Preparation method of glyceryl biological fuel additives

A biofuel and additive technology, which is applied in the preparation of fuel additives, organic compounds, dehydration of hydroxyl-containing compounds to prepare ethers, etc., can solve the problems of low cetane number, high density, and insignificant effect, and achieve clean combustion and emission. Improved combustion performance and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

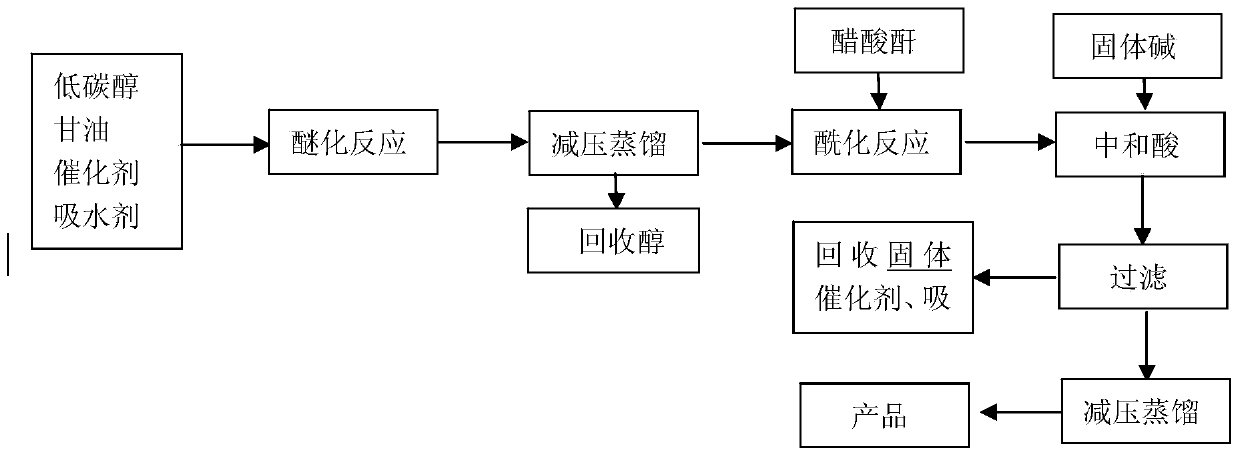

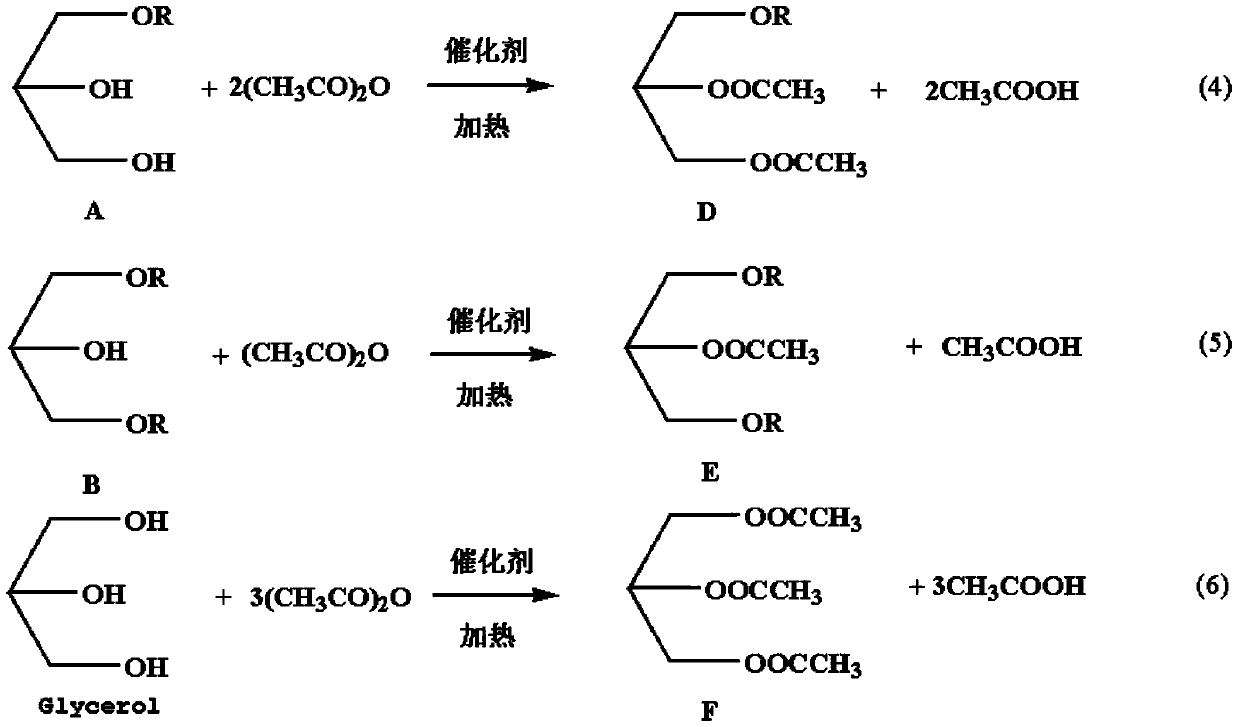

[0027] Embodiment 1: figure 1 It is the technological process of the preparation method of the glycerol-based biofuel additive, and the specific steps are as follows: Step 1: Mix 39.5g of tert-butanol, 12.6g of glycerin, 1.5g of D002 ion exchange resin and 1.5g of color-changing silica gel in an autoclave. Step 2 Seal the autoclave. Before the reaction starts, replace the air in the autoclave with nitrogen gas, increase the nitrogen pressure until the initial pressure in the autoclave is 1MPa, control the temperature of the etherification reaction at 90°C, and keep the self-boosting pressure in the autoclave during the reaction. Time 8h.

