A plywood film coating process and auxiliary device

An auxiliary device, plywood technology, applied in the direction of manufacturing tools, wood processing equipment, wooden veneer joints, etc., can solve the problem of flowing to the side of the plywood, etc., to reduce material costs, facilitate film covering work, improve The effect of coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

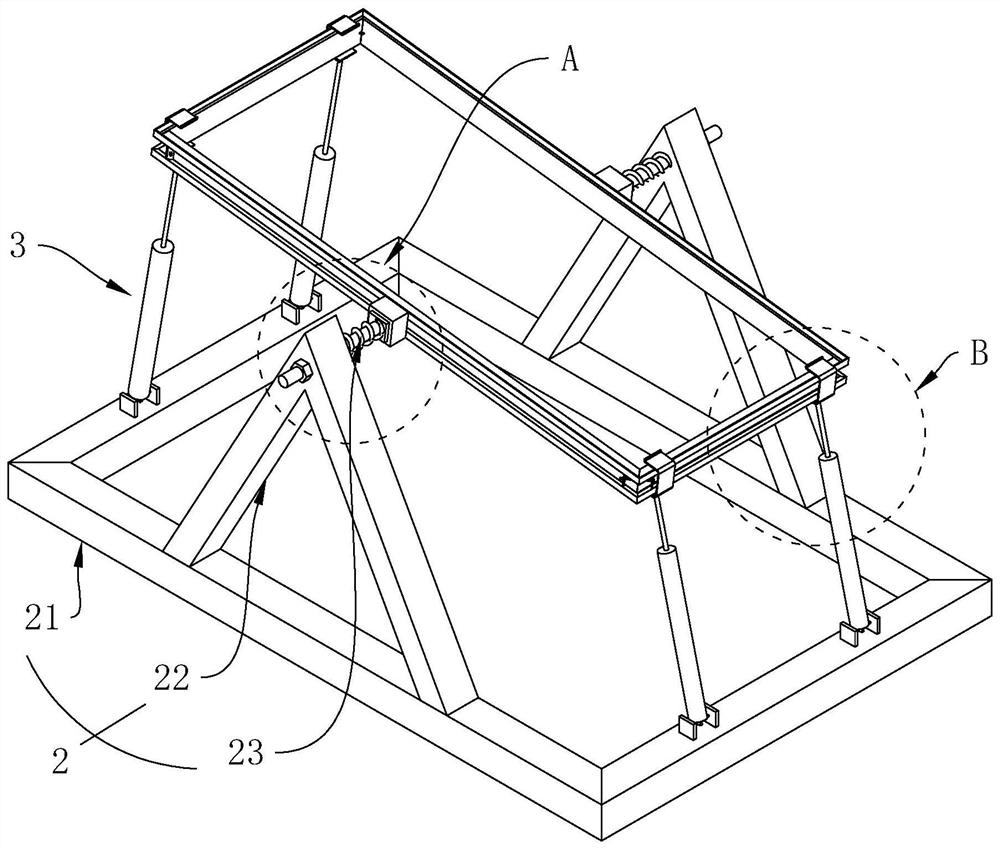

[0043] The following is attached Figure 1-6 The application is described in further detail.

[0044] The embodiment of the present application discloses a plywood coating process. The plywood coating process includes the following steps:

