Poly(carbonate-ether) polyurethane resin and preparation method thereof and leather pulp

A technology of polyurethane resin and polyurethane leather is applied in the fields of poly-polyurethane resin and its preparation method and leather pulp, which can solve the problems of hazards, dependence on catalysts, etc., and achieve simple production process, excellent tensile strength and elongation at break, The effect of high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

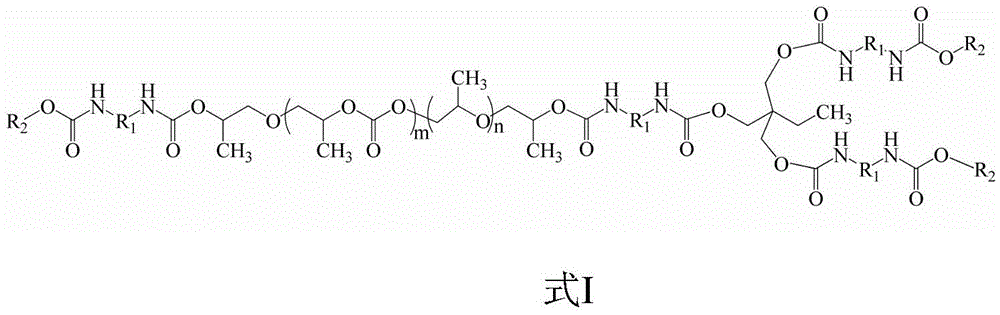

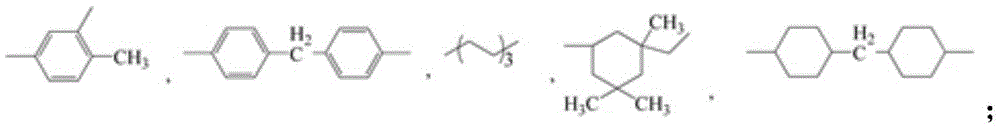

[0049] The preparation of poly(carbonate-ether) type polyurethane resin (m=10, n=5):

[0050] Add 60g of poly(carbonate-ether) glycol (number-average molecular weight 1500) in the there-necked flask, heat up to 110°C, decompress for 1h; under nitrogen protection, cool down to 65°C, add 8.5g of butanediol, divide Add 168g of dimethylformamide, 0.032g of BiCAT4130 catalyst and 32.4g of dicyclohexylmethane diisocyanate in three batches. After each batch is added, react for 1h. After the three batches of reaction are completed, heat up to 80°C and continue to Add 3.6 g of trimethylolpropane into the three-necked flask, stir and react for 1 h, add 0.3 g of methanol, and continue the reaction for 0.5 h to obtain poly(carbonate-ether) polyurethane resin.

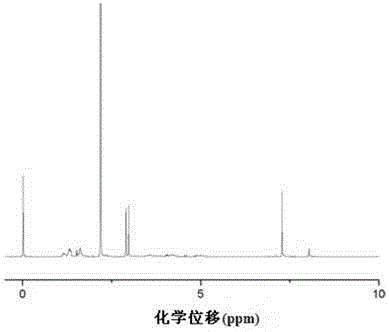

[0051] figure 1 For the proton nuclear magnetic resonance spectrum (CDCl) of the poly(carbonate-ether) type polyurethane resin prepared in embodiment 1 3 ), as can be seen from the figure, HNMR (CDCl 3 ):1.14ppm, 1.34ppm, 1.51pp...

Embodiment 2

[0053] The preparation of poly(carbonate-ether) type polyurethane resin (m=43, n=9):

[0054] Add 105g of poly(carbonate-ether) glycol (number average molecular weight 5000) into the there-necked flask, heat up to 110°C, decompress for 1.5h; under nitrogen protection, cool down to 70°C, add 14.6g of ethylene glycol Molecular chain extender, add 235g of dimethylformamide, 0.076g of BiCAT4130 catalyst and 52.8g of 2,4-toluene diisocyanate in three batches, after each batch is added, react for 2h, after three batches of reaction, Raise the temperature to 85°C, continue to add 5.3g of trimethylolpropane into the three-necked flask, stir for 3 hours, add 0.8g of methanol, and continue to react for 2 hours to obtain a poly(carbonate-ether) polyurethane resin.

[0055] The proton nuclear magnetic resonance spectrum of the poly(carbonate-ether) polyurethane resin that embodiment 2 prepares, HNMR (CDCl 3 ):1.16ppm, 1.38ppm, 1.54ppm, 1.67ppm, 2.01ppm, 2.20ppm, 2.31ppm, 2.42ppm, 2.93ppm...

Embodiment 3

[0057] The preparation of poly(carbonate-ether) type polyurethane resin (m=6, n=21):

[0058] Add 76g of poly(carbonate-ether) glycol (number-average molecular weight 2000) into the three-necked flask, raise the temperature to 110°C, and depressurize for 1h; under nitrogen protection, cool down to 68°C, add 9.7g of diethylene glycol Diol small molecule chain extender, add 186g of dimethylformamide, 0.046g of BiCAT4130 catalyst and 39.8g of isophorone diisocyanate in three batches, after each batch is added, react for 1.5h, three batches of reaction After completion, the temperature was raised to 82° C., and 4.1 g of trimethylolpropane was continuously added into the three-necked flask, stirred for 2 h, 0.5 g of methanol was added, and the reaction was continued for 1 h to obtain a poly(carbonate-ether) polyurethane resin.

[0059] The proton nuclear magnetic resonance spectrum of the poly(carbonate-ether) polyurethane resin that embodiment 3 prepares, HNMR (CDCl 3 ):1.10ppm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com