A method for synthesizing polycarboxylate water reducer by raft method

A polycarboxylate and superplasticizer technology, applied in the field of polycarboxylate superplasticizers, can solve problems such as few research reports, achieve high chain transfer efficiency, mild reaction conditions, and a wide range of applicable monomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

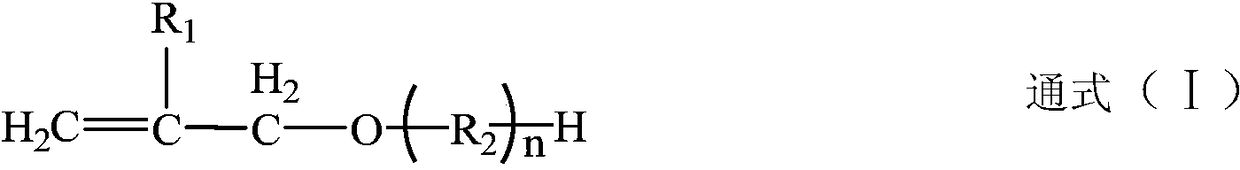

Method used

Image

Examples

Embodiment 1

[0050] Example 1 Preparation of polycarboxylic acid water reducing agent

[0051] (1) Add 120g of TPEG macromonomer to the reaction kettle, add 117.5g of water, heat the reaction kettle to 80°C in a water bath, and continue to stir;

[0052] (2) 14.4 g of acrylic acid and 40 g of water are mixed uniformly, 2.256 g of BDATT is added to the mixed solution to dissolve, and the mixture is added dropwise for 3 hours;

[0053] (3) Dissolve 0.5424g of azobisisobutylamidine dihydrochloride in 20g of water, and start dropping the solution in step (2) at a uniform rate into the reaction kettle of step (1) at the same time, and the dropping time is 3h;

[0054] (4) After the dripping is finished, continue the constant temperature stirring reaction for 4h;

[0055] (5) After the reaction, add 30% NaOH aqueous solution and 10 g of water, and cool to room temperature to obtain the polycarboxylic acid water reducing agent.

Embodiment 2

[0056] Example 2 Preparation of polycarboxylic acid water reducing agent

[0057] (1) Add 120g of TPEG macromonomer to the reaction kettle, add 137.5g of water, heat the reaction kettle to 80°C in a water bath, and continue stirring;

[0058] (2) 14.4g of acrylic acid and 30g of water are mixed uniformly, 2.256g of BDATT is added to the mixed solution to dissolve, and the mixture is dropped for 3h at a uniform speed;

[0059] (3) Dissolve 0.2282g of ammonium persulfate in 20g of water, and start dropping the solution in step (2) into the reactor of step (1) at a uniform rate at the same time, and the dropping time is 3h;

[0060] (4) After the dripping is finished, continue the constant temperature stirring reaction for 5 hours;

[0061] (5) After the reaction is completed, a 30% NaOH aqueous solution is added, and the mixture is cooled to room temperature to obtain a polycarboxylic acid water reducing agent.

Embodiment 3

[0062] Example 3 Preparation of polycarboxylic acid water reducing agent

[0063] (1) Add 120g of TPEG macromonomer to the reaction kettle, add 117.5g of water, heat the reaction kettle to 80°C in a water bath, and continue to stir;

[0064] (2) 14.4 g of acrylic acid and 40 g of water are mixed uniformly, 1.128 g of BDATT is added to the mixed solution to dissolve, and the mixture is dropped for 3 hours at a uniform speed;

[0065] (3) 0.1356g of azobisisobutylamidine dihydrochloride was dissolved in 20g of water, and the solution in step (2) was simultaneously dropped into the reactor of step (1) at a constant rate, and the dropping time was 3h;

[0066] (4) After the dripping is finished, continue the constant temperature stirring reaction for 5 hours;

[0067] (5) After the reaction, add 30% NaOH aqueous solution and 10 g of water, and cool to room temperature to obtain the polycarboxylic acid water reducing agent.