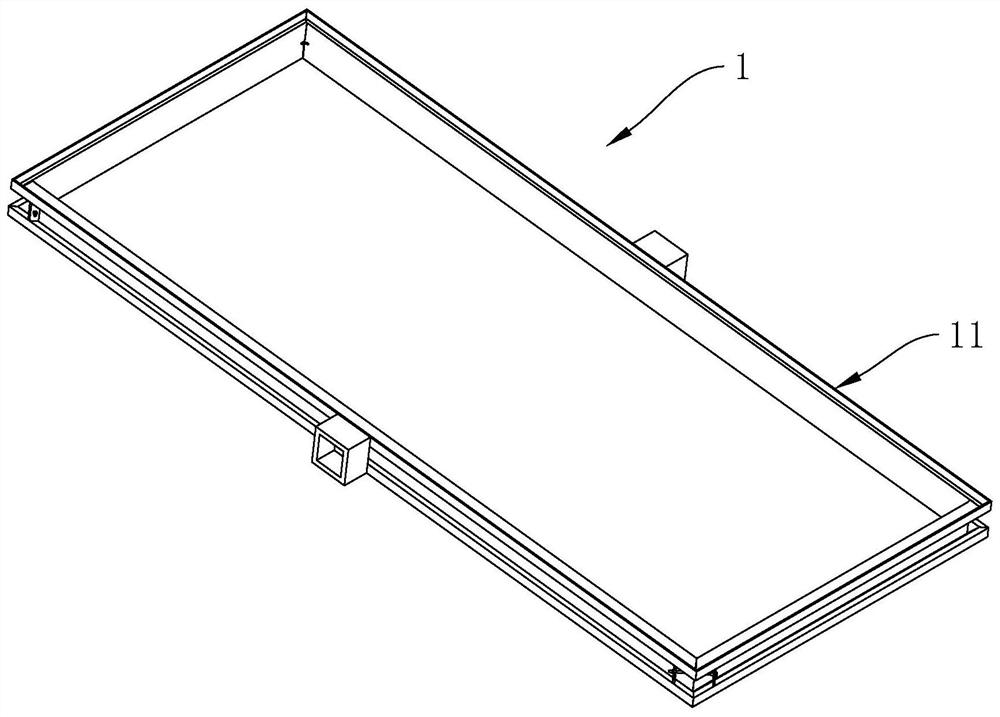

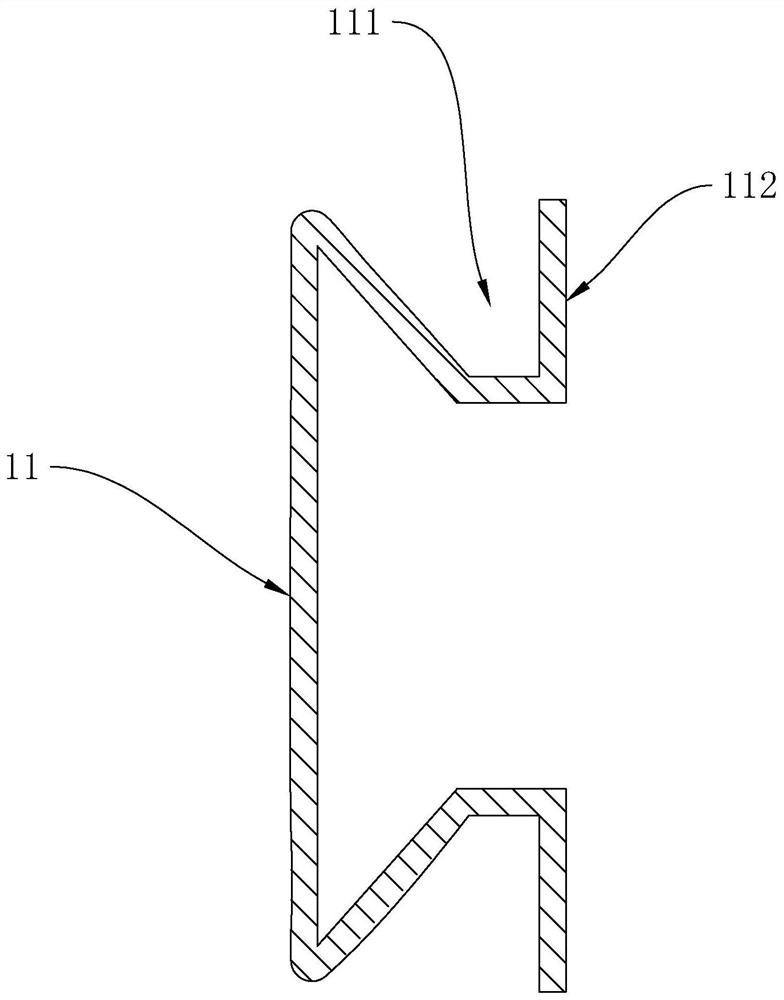

[0045] Step 1. Make the limit frame 1 according to the size of the plywood;

[0046] Step 2, the plywood is installed in the limit frame 1, the thickness of the plywood is the same as that of the limit frame 1, and each side of the plywood is closely attached to the inner side of the limit frame 1;

[0047]Step 3, coating carpentry glue on the surface of the plywood, and then covering the surface of the plywood with a decorative film;

[0048] Step 4. Use a scraper to scrape on the surface of the decorative film to scrape off the air bubbles and excess woodworking glue between the decorative film and the plywood. The woodworking glue is scraped out between the decorative film and the plywood and will fall directly to the surface of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com