Room-temperature self-repairing ionic gel as well as preparation method and application thereof

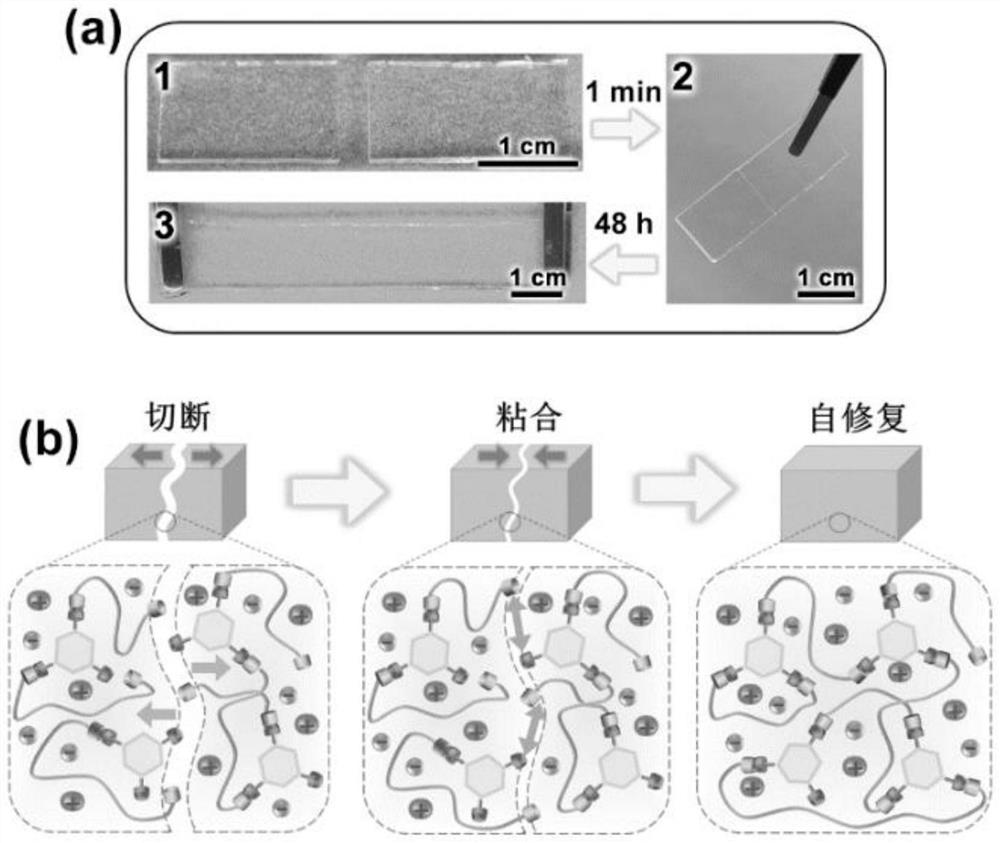

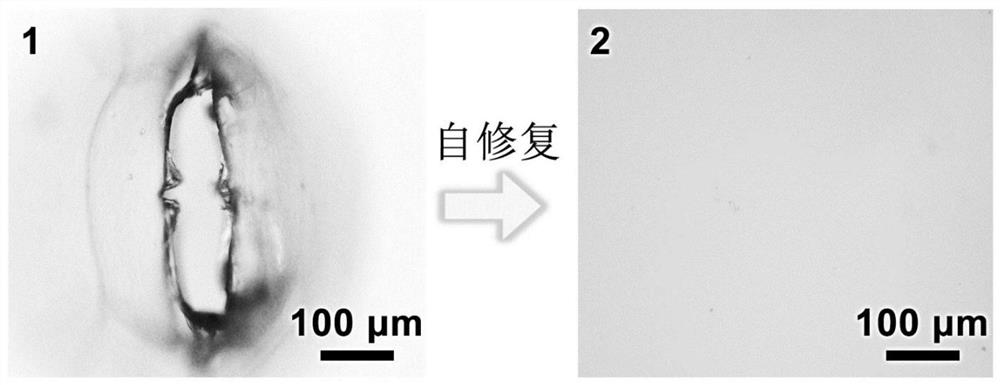

An ion gel, self-healing technology, applied in separation methods, chemical instruments and methods, semi-permeable membrane separation, etc., can solve the problem that the thickness of self-healing ion gel cannot be reduced to 100 microns, poor mechanical strength, low permeability problems, to achieve the effect of restoring structural integrity and carbon dioxide separation capacity, improving service life, improving service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

