Biological organic fertilizer and preparation method thereof

A bio-organic fertilizer and cake fertilizer technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., to achieve a good agricultural ecosystem, improve soil physics, and increase fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

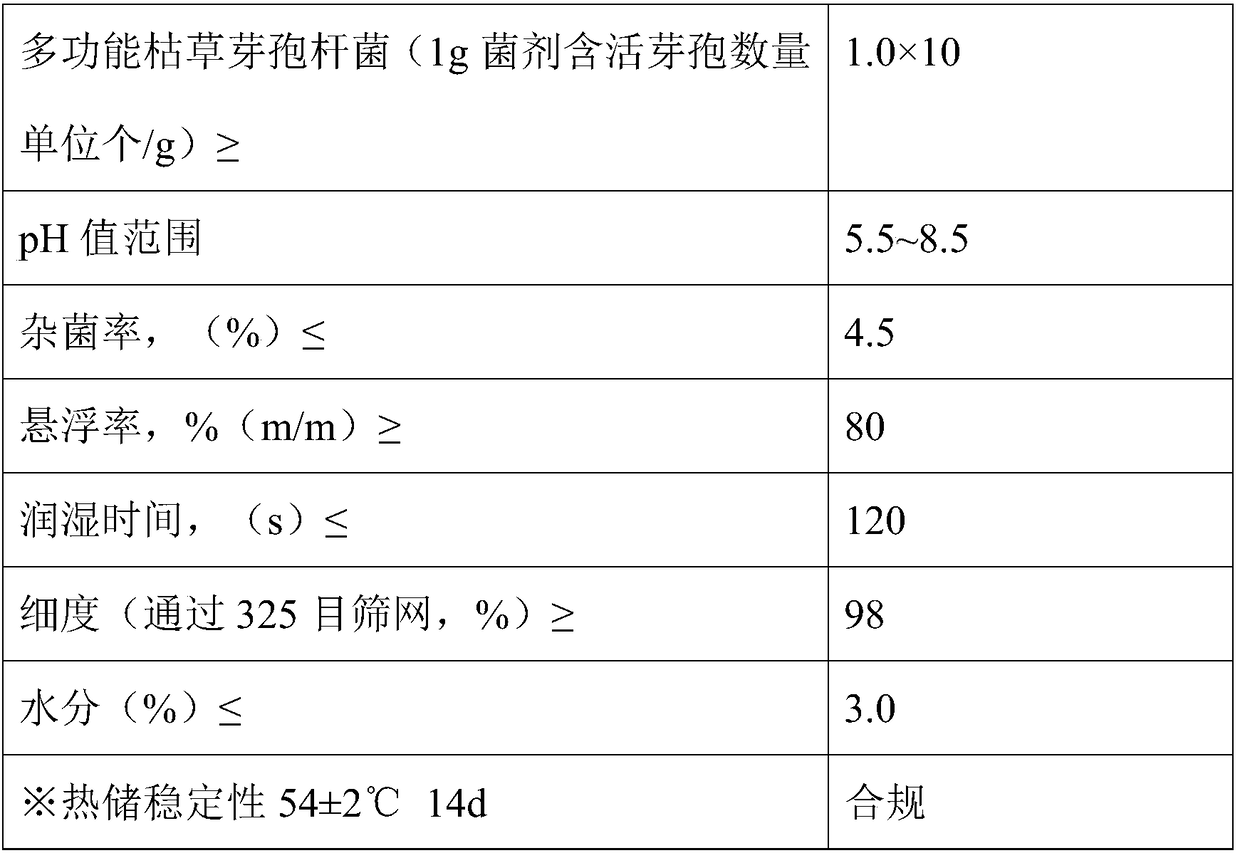

[0055] The present embodiment relates to a kind of preparation method of multifunctional Bacillus subtilis bacterial agent, it comprises the following steps:

[0056] 1), prepare bacterial classification, be about to add 10 Kirschner flask seeds and aseptic water to make bacterial suspension, inoculate in the large tank under aseptic condition;

[0057] 2) Fermentation medium, namely yeast powder with a content of 2.2w / v% and a fineness ≥ 80 meshes, industrial-grade cornstarch with a content of 1.5w / v%, industrial-grade calcium carbonate with a content of 0.5w / v%, The volume of industrial grade potassium dihydrogen phosphate with a content of 0.24w / v%, industrial grade ammonium sulfate with a content of 0.6w / v%, and industrial grade defoamer with a content of 0.055w / v% after sterilization is the fermenter In a tank with 65% volume, the pH before sterilization is 7.15~7.7; then keep the ventilation volume at 1:0.5 during the period of 0~8h, and keep the ventilation volume at 1:...

Embodiment 2

[0071] 1. Raw material pretreatment:

[0072] Dried the Ningnan bacteria residue, crushed it, and sieved it with a 40-mesh sieve; the peat soil was broken and sieved through a sieve hole of 0.4-4cm by a turning machine;

[0073] 2. Mixing:

[0074] (1) Use a forklift to put 8t of coal gangue, 6t of pig manure, 55t of peat soil, 20t of rice husk powder, 12t of fungus residue, 80kg of multifunctional Bacillus subtilis, and 2t of zeolite powder into the above raw materials in sequence from the bottom to the top. Spread evenly in the middle of the fermentation tank, use a manual throwing machine to turn the above mixed materials back and forth until all the materials are mixed evenly;

[0075] (2) Mix the materials and make them level. The height of the entire fermented materials is not higher than 80 cm. At this time, use an automatic throwing machine to overturn, add water to the materials while overturning, and calculate the added moisture according to the rate of 3t / h. It is...

Embodiment 3

[0078] The bean cake is dried, crushed, and sieved through a 40-mesh sieve; the peat soil is broken and sieved through a 0.4-4cm sieve hole by a turning machine;

[0079] 2. Mixing:

[0080] (1) Use a forklift to mix 18t of coal gangue, 8t of chicken manure, 120t of peat soil, 28t of corn stalks, 18t of bean cake, 130kg of multifunctional Bacillus subtilis, and 4t of zeolite powder in order from the bottom to the top. Lay it in the middle of the fermentation tank, use a manual turning machine to turn the above mixed materials back and forth until all the materials are mixed evenly;

[0081] (2) Mix the materials and make them level. The height of the entire fermented materials is not higher than 80 cm. At this time, use an automatic throwing machine to overturn, add water to the materials while overturning, and calculate the added moisture according to the rate of 3t / h. It is advisable to control the time at 10-12h, so that the relative moisture of the whole fermentation mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com