Preparation method and application of epoxy resin coated stainless steel powder

An epoxy resin and stainless steel technology, applied in the field of 3D printing materials, can solve the problems of high equipment requirements and complicated preparation process of coating powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] One embodiment of the present invention provides a method for preparing epoxy resin-coated stainless steel powder, comprising the following steps:

[0030] Dissolve the epoxy resin in the solvent, add stainless steel powder, stir until the solvent evaporates, then dry, grind and sieve in sequence;

[0031] The mass ratio of epoxy resin to stainless steel powder is 1:(20-50), and the epoxy resin is solid bisphenol A epoxy resin.

[0032] Wherein, the volatilization of the stirring solvent can be understood as that the upper layer solution cannot be layered out.

[0033] It can be understood that in the preparation method of epoxy resin-coated stainless steel powder, adding a slight excess of solvent is conducive to the uniform mixing of epoxy resin and stainless steel powder; adding too much solvent will lead to too long stirring time and increase the cost.

[0034] Dissolve the solid bisphenol A type epoxy resin in the solvent, and coat the surface of stainless steel t...

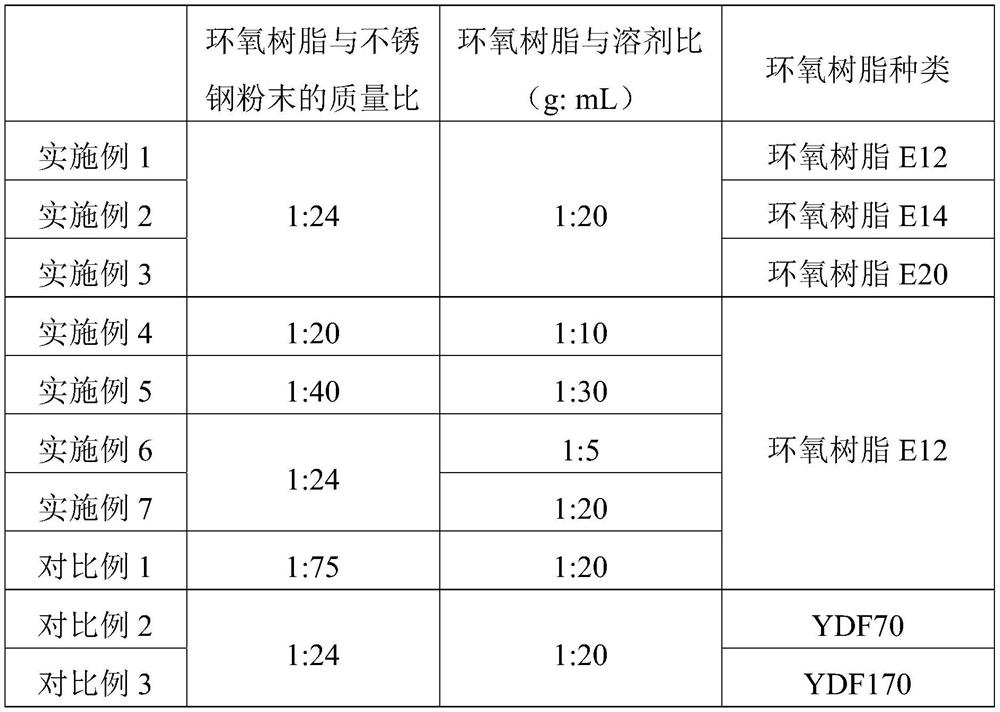

Embodiment 1

[0061] (1) Get 4g epoxy resin E12 and fully dissolve in 80mL acetone solution, add 96g D50=14 μ m, powder particle shape is the 316L stainless steel powder of nearly spherical shape in the acetone solution that is dissolved with resin;

[0062] (2) Put the beaker containing stainless steel, epoxy resin, and acetone mixture in a fume hood, and use a mechanical stirring device (model: IKA EUROSTAR 60digital) to stir the mixture at a stirring speed of 800r / min. A large amount of volatilization, when the mechanical stirring cannot fully stir the remaining materials, use a glass rod to further stir them until the mixed materials cannot be separated into the upper layer solution, and then take the beaker out of the fume hood;

