Method for synthesizing polycarboxylate superplasticizer through RAFT method

A technology of polycarboxylic acid and water reducing agent, applied in the field of polycarboxylic acid water reducing agent, can solve problems such as few research reports, and achieve the effects of high chain transfer efficiency, simple process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation of embodiment 1 polycarboxylate water reducer

[0051] (1) Add 120g of TPEG macromonomer into the reactor, add 117.5g of water, place the reactor in a water bath and heat it to 80°C, and keep stirring;

[0052] (2) Mix 14.4g of acrylic acid and 40g of water evenly, add 2.256g of BDATT into the mixture to dissolve, and add dropwise for 3 hours at a constant speed;

[0053] (3) 0.5424g of azobisisobutylamidine dihydrochloride was dissolved in 20g of water, and the solution in step (2) was dropped into the reaction kettle of step (1) at a constant speed at the same time, and the dropping time was 3h;

[0054] (4) After the dropwise addition, the constant temperature stirring reaction was continued for 4h;

[0055] (5) After the reaction is finished, add 30% NaOH aqueous solution and 10 g of water by mass fraction, and cool down to room temperature to obtain a polycarboxylate water reducer.

Embodiment 2

[0056] The preparation of embodiment 2 polycarboxylate superplasticizer

[0057] (1) Add 120g of TPEG macromonomer into the reactor, add 137.5g of water, place the reactor in a water bath and heat it to 80°C, and keep stirring;

[0058] (2) Mix 14.4g of acrylic acid with 30g of water evenly, add 2.256g of BDATT into the mixture to dissolve, and add dropwise for 3 hours at a constant speed;

[0059] (3) 0.2282g of ammonium persulfate is dissolved in 20g of water, and the solution in step (2) is started to be added dropwise to the reaction kettle of step (1) at the same time, and the dropping time is 3h;

[0060] (4) After the dropwise addition, the constant temperature stirring reaction was continued for 5h;

[0061] (5) After the reaction is finished, add a 30% NaOH aqueous solution by mass fraction, and cool down to room temperature to obtain a polycarboxylate water reducer.

Embodiment 3

[0062] The preparation of embodiment 3 polycarboxylate superplasticizer

[0063] (1) Add 120g of TPEG macromonomer into the reactor, add 117.5g of water, place the reactor in a water bath and heat it to 80°C, and keep stirring;

[0064] (2) Mix 14.4g of acrylic acid and 40g of water evenly, add 1.128g of BDATT into the mixture to dissolve, and add dropwise at a constant speed for 3 hours;

[0065] (3) 0.1356g of azobisisobutylamidine dihydrochloride was dissolved in 20g of water, and the solution in step (2) was dropped into the reactor of step (1) at a constant speed at the same time, and the dropping time was 3h;

[0066] (4) After the dropwise addition, the constant temperature stirring reaction was continued for 5h;

[0067] (5) After the reaction is finished, add 30% NaOH aqueous solution and 10 g of water by mass fraction, and cool down to room temperature to obtain a polycarboxylate water reducer.

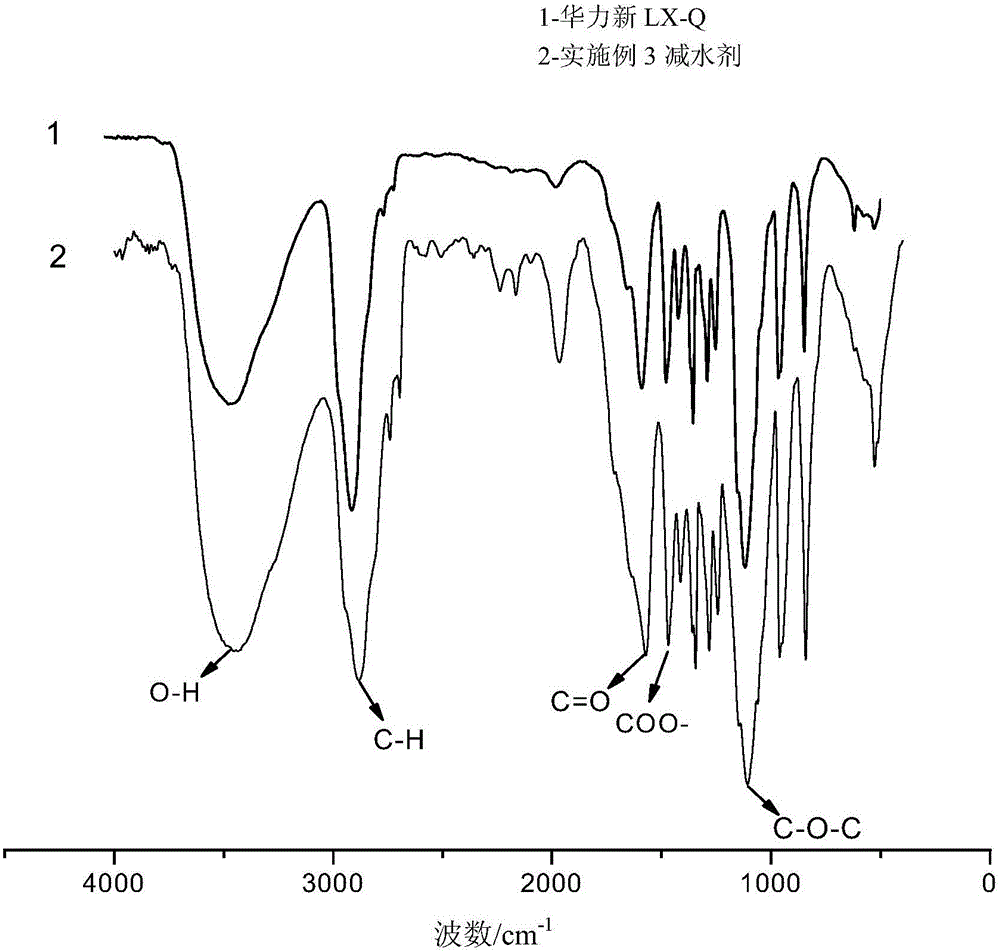

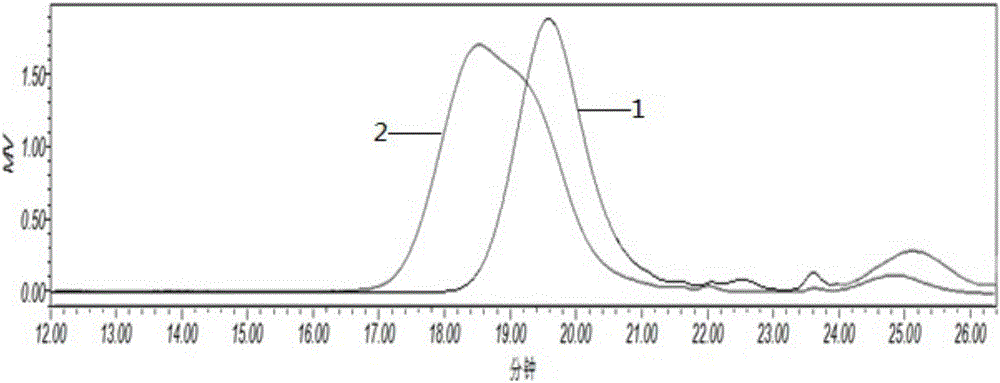

[0068] figure 1 Infrared spectrum comparison chart of PCE prepared f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com