Investment casting mold cavity cleaning method based on selected area laser powder sintering rapid proto-typing technology application

A selective laser and investment casting technology, applied in casting and forming equipment and other directions, can solve problems such as difficult to completely ablate, inclusion of local shapes, casting pores, etc., to improve cleanliness, quality assurance, and easy operation and implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

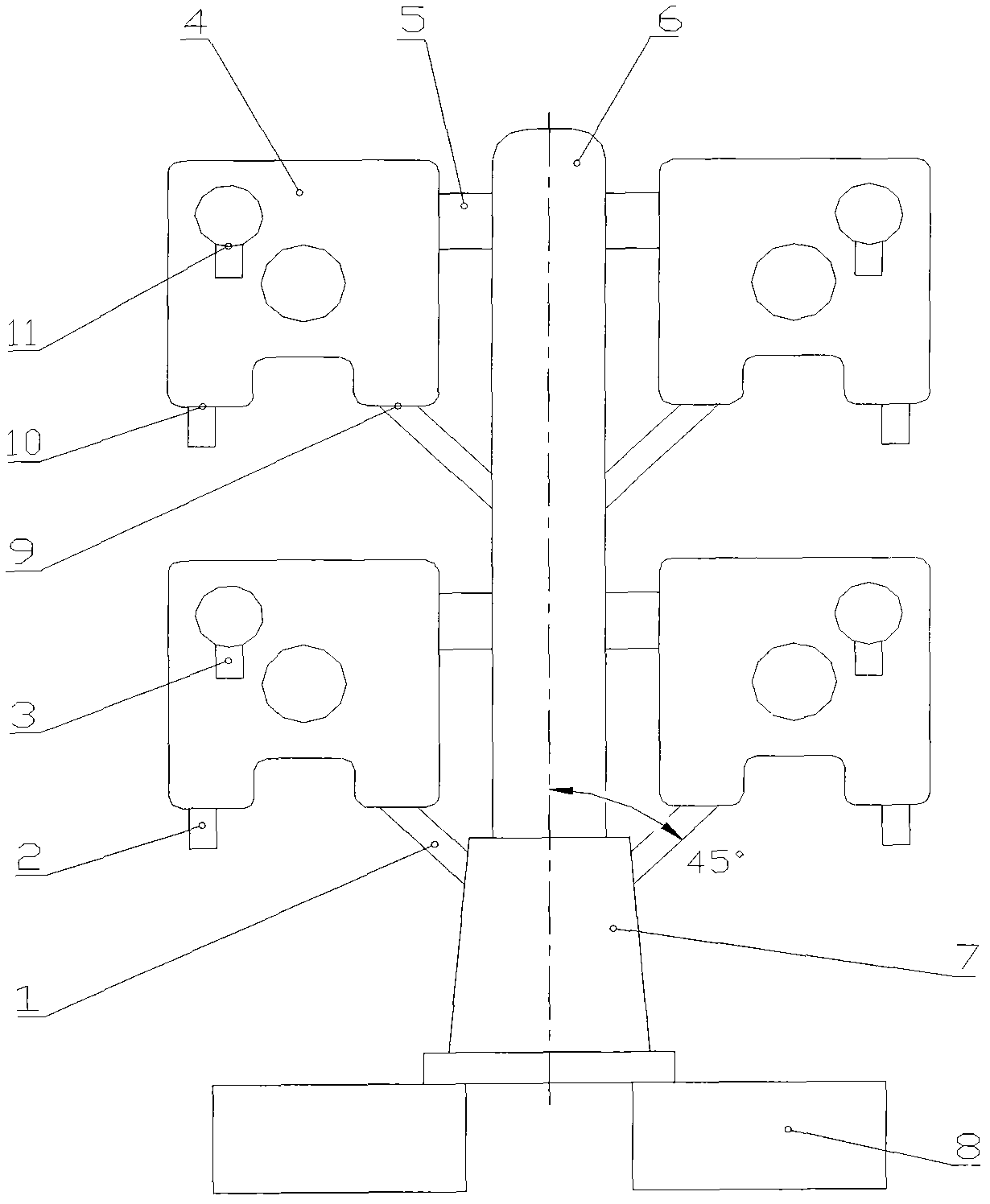

[0018] exist figure 2 In the module assembly process, the position of the wax mold (4) in the module is determined, and when the mouth of the sprue cup (7) faces upward, the wax mold (4) has a top (9), a top (10) and a second Top (11).

[0019] 1. The specific method of welding slag discharge channel is:

[0020] exist figure 2 Among them, the slag discharge channel (1) is welded between the top (9) of the wax mold (4) and the sprue cup (7) and the sprue (6), and the cross-sectional diameter of the slag discharge channel (1) is about 1 / 3~3 / 4 of the top wall thickness of the mold (4), the length is to form an angle of about 45° with the axis of the sprue (6) and the sprue cup (7), and it is beneficial to the liquid wax mold during the baking process (4) drainage exclusion is appropriate.

[0021] 2. The specific method of welding the slag collector is:

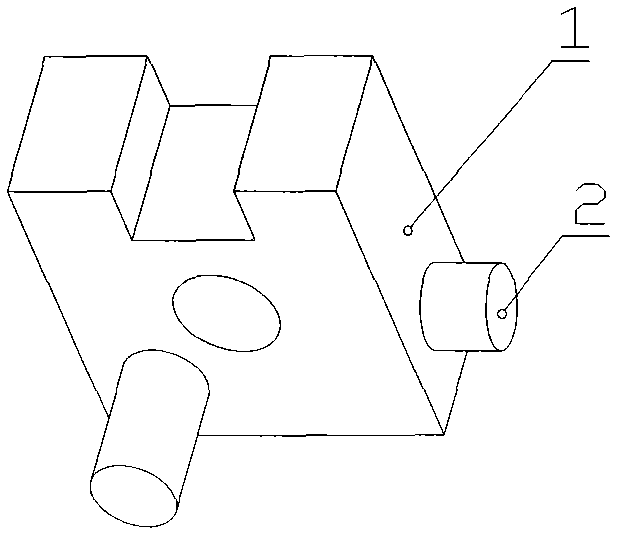

[0022] exist figure 2 Among them, the top (10) and secondary top (11) of the wax pattern (4) weld the slag trap (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com