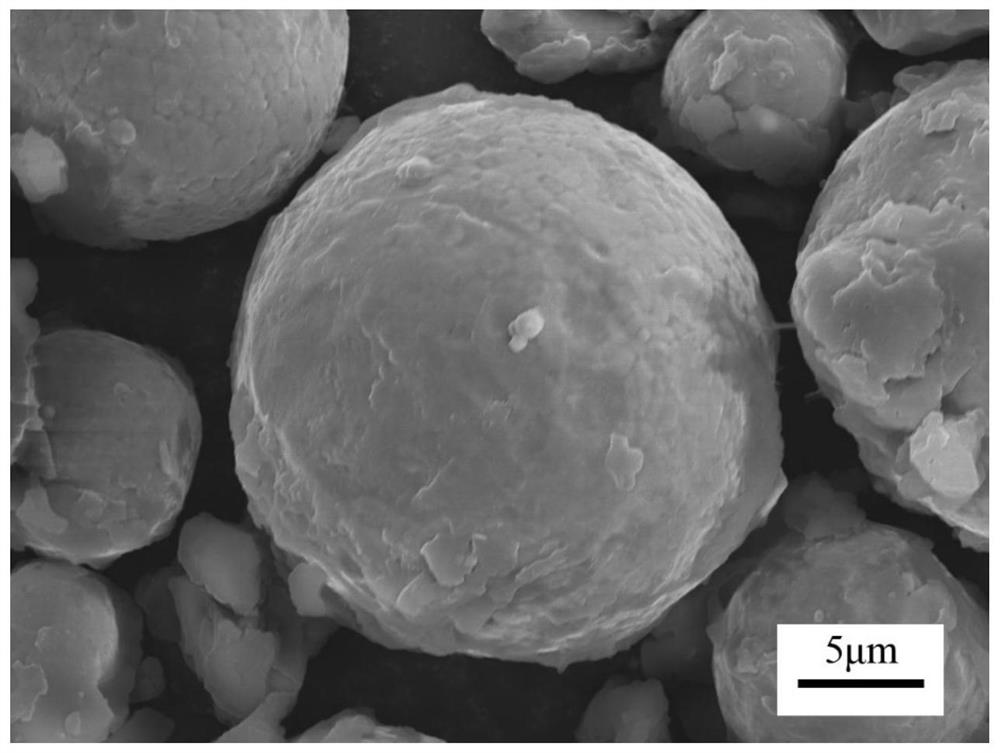

[0063] (3) Put the mixed material in a blower dryer, bake at 50°C for 1.5 hours, take it out, grind it, and sieve it with a 300-mesh sieve to obtain epoxy resin-coated stainless steel powder with good coating effect, such as figure 1 .

Embodiment 2

[0065] (1) Get 4g of epoxy resin E14 and fully dissolve in 80mL of acetone solution, add 96g of D50=14 μm, 316L stainless steel powder that is nearly spherical in shape into the acetone solution in which the resin is dissolved;

[0066] (2) Put the beaker containing stainless steel, epoxy resin, and acetone mixture in a fume hood, and use a mechanical stirring device (model: IKA EUROSTAR 60digital) to stir the mixture at a stirring speed of 800r / min. A large amount of volatilization, when the mechanical stirring cannot fully stir the remaining materials, use a glass rod to further stir them until the mixed materials cannot be separated into the upper layer solution, and then take the beaker out of the fume hood;

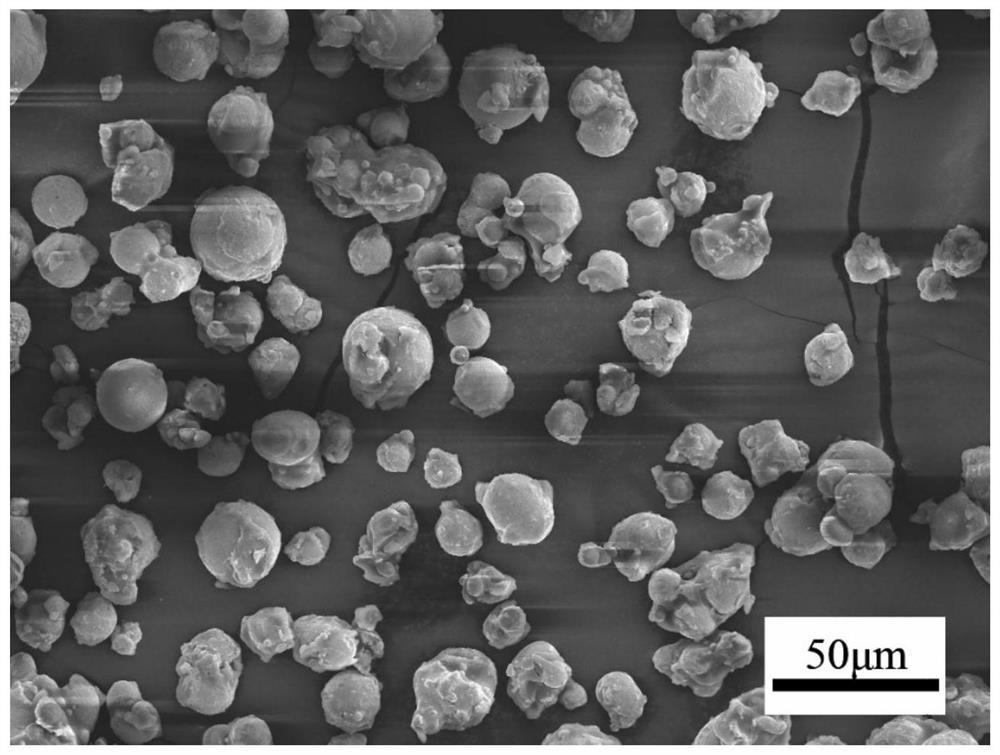

[0067] (3) Put the mixed material in a blower dryer, bake at 50°C for 1.5 hours, take it out, grind it, and sieve it with a 300-mesh sieve to obtain epoxy resin-coated stainless steel powder with good coating effect, such as figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com