Coloring pigment bottle structure

A paint and pen coating technology, applied in the clamping device, closing, packaging, etc., can solve the problems of low frequency of use of color usage, low mixing efficiency of glass rods, and glass rods that cannot be used universally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

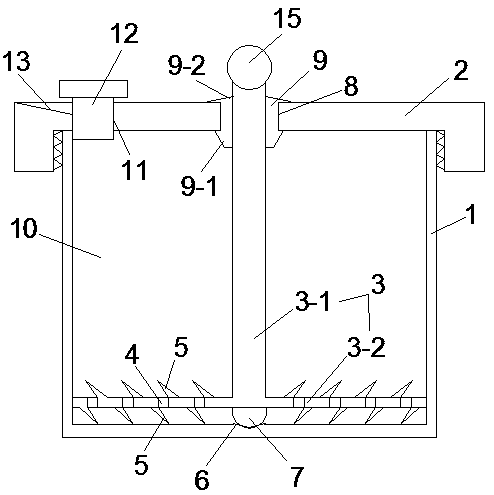

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

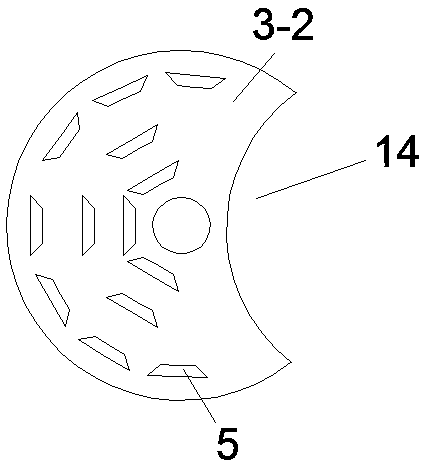

[0021] Such as figure 1 , figure 2 As shown, the embodiment of the present invention includes a bottle body 1, a cover body 2 and a stirring structure 3. The bottle mouth of the bottle body 1 is screwed to the cover body 2 through a screw thread, and the stirring structure 3 includes a bottle body extending through the cover body 2 to the bottle body. The stirring rod 3-1 at the bottom of 1, the lower end of the stirring rod 3-1 is provided with a stirring plate 3-2, the upper end of the stirring rod 3-1 is provided with a handle 15, and the stirring plate 3-2 is provided with a through hole 4. Scrapers 5 are provided at the upper and lower ends of the through hole 4. The scraper 5 is inclined towards the axial centerline of the through hole 4. When the paint is left for a long time, the paint will be layered, and the main components of the paint will be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com