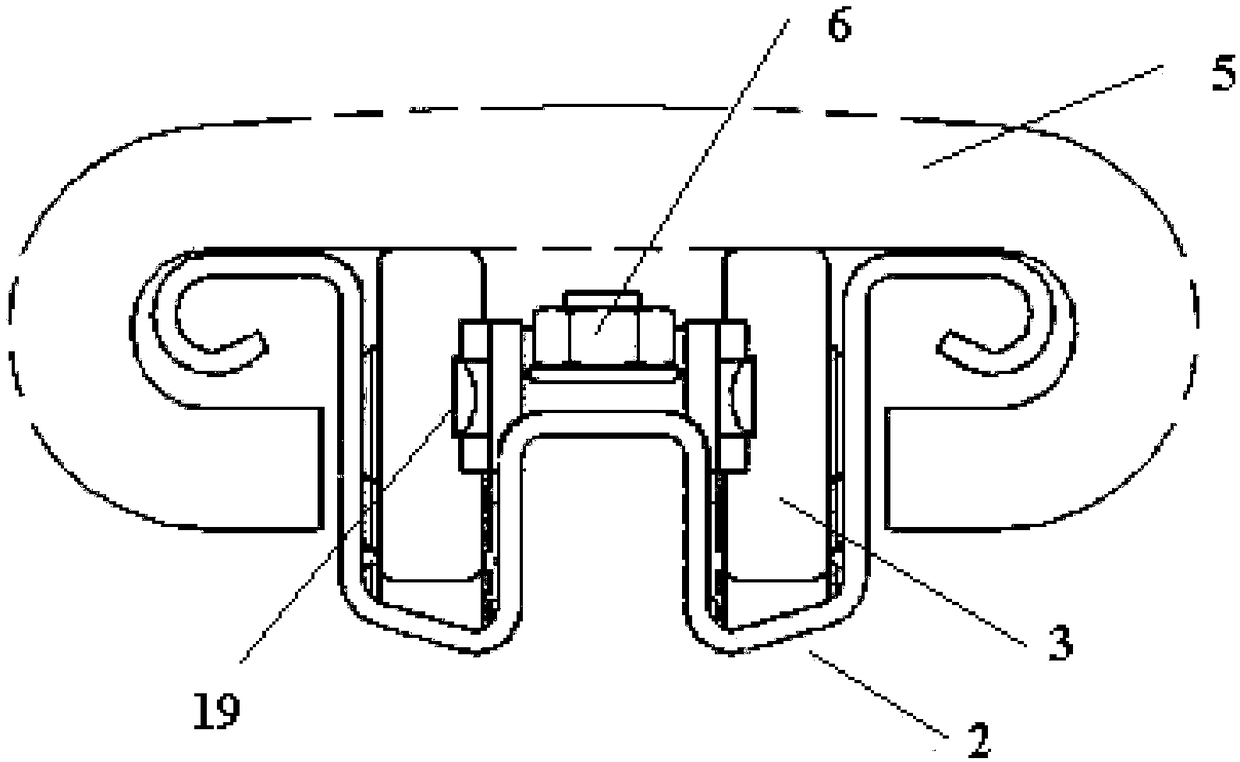

A device for realizing flow balance control by using a flow balance peristaltic pump

ActiveCN106581792BEasy to useWith flow balancing functionFlexible member pumpsDialysis systemsPeristaltic pumpEngineering

The invention relates to a flow balancing peristaltic pump for blood purification, comprising a base, an upper cover, a first pump pipe, a second pump pipe, a pump head, two balance cavities, and diaphragms; the upper cover covering the base is rotationally fitted to the base, a pump head cavity is arranged in the base, the pump head arranged in the vertical direction is placed in the pump head cavity, the upper cover is provided with a pump head cover used for covering the pump head, the first pump pipe and the second pump pipe are placed transversely in the base, both part of the first pump pipe and part of the second pump pipe compress the peripheral side of the pump head, two sides of the pump head are provided with a limiting plate for limiting the movement of the first and second pump pipes, each balance cavity is internally provided with one diaphragm for diving the balance cavity into a first cavity and a second cavity, the first pump pipe is communicated with the corresponding first cavity, the second pump pipe is communicated with the corresponding second cavity, and the two balance cavities are positioned on two sides of the pump head. The flow balancing peristaltic pump has flow balancing function and belongs to the technical field of blood purification.

