High-efficiency, energy-conservation and clean method for producing chromate

A manufacturing method and technology of chromate, applied in the direction of chromate/dichromate, etc., can solve the problems of complex operation, little commercial significance, failure to realize economical operation, etc., and achieve improved reaction efficiency, easy operation, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

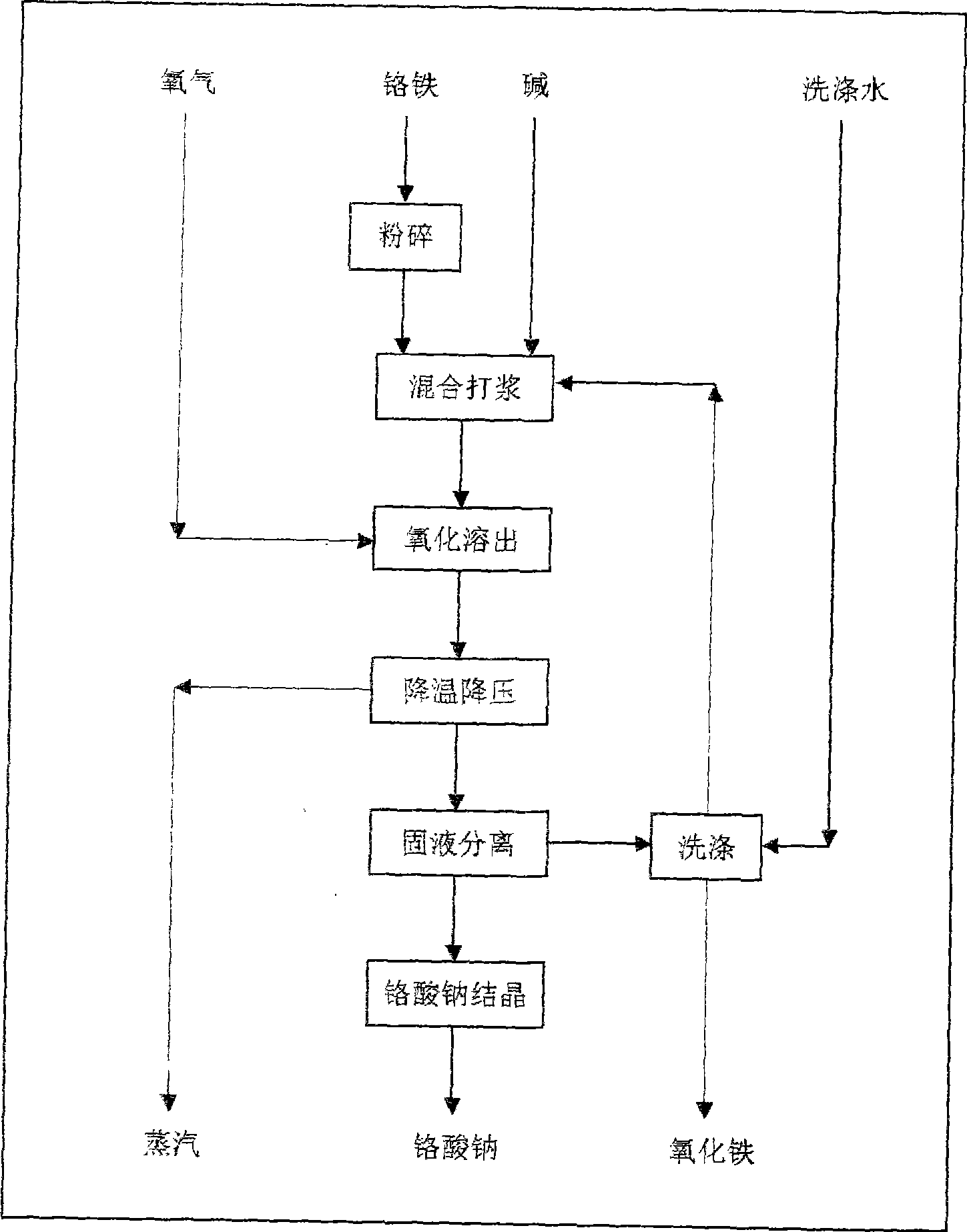

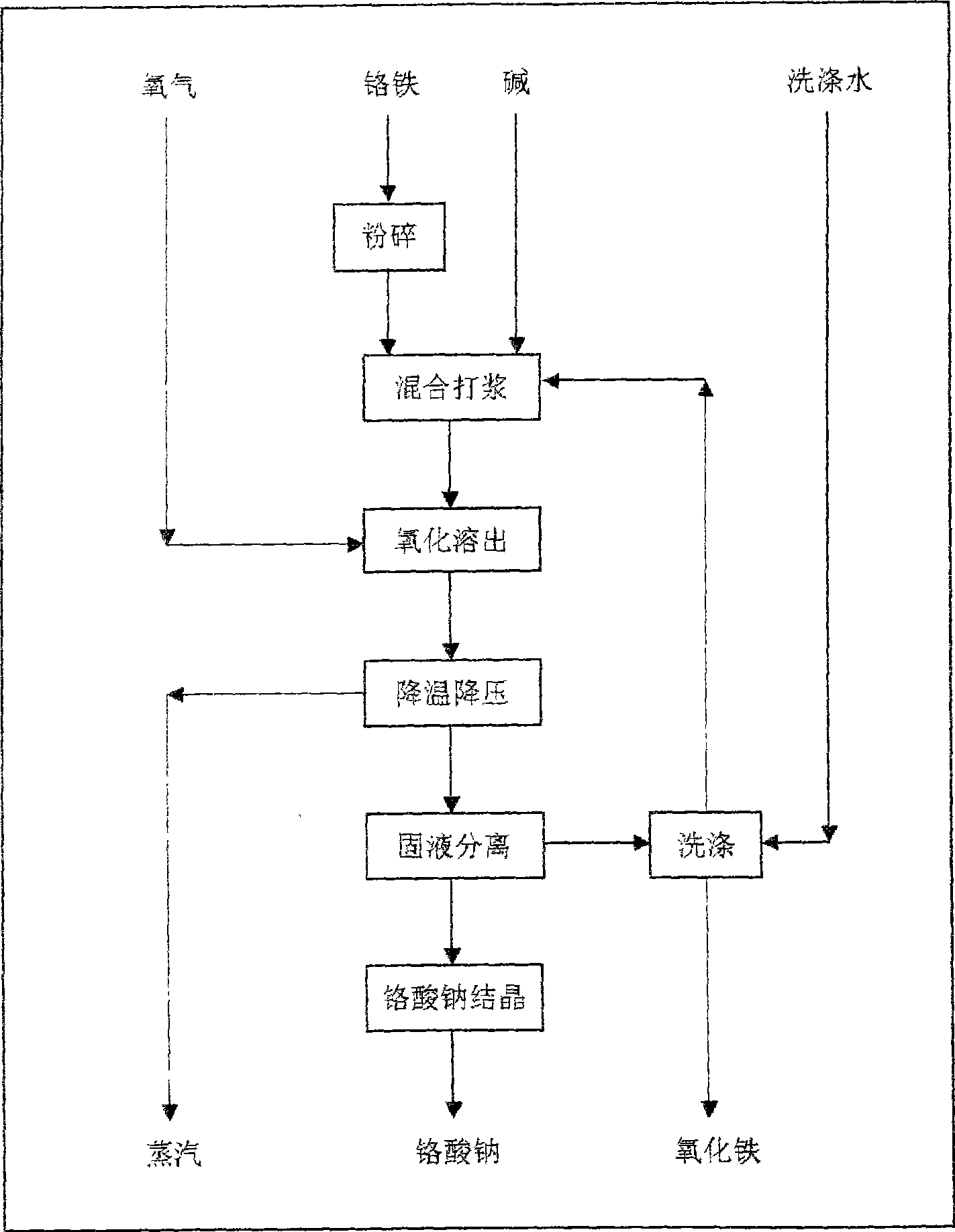

Method used

Image

Examples

example 1

[0034] Adopt ferrochrome with 60.10% chromium content, 30.40% iron content, 7.10% carbon content and 2.50% silicon content as raw material to prepare the reaction initial solution. The formula is 100g ferrochrome, 80g caustic soda, and 1000mL water, which are placed in a 3000mL reaction kettle. The cold state is filled with oxygen into the kettle, and the oxygen pressure is 3.55MP. The heating voltage is 180v, the stirring speed is 350rpm, the heating reaction is carried out at 280°C for 30 minutes, the temperature is naturally cooled to room temperature and the material is discharged, and the solid-liquid separation is carried out. The filter cake is washed many times until there is no characteristic color of hexavalent chromium, and the chromium conversion is detected. The rate is 81.52%. Obtained 49.1 g of reddish-brown dry filter cake, containing 26.11% of chromium, 69.86% of iron and 4.02% of silicon as oxides.

example 2