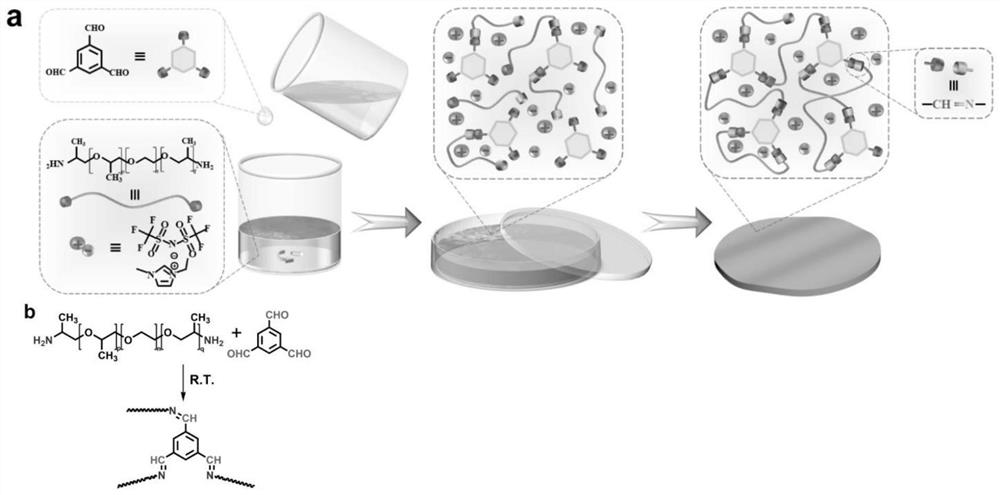

[0036] The invention provides a preparation method of room temperature self-repairing ion gel, comprising the following steps:

[0037] Mix diamino-terminated oligomers, ionic liquids, trialdehyde-based cross-linking agents and organic solvents, perform the first Schiff reaction in an ice-water bath, and then perform the second Schiff reaction at room temperature under sealed conditions to obtain room temperature self-healing ions gel.

[0038] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0039] The raw materials used in the present invention, diamino-terminated oligomers and ionic liquids are stored in a desiccator at 25°C and 10% RH, the trialdehyde-based cross-linking agent is stored in a low temperature environment (2°C), and the rest of the reagents are stored at room temperature in environment.

[0040] The invention mixes diamino-terminated oligome...

Embodiment 1

[0069] H 2 N-PPG-PEG-PPG-NH 2 (M n =500~1900, 0.15g) and ionic liquid [EMIm]TFSI (0.15g) were dissolved in 7.5mL organic solvent THF, using a magnetic stirrer, stirred at a constant speed of 500rpm for 1h, completely dissolved, and a mixed solution was obtained;

[0070] Weigh 8.11mg of BTC and dissolve in THF to prepare 20mg·mL -1 Uniform clear and transparent solution to obtain a crosslinking agent solution;

[0071] In an ice-water bath, drop the cross-linking agent solution into the mixed solution drop by drop, use a magnetic stirrer to stir and mix evenly at a stirring speed of 500 rpm, react the obtained reaction solution for 4 hours under the condition of an ice-water bath, and cast the obtained transparent product on glass In a watch glass, seal the reaction at room temperature (25°C, 20%RH) for 72h; after the reaction, dry the obtained product at room temperature (25°C, 20%RH) for 48h, then place it in a room temperature vacuum desiccator After drying for 48 hours...

Embodiment 2

[0073] H 2 N-PPG-PEG-PPG-NH 2 (M n =500~1900, 0.15g) and ionic liquid [EMIm]TFSI (0.225g) were dissolved in 7.5mL organic solvent THF, using a magnetic stirrer, stirred at a constant speed of 500rpm for 1h, completely dissolved, and a mixed solution was obtained;

[0074] Weigh 8.11mg of BTC and dissolve in THF to prepare 20mg·mL -1 Uniform clear and transparent solution to obtain a crosslinking agent solution;

[0075] In an ice-water bath, drop the cross-linking agent solution into the mixed solution drop by drop, use a magnetic stirrer to stir and mix evenly at a stirring speed of 500 rpm, react the obtained reaction solution for 4 hours under the condition of an ice-water bath, and cast the obtained transparent product on glass In a watch glass, seal the reaction at room temperature (25°C, 20%RH) for 72h; after the reaction, dry the obtained product at room temperature (25°C, 20%RH) for 48h, then place it in a room temperature vacuum desiccator After drying for 48 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com