Owner:GUANGZHOU UNIVERSITY

Spiral carbon fiber composite ceramics for activating water and its production method and application

The invention discloses helical carbon fiber composite ceramic for water activation. The helical carbon fiber composite ceramic comprises a ceramic phase and helical carbon fibers, wherein the helical carbon fibers are distributed and loaded on the ceramic phase. By using the helical carbon fibers, the harmful substance fluctuation can be changed to be fluctuation matched with human bodies. To be specific, sub-micron helical carbon fibers and the ceramic raw material are compounded and then subjected to oxygen insulation sintering, so as to obtain the composite ceramic. The composite ceramic can change the fluctuation harmful to the human bodies and generated by multiple chemical substances, element chlorine, harmful bacteria and the like into fluctuation beneficial to bodies, and enables water molecules to be subjected to declension vibration activation, so that water molecules are changed into smaller molecular clusters and the blood flow volume of human brains is increased obviously; in addition, through the special fluctuation, the effect of inhibiting bacterium reproduction is realized. On the basis of a fluctuation effect, all needed is to add a small amount of the helical carbon fiber composite ceramic, and thus the water quality can be changed instantly. In a water activation treatment process, pollutants are not adsorbed, and chemical changes do not occur, so that later cleaning and maintenance are not required and the helical carbon fiber composite ceramic disclosed by the invention can be used for a long time.

Owner:泉州凯佳新材料研究院有限公司 +2

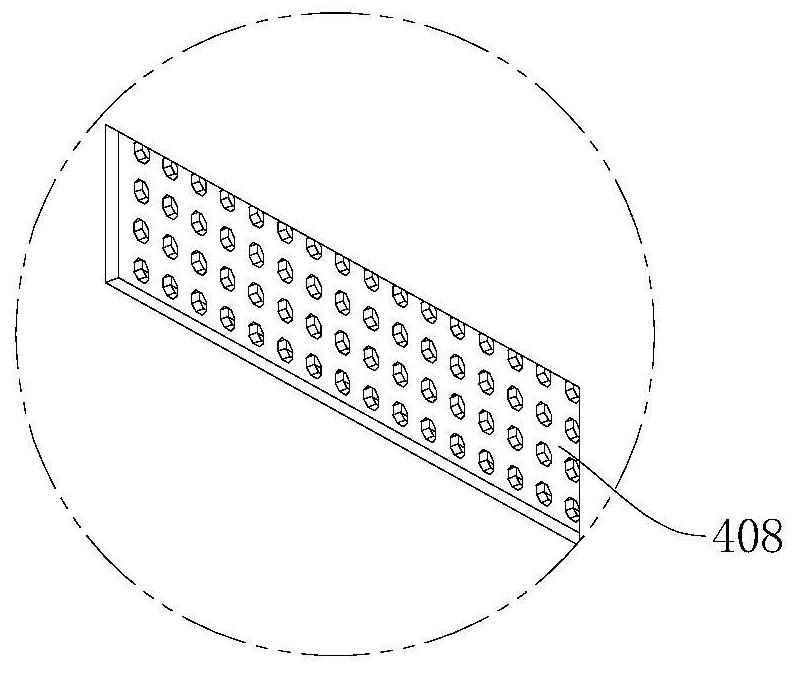

Moving handrail guiding assembly of guardrail column part of escalator or moving walking escalator

The invention discloses a moving handrail guiding assembly of a guardrail column part of an escalator or a moving walking escalator. The moving handrail guiding assembly comprises a supporting formingpiece, and a low-friction-coefficient component or a low-friction-coefficient subcomponent chain, wherein the supporting forming piece is mounted on the guardrail column part and provided with a chamber defined by the side walls and the bottom; and the two ends of the low-friction-coefficient component or the low-friction-coefficient subcomponent chain are fixed to the guardrail column part, thelow-friction-coefficient component comprises a single component, the low-friction-coefficient subcomponent chain comprises a plurality of low-friction-coefficient subcomponents, the low-friction-coefficient component or each low-friction-coefficient subcomponent has the shape matched with the shape of the chamber of the supporting forming piece, and the ends of all the low-friction-coefficient subcomponents are connected mutually to cover an opening of the chamber. The moving handrail guiding assembly is simple in structure and low in cost, heat generated by friction and heat generated by repeated bending in a handrail can be reduced, the service life of the handrail is prolonged, abrasion, aging and cracking are reduced, and meanwhile, a sensor can be used for monitoring force in the handrail and monitoring abrasion of the handrail.

Owner:KONE CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com