Straw-collecting device of mowing machine

A lawn mower and grass collection technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of inconspicuous effect, reduced work efficiency, unfavorable staff collection, etc., to achieve overall beauty and tidiness, reduce The effect of cost expenditure and broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

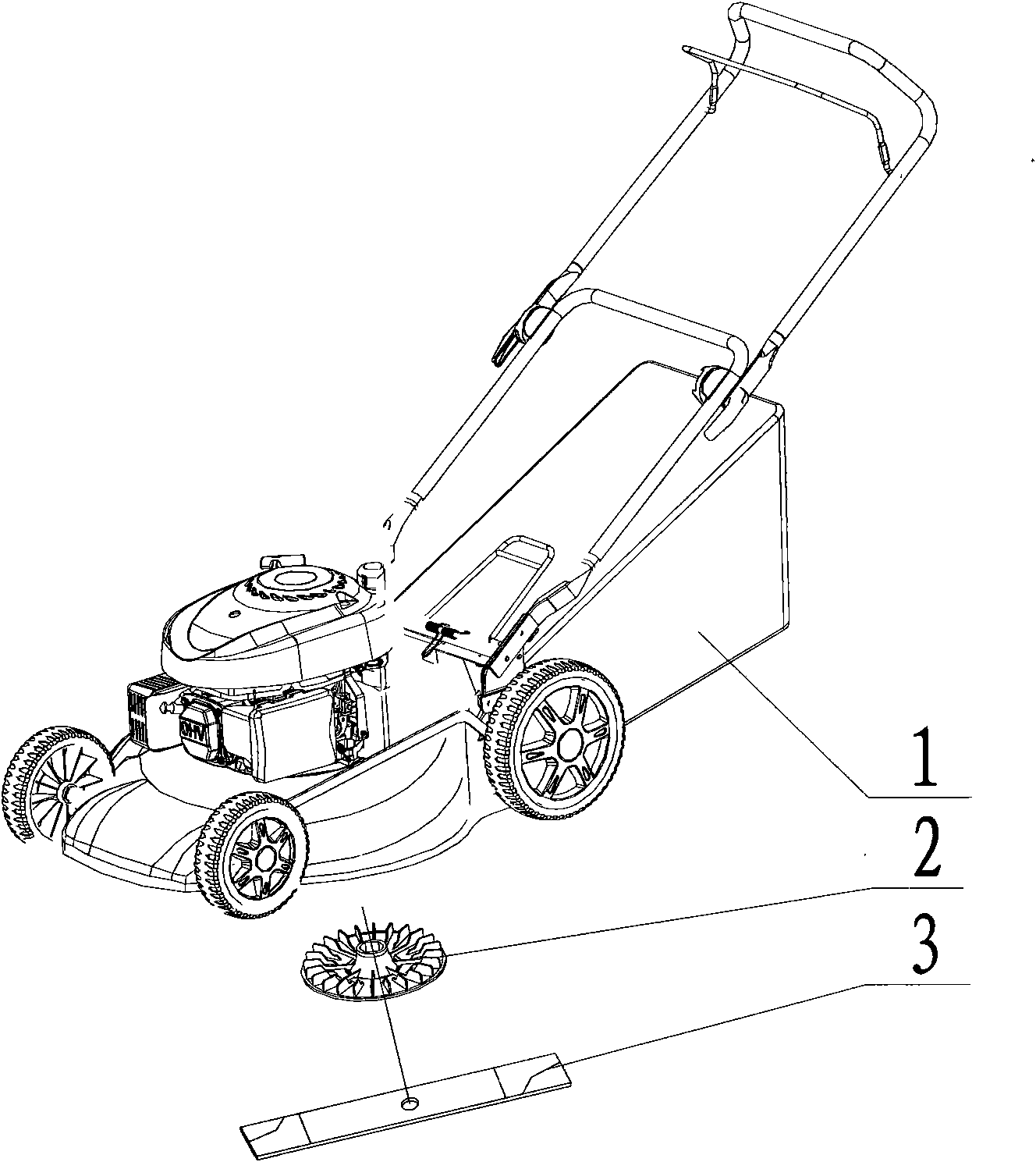

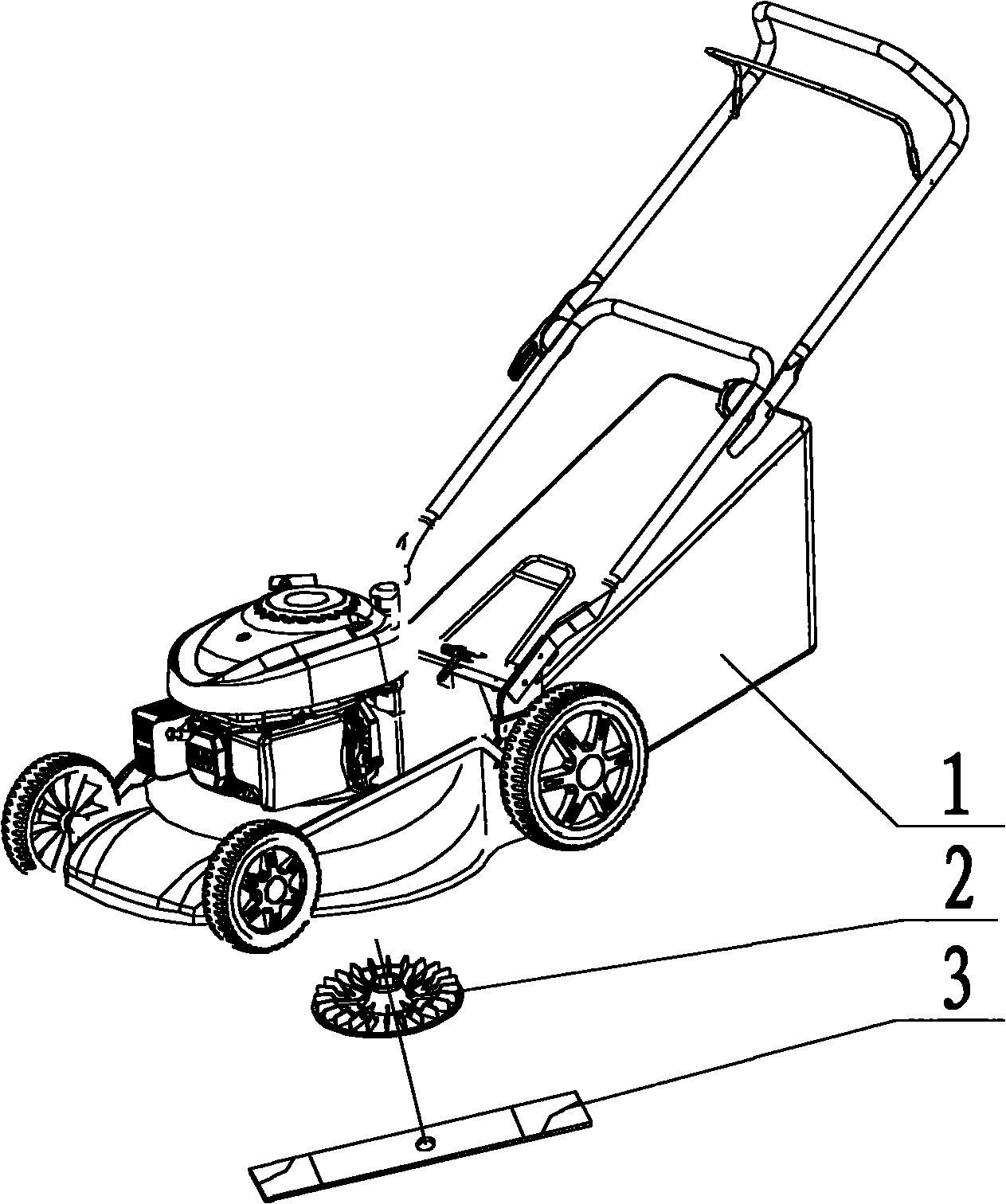

[0018] Such as figure 1 As shown, the present invention relates to a grass collecting device for a mower, comprising a power take-off shaft, a grass bag and a grass collection channel (shown in the figure) arranged on the lawn mower 1, and also includes a grass collection fan 2, The grass collecting fan 2 is arranged on the power output shaft of the lawn mower 1;

[0019] Because the grass collecting fan 2 is set, the grass collecting fan 2 is arranged on the power take-off shaft, and when the power take-off shaft carries out the power output, the mowing blade 3 on it can rotate at high speed, the grass on the lawn is processed, and the grass is mowed. The wind force generated by blade 3 high-speed rotation can also collect the cut grass in the grass bag through the grass collection channel, but the wind force produced is often not strong enough; Driven by the power take-off shaft to rotate at a high speed, the high-speed rotation of the grass collecting fan 2 also produces a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com