[0036] Adopt ferrochrome with 60.10% chromium content, 30.40% iron content, 7.10% carbon content, and 2.50% silicon content as raw material to prepare the reaction initial solution. The formula is 200g ferrochrome, 200g caustic soda, and 1000mL water, which are placed in a 3000mL reaction kettle. The cold state is filled with oxygen into the kettle, and the oxygen pressure is 7.10MP. The heating voltage is 180v, the stirring speed is 350rpm, the heating reaction is carried out, and the temperature is kept at 280°C for 10 minutes, the temperature is naturally cooled to room temperature, and the solid-liquid separation is carried out. The rate is 85.94%. Obtained 148.4 g of reddish-brown dry filter cake, containing 21.19% of chromium, 74.52% of iron and 4.29% of silicon as oxides.

example 3

[0038]Adopt ferrochrome with 60.10% chromium content, 30.40% iron content, 7.10% carbon content and 2.50% silicon content as raw material to prepare the reaction initial liquid. The formula is 200g ferrochrome, 180g caustic soda, and 500mL water, which are placed in a 3000mL reaction kettle. The cold state is filled with oxygen into the kettle, and the oxygen pressure is 5.92MP. The heating voltage is 180v, the stirring speed is 350rpm, the heating reaction is carried out at 280°C for 20 minutes, the temperature is naturally cooled to room temperature and the material is discharged, and the solid-liquid separation is carried out. The filter cake is washed many times until there is no characteristic color of hexavalent chromium, and the chromium conversion is detected. The rate is 75.86%. 111.7 g of reddish-brown dry filter cake was obtained, containing 31.59% of chromium, 64.69% of iron and 3.72% of silicon as oxides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com