High-strength glass fiber-reinforced plastic pipeline and production method thereof

A fiberglass, high-strength technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of poor high temperature resistance, radial compressive strength, axial tensile strength, etc., and achieve product quality Stabilize, increase the radial compressive strength, and improve the effect of pipe body strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

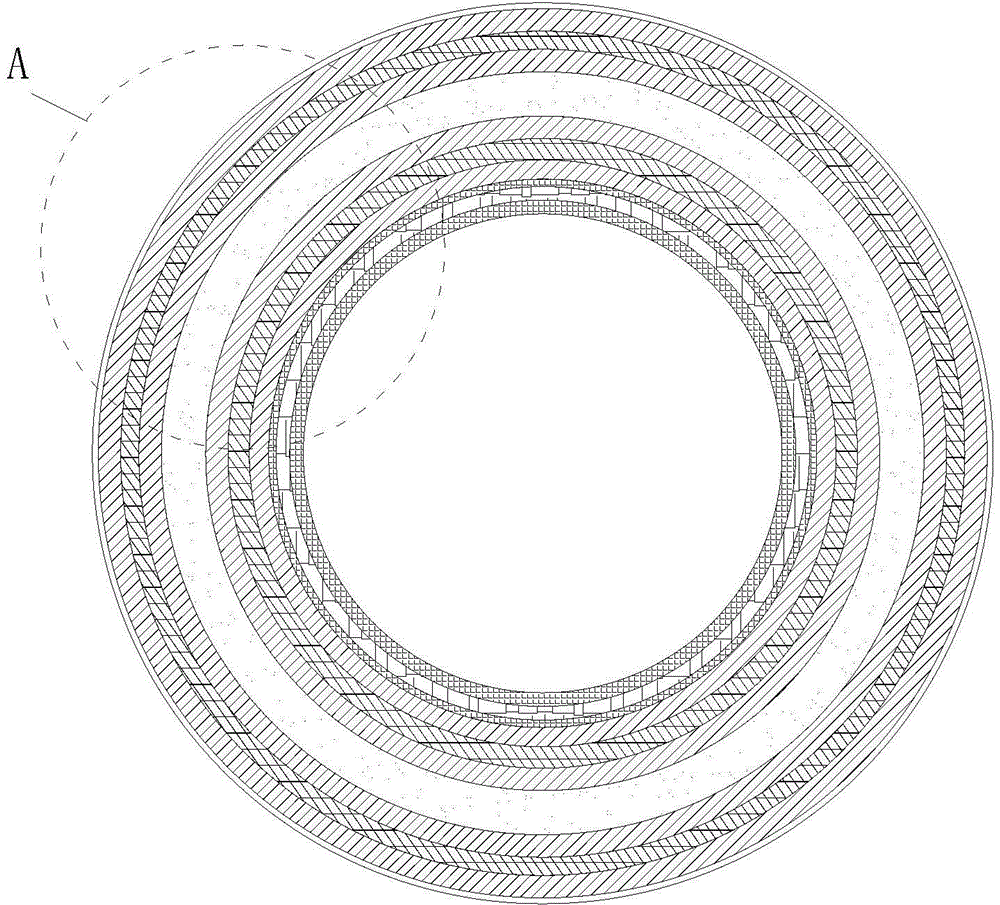

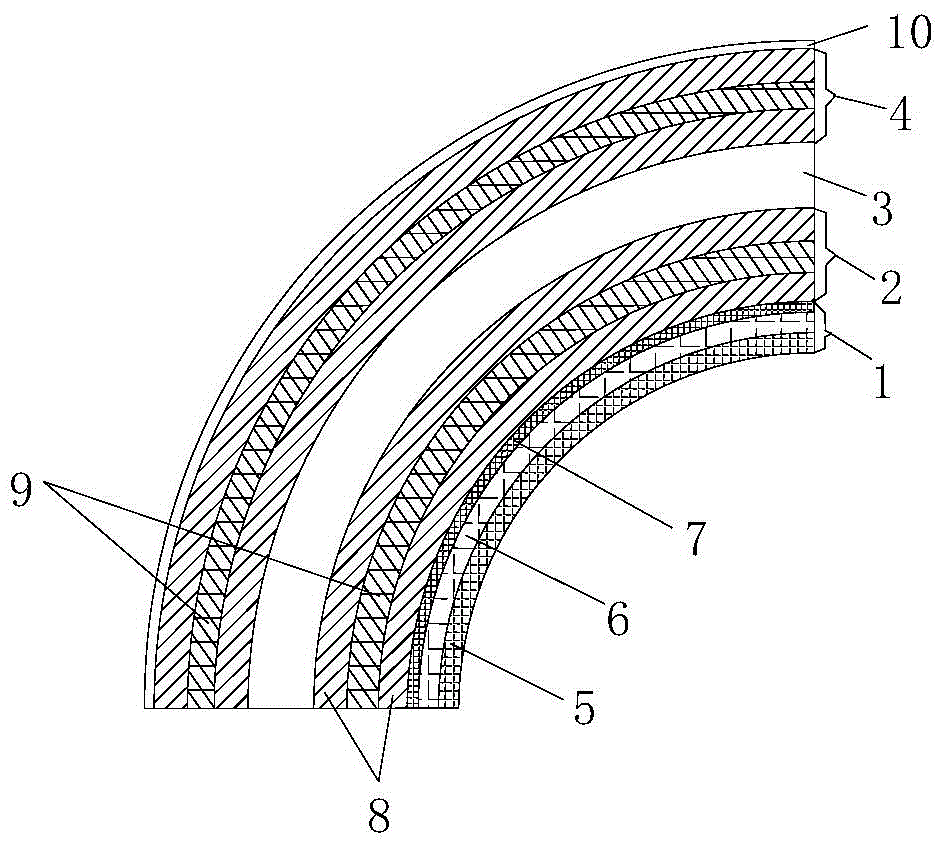

[0027] This example is a cylindrical pipe, including an inner lining layer 1, an inner structural layer 2, a middle sand layer 3, and an outer structural layer 4. The inner lining layer is composed of a glass fiber surface felt layer 5, The glass fiber knitted felt layer 6 and the mesh cloth layer 7 are formed by permeating and bonding the inner lining layer resin; the inner structure layer 2 and the outer structure layer 3 are composed of one or more layers of glass fiber yarn hoop winding layers 8, 1 One or more layers of glass fiber yarn cross-winding layer 9, the glass fiber yarn hoop winding layer is formed by hoop winding of glass fiber roving impregnated with structural layer resin with close disposable cloth yarn, The glass fiber yarn cross-winding layer is formed by winding the glass fiber roving impregnated with the resin of the structural layer in a cross-winding manner that requires multiple yarns to be separated. The hoop winding layer and the cross winding layer s...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, except that the inner lining layer resin is uniformly prepared by mixing the following raw materials according to the mass ratio of unsaturated polyester resin: accelerator: curing agent = 100:1.15:1.6 ; The structural layer resin is prepared by uniformly mixing the following raw materials according to o-ben or m-ben unsaturated polyester resin: accelerator: curing agent = 100:0.85:1.2. Sand sticky resin is prepared by uniformly mixing the following raw materials according to the mass ratio of o-ben or m-ben unsaturated polyester resin: accelerator: curing agent = 100:2.0:2.4. The ratio of the raw material components of the structural layer resin and sand-bonded resin is flexibly adjusted according to the season, ambient temperature, product type, etc. For the same batch of products, the ratio of accelerator and curing agent in the raw material formula of sand-bonded resin It should be higher than the ratio of accel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com