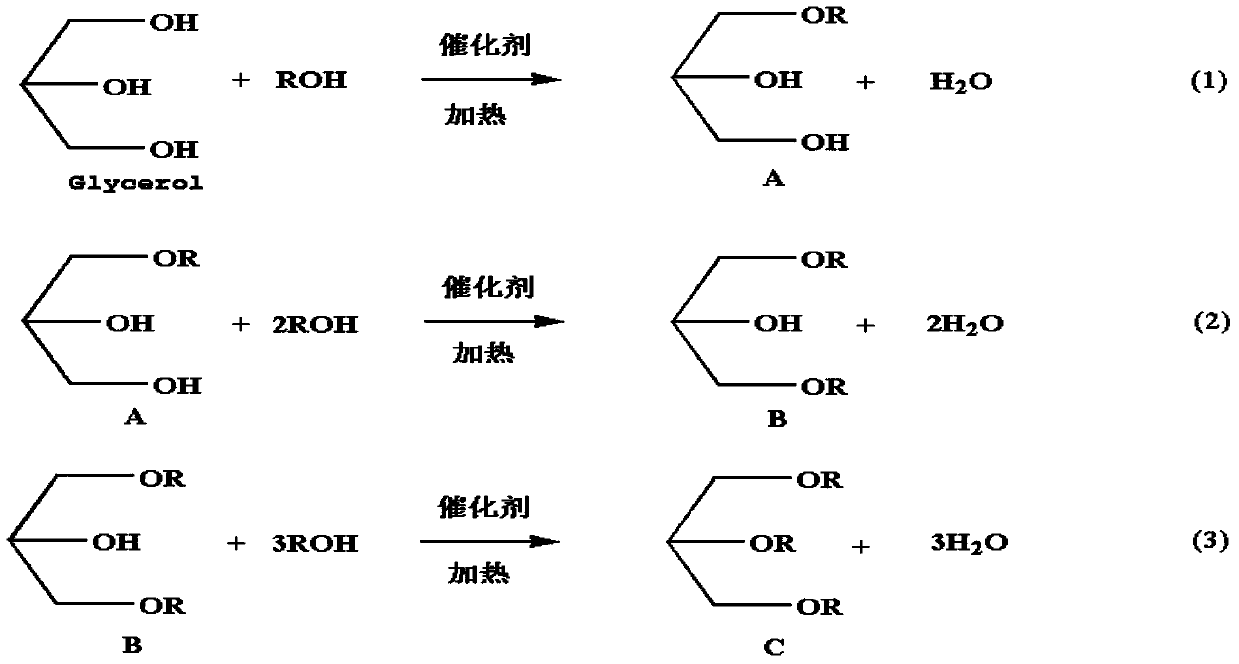

[0028] figure 2 It is the reaction formula of the etherification process, wherein ROH represents a lower alcohol, and A, B, and C represent glycerol-derived monoglycerol, diglyceride, triglyceride and isomers.

[0029] Step 3 After the reaction is over, cool down the pressure vessel with an ice-water bath, then vent the gas in the vesse...

Embodiment 2

[0038] Example 2: Step 1 Mix 32.9g of propanol, 12.6g of glycerin, 1.4g of activated carbon-supported phosphotungstic acid catalyst and 1.5g of water-absorbing resin in an autoclave.

[0039] Step 2 Seal the autoclave, replace the air in the autoclave with methane, increase the methane pressure until the initial pressure in the autoclave is 3MPa, control the reaction temperature at 95°C, and the reaction time is 9h.

[0040] Step 3 is the same as Step 3 in Example 1.

[0041]Step 4 Add the liquid obtained after distilling off the alcohol in step 3 into the acylation reaction device, and add 21.8 g of acetic anhydride dropwise to carry out the acylation reaction. The acylation temperature is 140° C., and the acylation time is 2 hours.

[0042] Step 5 After adding anhydrous sodium carbonate to neutralize to neutrality, filter to recover the catalyst and water-absorbing agent, and distill the liquid mixture under reduced pressure to obtain the target product. The distillation t...

Embodiment 3

[0044] Example 3: Step 1 Mix 12.0g of isopropanol, 9.2g of glycerin, 1.1g of macroporous network resin GD001 and 1.4g of activated alumina in an autoclave.

[0045] Step 2 Seal the autoclave, replace the air in the autoclave with nitrogen, increase the nitrogen pressure until the initial pressure in the autoclave is 4MPa, control the reaction temperature at 80°C, and react for 10 hours.

[0046] Step 3 is the same as Step 3 in Example 1.

[0047] Step 4 Add the liquid obtained by distilling off the alcohol in step 3 to the acylation reaction device, and add 20.1 g of acetic anhydride dropwise to carry out the acylation reaction. The acylation temperature is 120° C., and the acylation time is 2 hours.

[0048] Step 5 is the same as Step 5 in Embodiment 2.

[0049] Through gas chromatography analysis, the final hydroxyl conversion rate was 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com