Hedge trimming equipment with cleaning function

A hedge trimming and functional technology, applied in the field of plant protection, can solve the problems of leaf and branch environmental pollution, single function, time-consuming and labor-intensive cleaning, etc., to achieve the effect of ensuring normal growth, improving the growing environment, and improving the aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

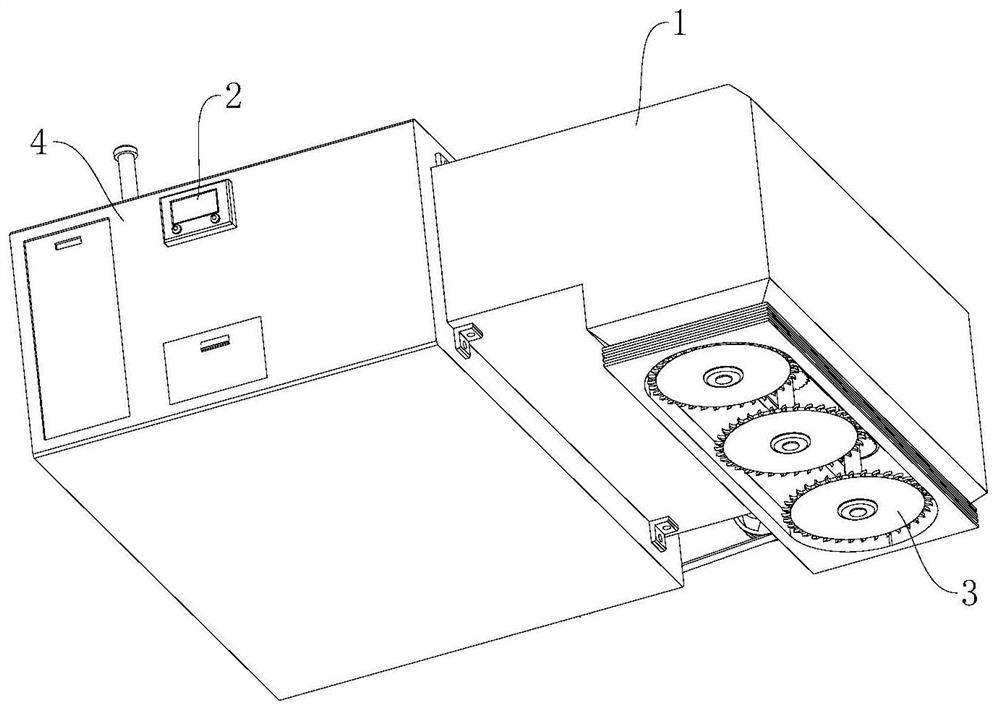

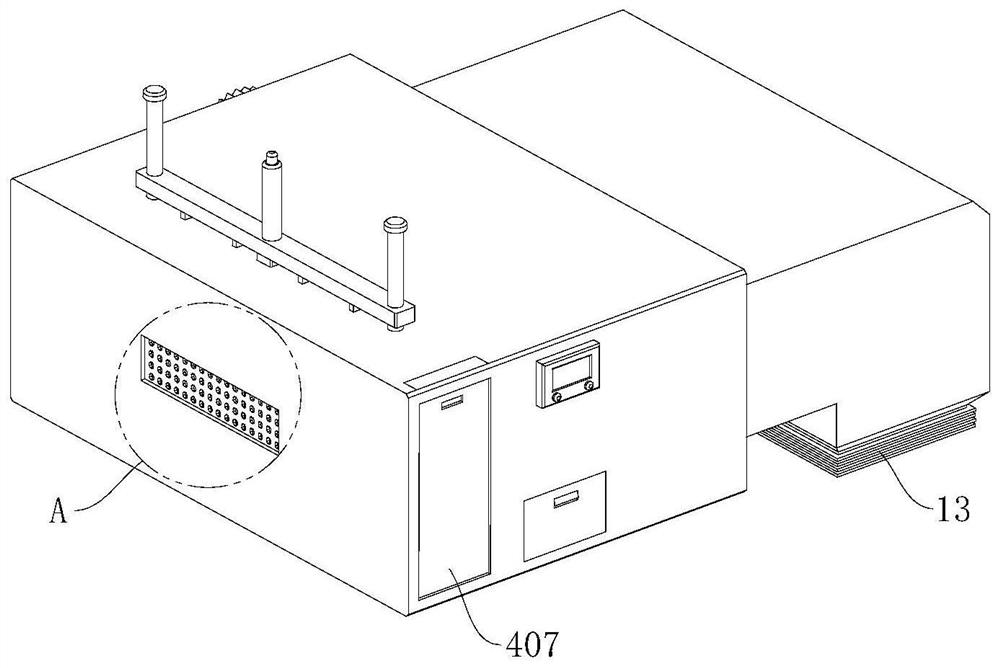

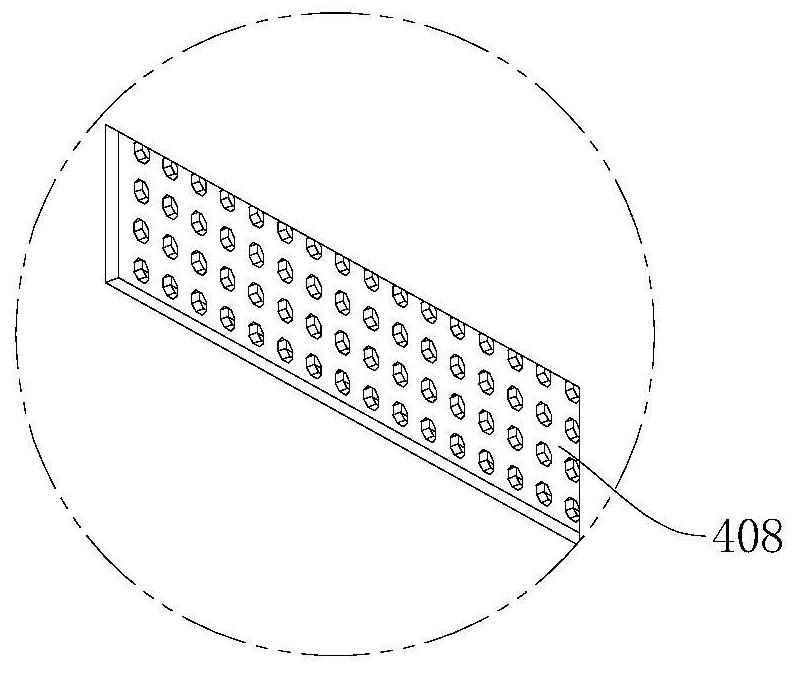

[0042] refer to Figure 1 to Figure 8 A hedge trimming device with self-cleaning function shown includes an adsorption tube 1, and also includes a controller 2, a trimming mechanism 3 and a cleaning mechanism 4, and the trimming mechanism 3 is arranged inside the adsorption tube 1 for trimming hedges , trimming mechanism 3 comprises driving assembly 30 and three rotating blades 31, and described driving assembly 30 is arranged on the inside of adsorption pipe 1, and three rotating blades 31 are equally spaced to insert on the inner wall of adsorption pipe 1, and driving assembly 30 and three Two rotary blades 31 are transmission connected, and each rotary blade 31 is located on the open end of the adsorption pipe 1, and the cleaning mechanism 4 includes a cleaning box 40, an adsorption assembly 41 and a cutting assembly 42, and the cleaning box 40 is fixedly arranged on the adsorption pipe 1. One end of the tube 1, and the cleaning box 40 communicates with the adsorption tube ...

Embodiment 2

[0053] refer to Figure 9 to Figure 10Shown is a hedge trimming device with its own cleaning function. This embodiment improves the cutting assembly on the basis of Embodiment 1. The cutting assembly 42 includes two rollers 420, several scrapers 426 and several The flying knife 427 and the two rollers 420 are arranged symmetrically inside the first chamber 400, and the two ends of each roller 420 are rotatably connected to the inner wall of the cleaning box 40 through a plug-in column, and several scrapers 426 are arranged at equal intervals On the outer walls of the two drums 420, each flying knife 427 is hingedly arranged at the end of each scraper 426 away from a drum 20. When the two drums 420 follow the first gear 422 and the second gear 425 to rotate at a high speed, All the scrapers 426 on the outer wall of each cylinder 420 are all forced to rotate at a high speed, thus making each scraper 426 stir the air inside the second chamber 401, when one scraper 426 on one roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com