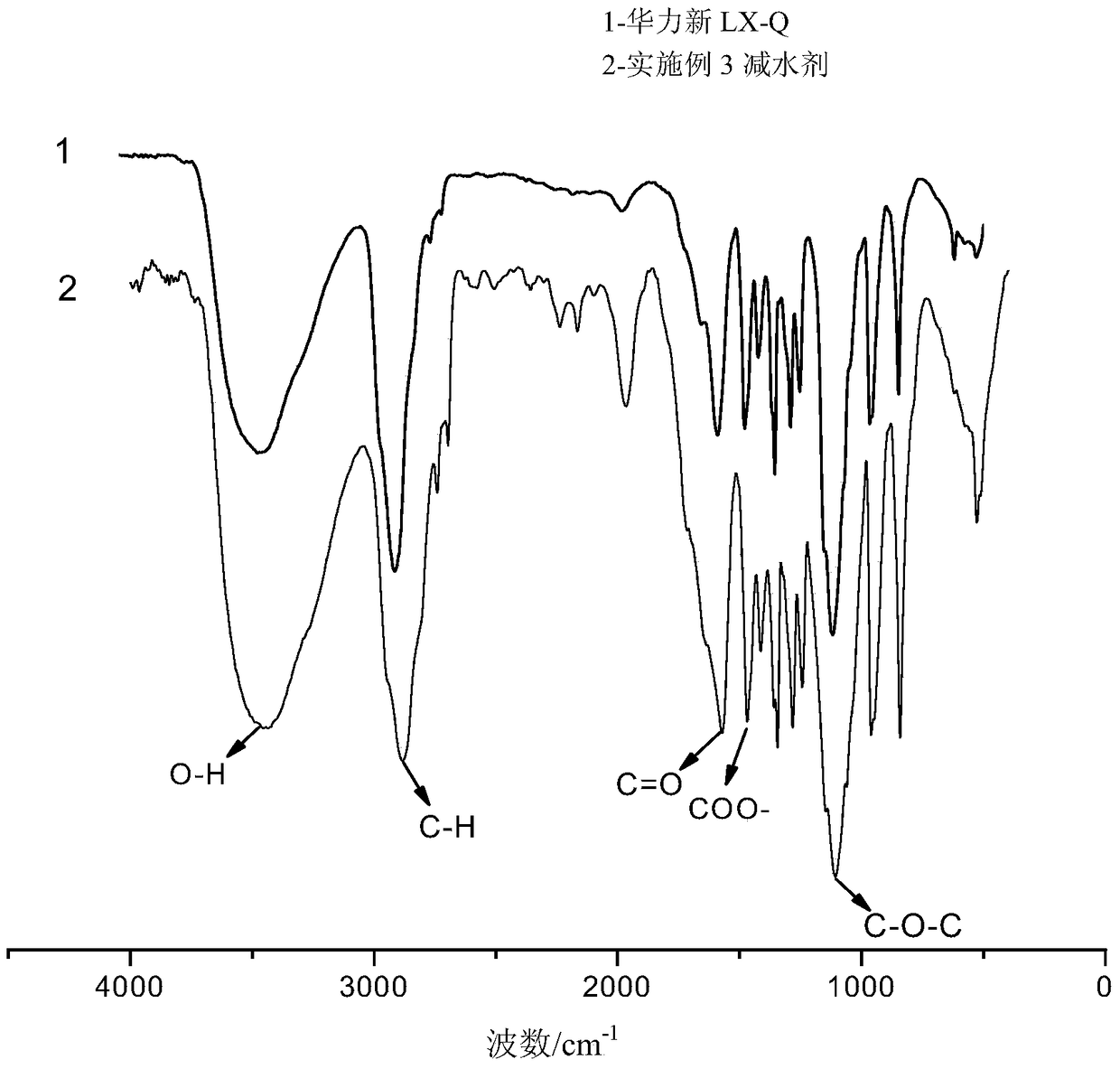

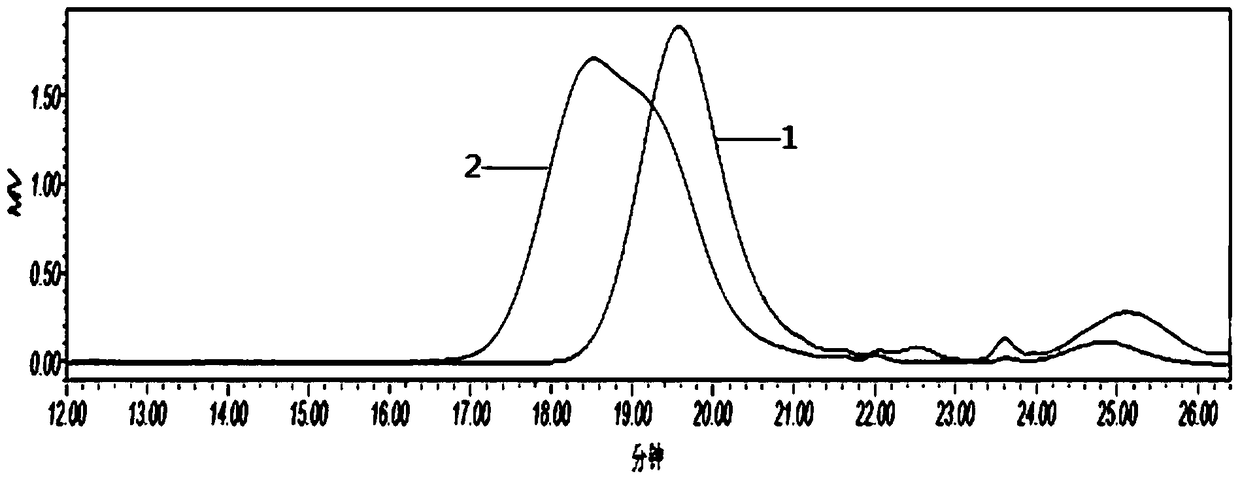

[0068] figure 1 The infrared spectra of PCE prepared in this exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com